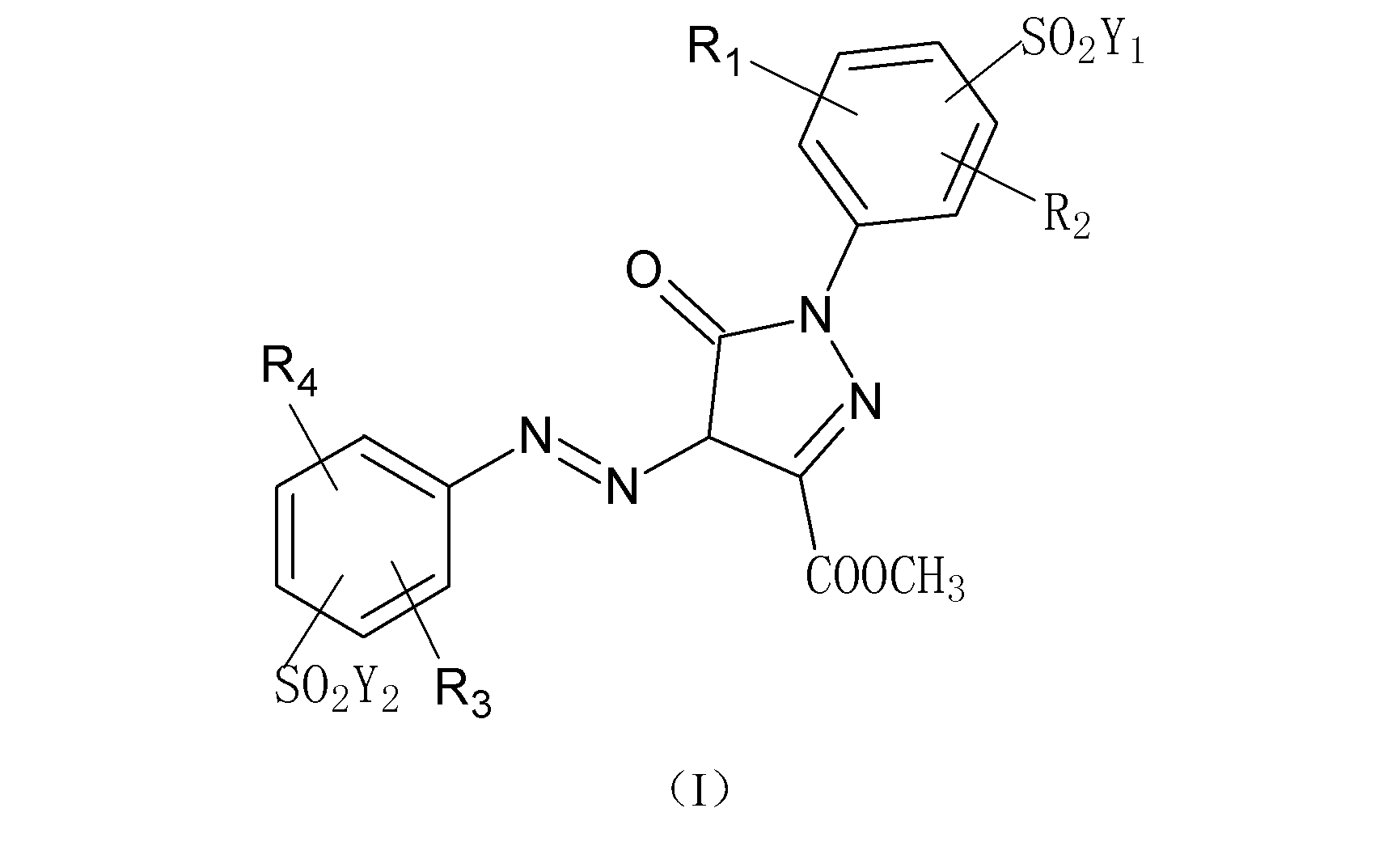

Yellow double-reactive-group dye compound, preparation method and composition thereof

A technology of dual reactive dyes and compounds, which is applied in the field of yellow dual reactive dye compounds, can solve the problems of sunlight, poor rubbing fastness, old textile appearance, staining of dyes, etc., and achieve good light fastness and bright colors , Good whitening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

