Method for treating acrylic-acid-containing waste water by microwave radiation technique

A technical treatment and microwave radiation technology, which is applied in water/sewage treatment, chemical instruments and methods, textile industry wastewater treatment, etc., can solve the problems of high cost of acrylic acid wastewater, reduced reaction time, and toxic intermediate products, etc., to shorten the synthesis time , reduce pollution and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

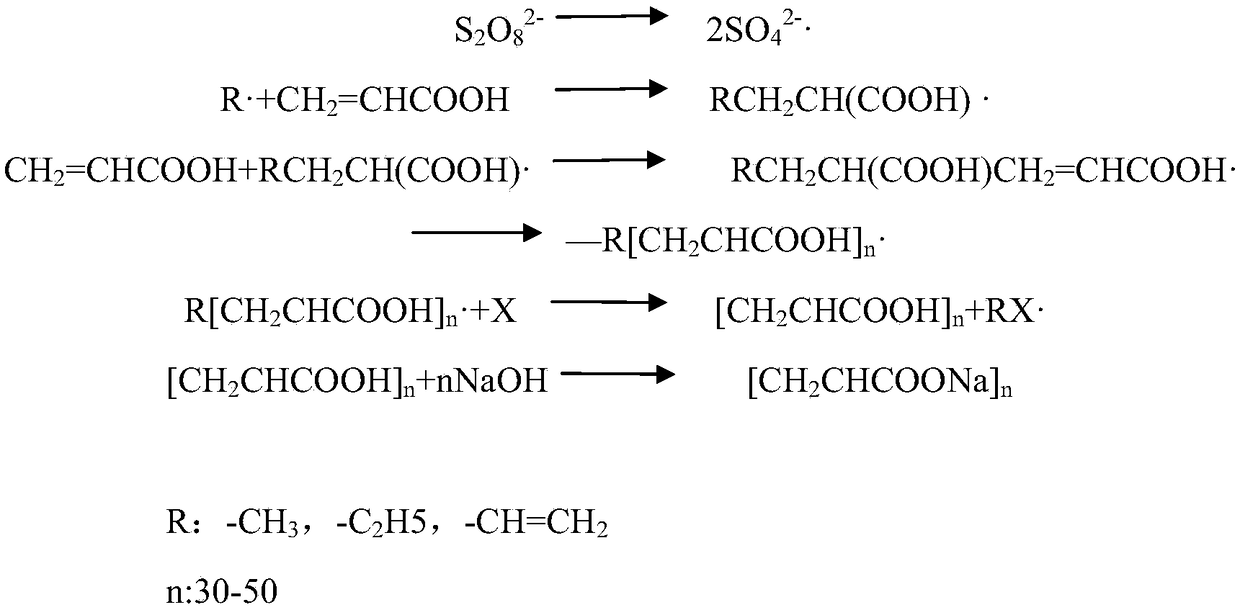

Method used

Image

Examples

Embodiment 1

[0034] Utilize microwave method to treat the waste water containing acrylic acid to prepare reactive dye soaping agent, concrete steps are:

[0035] 100g of waste water containing acrylic acid (the content of acrylic acid and its oligomers in the waste water is about 10%) is added in the four-necked flask, and another 1.2 g of initiator ammonium persulfate is dissolved in water, and the mass fraction is 10%. solution, another 20 g of acrylic acid monomers were placed in the dropping funnel; then the reaction condition parameters of the microwave reactor were set as follows: the microwave power was 500W, the reaction time was 20min, and the reaction temperature was 50°C. After temperature, start to add the initiator ammonium persulfate solution and acrylic acid monomer drop by drop. After the heating time ends, when the temperature drops below 50°C, add dropwise an aqueous NaOH solution with a mass fraction of 40% to the resulting product, adjust the pH to 7, and finally obtain...

Embodiment 2

[0037] Utilize microwave method to treat the waste water containing acrylic acid to prepare reactive dye soaping agent, concrete steps are:

[0038] 100g of waste water containing acrylic acid (the content of acrylic acid and its oligomers in the waste water is about 17%) is added in the four-necked flask, and another 1.2g of initiator ammonium persulfate is dissolved in water, and the mass fraction is 10%. The solution, another 20g of acrylic acid monomer is taken, respectively placed in the dropping funnel; then the reaction condition parameters of the microwave reactor are set as follows: the microwave power is 500W, the reaction time is 30min, and the reaction temperature is 50°C. After the temperature was fixed, the initiator ammonium persulfate solution and acrylic acid monomer were added dropwise. After the heating time ends, when the temperature drops below 50°C, add dropwise an aqueous NaOH solution with a mass fraction of 40% to the resulting product, adjust the pH t...

Embodiment 3

[0040] Utilize microwave method to treat the waste water containing acrylic acid to prepare reactive dye soaping agent, concrete steps are:

[0041] 100g of waste water containing acrylic acid (the content of acrylic acid and its oligomers in the waste water is about 17%) is added in the four-necked flask, and another 1.2g of initiator ammonium persulfate is dissolved in water, and the mass fraction is 10%. of the solution, another 20 g of acrylic acid monomers were placed in the dropping funnel; the reaction condition parameters of the microwave reactor were then set as follows: the microwave power was 500W, the reaction time was 20min, and the reaction temperature was 60°C. After the temperature was fixed, the initiator ammonium persulfate solution and acrylic acid monomer were added dropwise. After the heating time ends, when the temperature drops below 50°C, add dropwise an aqueous NaOH solution with a mass fraction of 40% to the resulting product, adjust the pH to 7, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com