Soaping enzyme for denim fabric washing and preparation technology thereof

A technology for denim fabric and preparation process, which is applied in the field of soaping enzyme for denim fabric washing and its preparation process, can solve the problems of clogging sewage treatment tank, fiber strength damage, wearing discomfort, etc., so as to reduce the discharge of phosphorus element and reduce the strength The effect of large damage and shortened treatment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

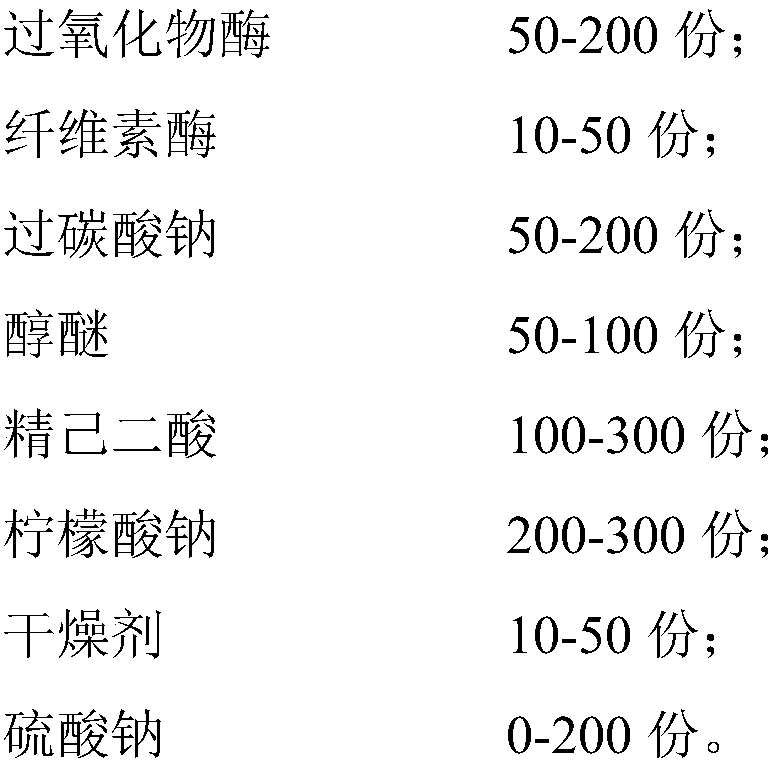

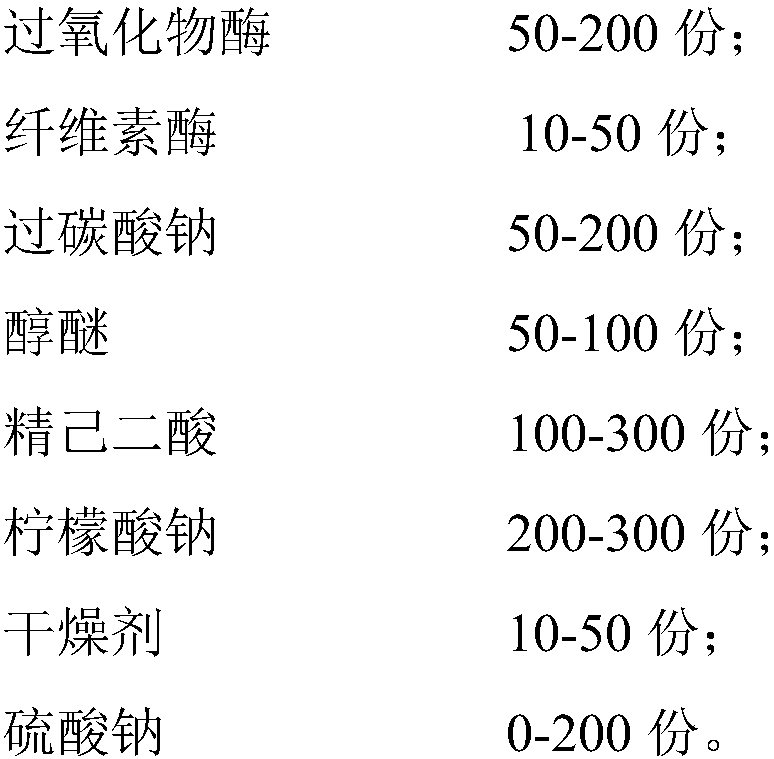

[0026] A kind of soaping enzyme that is used for denim fabric washing, its preparation method is as follows

[0027] 50 parts of peroxidase, 20 parts of cellulase, 50 parts of sodium percarbonate, 350 parts of refined adipic acid, 350 parts of sodium citrate, 150 parts of alcohol ether, and 30 parts of desiccant are mixed with all raw materials Put it into a stainless steel double-helix conical mixing tank, then stir at a speed of 35r / min for 15 minutes, then release 50-100 parts from the bottom of the mixing tank, put them in from the top of the tank, and continue stirring for 10 minutes. After stirring evenly, stir while stirring Filling while feeding to obtain soaping enzyme.

Embodiment 2

[0029] A kind of soaping enzyme that is used for denim fabric washing, its preparation method is as follows

[0030] 50 parts of peroxidase, 20 parts of cellulase, 50 parts of sodium percarbonate, 300 parts of refined adipic acid, 350 parts of sodium citrate, 200 parts of alcohol ether, and 30 parts of desiccant are mixed with all raw materials Put it into a stainless steel double-helix conical mixing tank, then stir at a speed of 35r / min for 15 minutes, then release 50-100 parts from the bottom of the mixing tank, put them in from the top of the tank, and continue stirring for 10 minutes. After stirring evenly, stir while stirring Filling while feeding to obtain soaping enzyme.

Embodiment 3

[0032] A kind of soaping enzyme that is used for denim fabric washing, its preparation method is as follows

[0033] 100 parts of peroxidase, 50 parts of cellulase, 100 parts of sodium percarbonate, 300 parts of refined adipic acid, 300 parts of sodium citrate, 100 parts of alcohol ether, and 50 parts of desiccant are mixed with all raw materials Put it into a stainless steel double-helix conical mixing tank, then stir at a speed of 35r / min for 15 minutes, then release 50-100 parts from the bottom of the mixing tank, put them in from the top of the tank, and continue stirring for 10 minutes. After stirring evenly, stir while stirring Filling while feeding to obtain soaping enzyme.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com