Novel acidic anti-staining soap lotion and preparation method thereof

An anti-staining soaping agent and acid technology, applied in the field of textile printing and dyeing, can solve the problems of unsatisfactory anti-staining effect, reducing the pressure of sewage treatment, unsuitable anti-staining agent, etc., so as to improve the dyeing fastness and reduce the production process. , the effect of strong dispersing and chelating ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

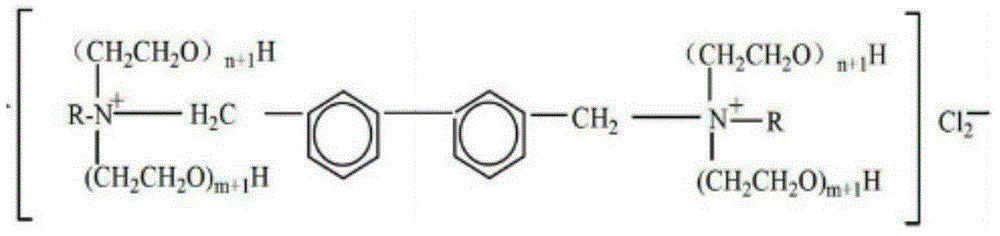

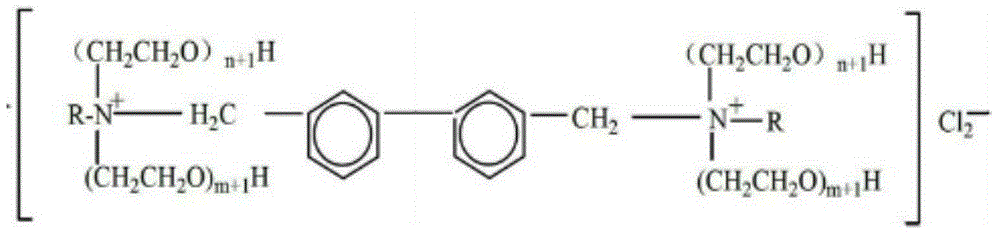

[0024] Example 1-1 Preparation of Didodecylamine Polyoxyethylene Ether Diquaternary Ammonium Salt

[0025] Add 715.6g (0.30mol) of didodecanylamine polyoxyethylene ether and 37.5g (0.15mol) of biphenyl benzyl dichloride into a four-neck flask, raise the temperature to 100°C-150°C, react for 4 hours, then cool down to 50°C , add 85.3g of deionized water, heat preservation reaction for 10h, to obtain a brown viscous liquid.

Embodiment 1-2

[0026] Embodiment 1-2 Preparation of maleic anhydride-acrylic acid-N-vinylpyrrolidone terpolymer

[0027] In a four-neck flask equipped with a reflux condenser and a dropping funnel, add 50.0 g of maleic anhydride and 55.0 g of water, heat to 60°C-70°C and stir to make it completely dissolved and transparent; add NaOH aqueous solution to adjust the pH to neutral, Continue to raise the temperature. When the temperature rises to 80°C-90°C, add 150.0g of acrylic acid, 12.5g of N-vinylpyrrolidone and 5.0g of ammonium persulfate solution dropwise at the same time. React at a constant temperature of 90°C for 6h. After the reaction is completed, adjust the pH to 3-5 with NaOH aqueous solution, and cool down to 50°C to obtain a light yellow viscous liquid.

Embodiment 1-3

[0028] Embodiment 1-3 soaping agent preparation

[0029] In a four-neck flask, add 100.0 g of didodecylamine polyoxyethylene ether bisquaternary ammonium salt and 235.0 g of deionized water, heat up to 60°C-70°C and stir evenly; add maleic anhydride-acrylic acid-N - 150.0 g of vinylpyrrolidone terpolymer and 15.0 g of carboxyethylthiosuccinic acid, and continue stirring for 30 minutes. Prepare the soaping agent used in this experiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com