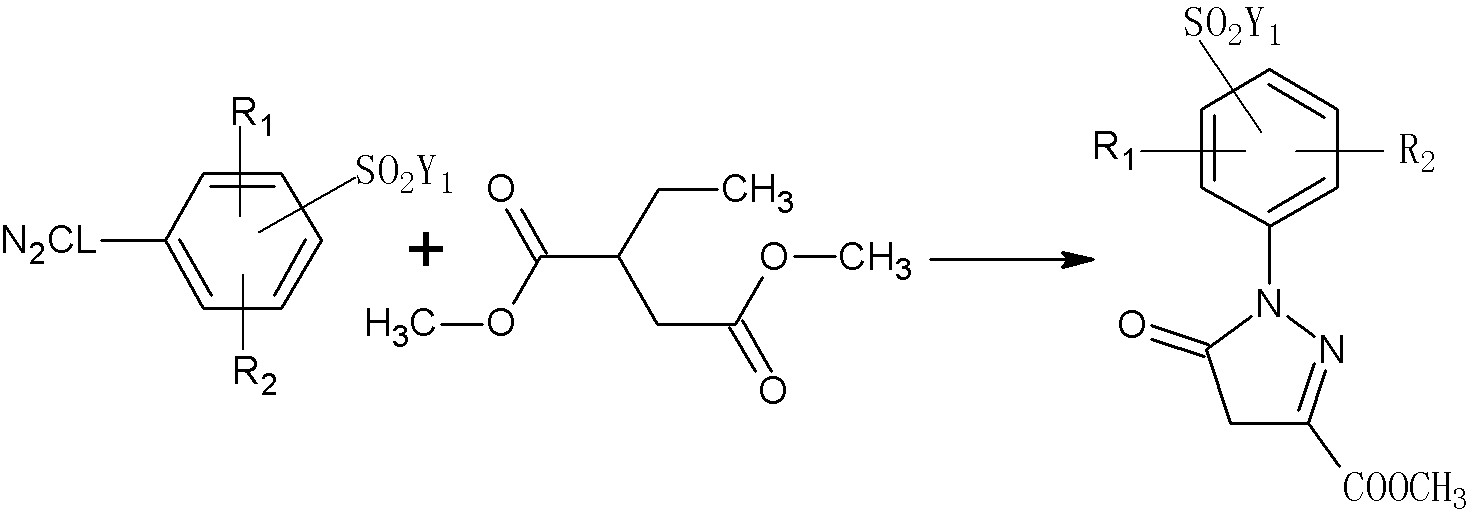

Method used

Image

Examples

Embodiment 1

[0047] Example 1: Detailed preparation method of dye (I-1).

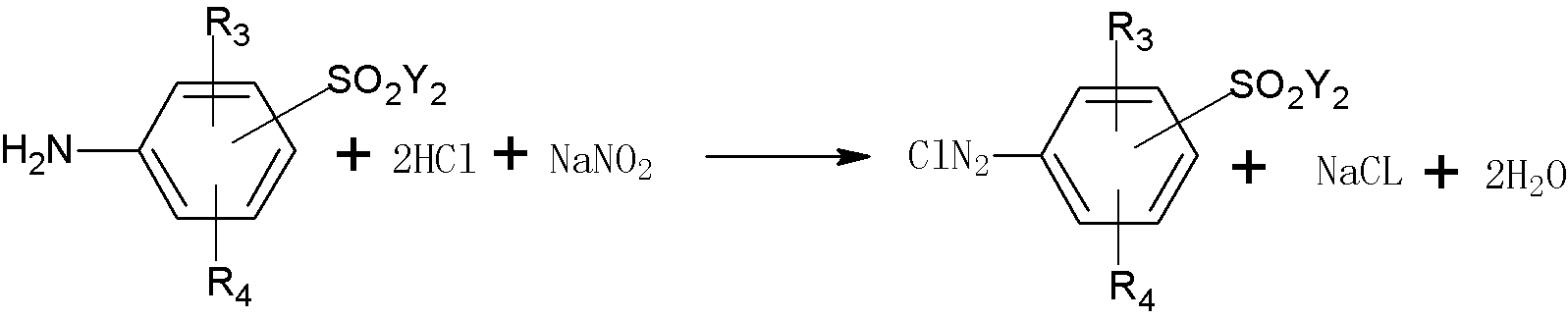

[0048] (1) The first diazotization reaction of para-ester: Weigh 29.3g of para-ester dry powder, add 50g of ice, add 100g of water and beat for one hour, then add 13.5g of 30% hydrochloric acid, stir for 1 minute, and dissolve the clear 24.3g of 30% sodium nitrite is slowly added dropwise into the solution for diazotization reaction, the temperature is controlled at 0-20°C and the pH value is controlled at 1.0-2.0 during the dropping process. And make the starch potassium iodide test paper microscopically blue, and the Congo red test paper microscopically blue. After the sodium nitrite solution is added dropwise, keep the temperature at 0-20°C, control the pH value at 1.0-2.0, and then stir and react for 30 minutes, then use sulfamic acid to balance the excess sodium nitrite, and perform the first diazotization reaction of the para-ester The formula is as follows.

[0049] (2) Coupling and ring-closing reaction:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com