High-efficiency environment-friendly acidic soap washing agent, and preparation method thereof

An environment-friendly, soaping agent technology, applied in the directions of surface active detergent composition, thioether preparation, detergent composition, etc., can solve problems such as environmental eutrophication, achieve strong deposition ability, good soaping effect, reduce The effect of discharge pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

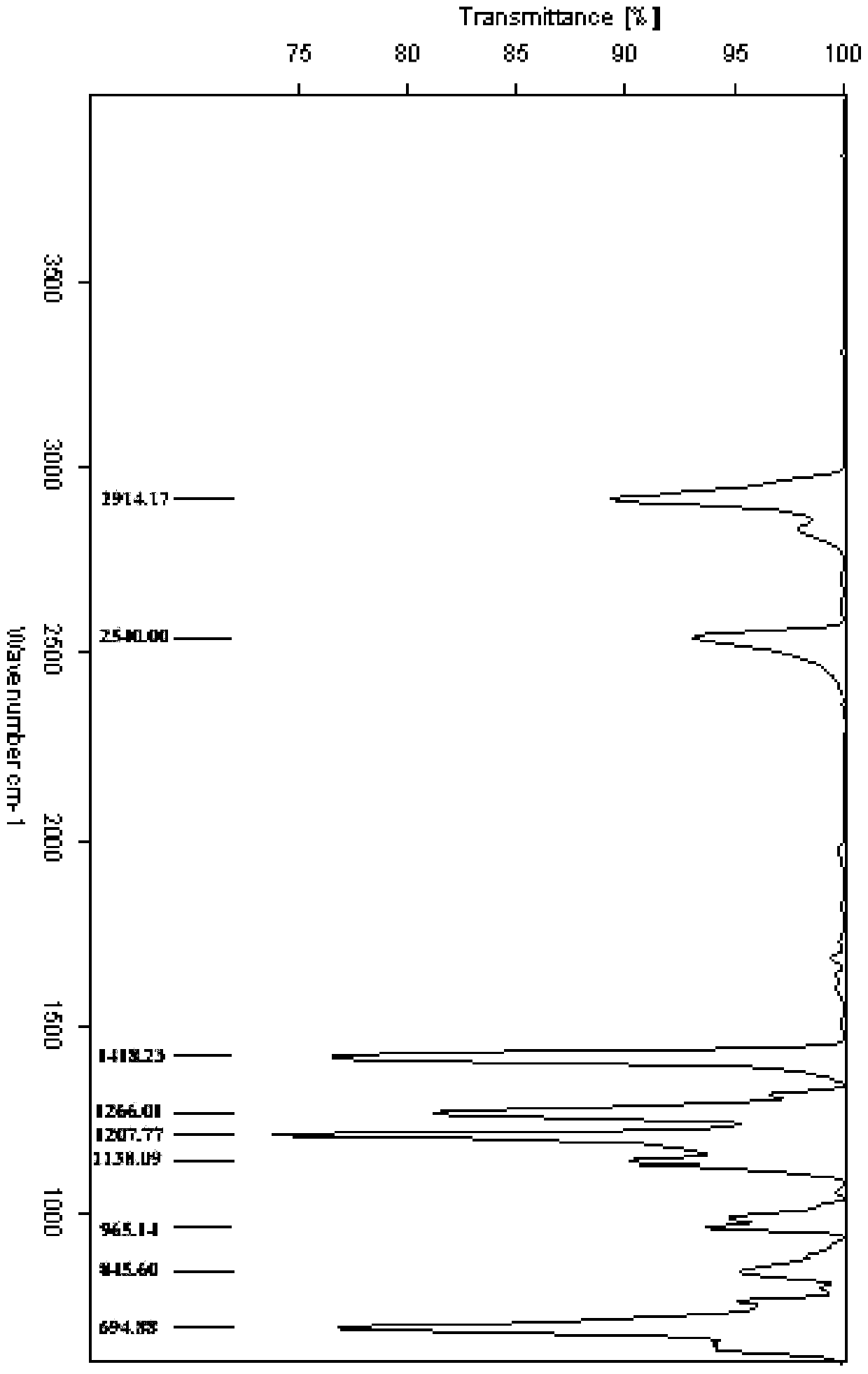

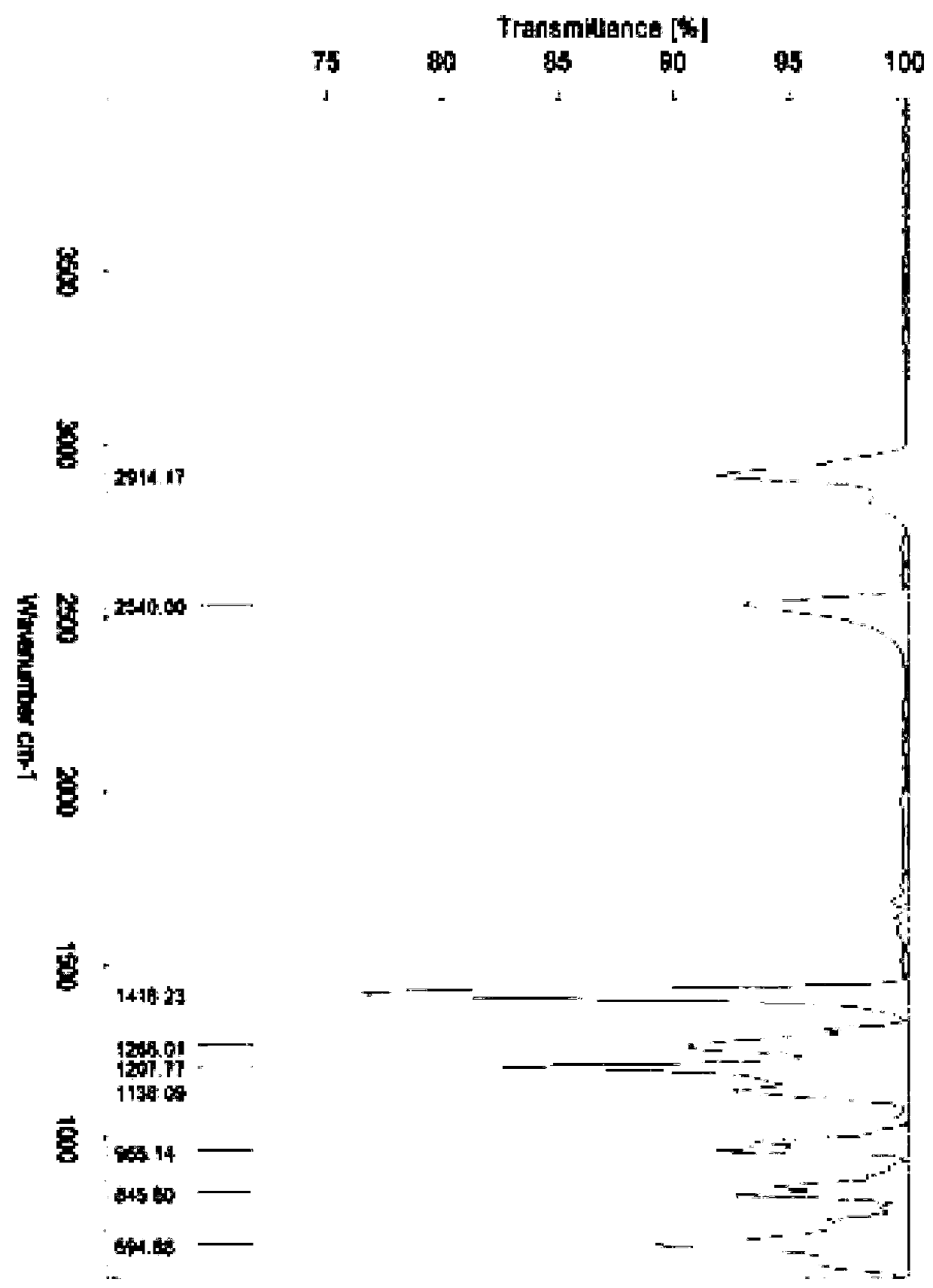

Image

Examples

Embodiment 1

[0030] Carboxyethylthiosuccinic acid: take by weighing 107.8g (1.10mol) maleic anhydride and dissolve in 300g water, heat to 90°C, add 108.16g of 3-mercaptopropionic acid with a mass fraction of 98% dropwise with a constant pressure funnel, The dropping time is controlled at 1h, after stirring evenly, add maleic anhydride and 3-mercaptopropionic acid with 10% triethylamine, react at a constant temperature of 90°C for 3h, then cool and crystallize, filter to obtain a white solid, and dry it in an oven to obtain carboxyl Ethylthiosuccinic acid, the yield is 97%;

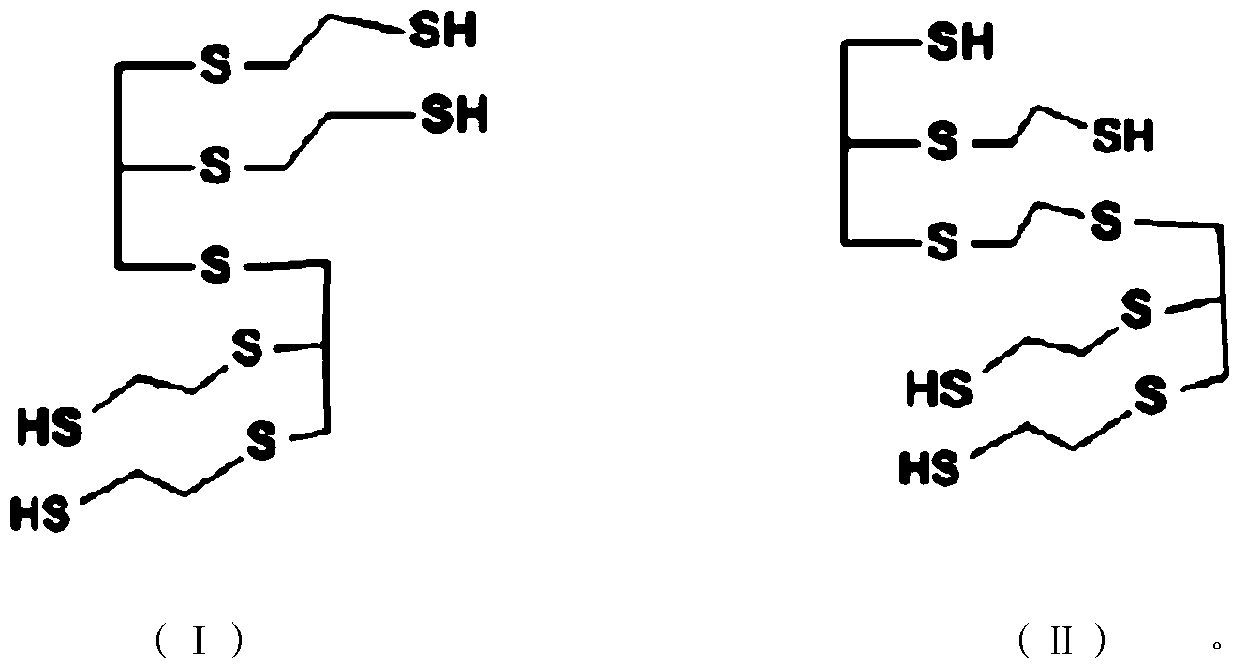

[0031] Complexing agent: Weigh 261g (1.0mol) of 2,3-dithio(2-mercapto)-1-propanethiol into a three-necked flask equipped with a stirring paddle, heat to 55°C in a water bath, and add 62g in 3 times (2.0mol) sulfur solid, reacted for 1h under stirring conditions, after the reaction was completed, cooled to room temperature to obtain a transparent liquid, filtered to obtain a liquid product, weighed, and the yield was 85...

Embodiment 2

[0034] Carboxyethylthiosuccinic acid: Weigh 102.96g (1.05mol) of maleic anhydride and dissolve it in 300g of water, heat to 90°C, add 108.16g of 98% 3-mercaptopropionic acid dropwise with a constant pressure funnel, and the dropping time Controlled at 1h, after stirring evenly, add maleic anhydride and 3-mercaptopropionic acid resin catalyst SepliteLSZ-106 with 10% of the total mass, react at a constant temperature of 90°C for 3h, then cool and crystallize, filter to obtain a white solid, and dry it in an oven to obtain Carboxyethylthiosuccinic acid, yield 96%;

[0035] Complexing agent: Weigh 261g (1.0mol) of 2,3-dithio(2-mercapto)-1-propanethiol into a three-necked flask equipped with a stirring paddle, heat to 60°C in a water bath, and add 48g in 5 times (1.5mol) sulfur solid, reacted under stirring conditions for 2h, after the reaction was completed, lowered to room temperature to obtain a transparent liquid, filtered to obtain a liquid product, weighed, and the yield was ...

Embodiment 3

[0038] Carboxyethylthiosuccinic acid: Weigh 102.96g (1.05mol) of maleic anhydride and dissolve it in 300g of water, heat to 90°C, add 108.16g of 98% 3-mercaptopropionic acid dropwise with a constant pressure funnel, and the dropping time Control it for 1 hour, after stirring evenly, add SepliteLSZ-106S with 10% of the total mass of maleic anhydride and 3-mercaptopropionic acid, react at a constant temperature of 90°C for 3 hours, then cool and crystallize, filter to obtain a white solid, and dry it in an oven to obtain carboxyethyl Thiosuccinic acid, yield 96%;

[0039] Complexing agent: Weigh 261g (1.0mol) of 2,3-dithio(2-mercapto)-1-propanethiol into a three-necked flask equipped with a stirring paddle, heat to 60°C in a water bath, and add 48g in 4 times (1.5mol) sulfur solid, reacted under stirring conditions for 3h, after the reaction was completed, lowered to room temperature to obtain a transparent liquid, filtered to obtain a liquid product, weighed, and the yield was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com