a soaping agent

The technology of a soaping agent and an activator is applied in the preparation of soap detergent compositions, detergent compositions, and detergent mixture compositions, etc., and can solve the problems of large energy consumption, lack, and reduced application performance research reports, etc., To achieve the effect of bright and pure color, easy to wash off, excellent anti-staining performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of environment-friendly soaping agent, comprises following preparation steps:

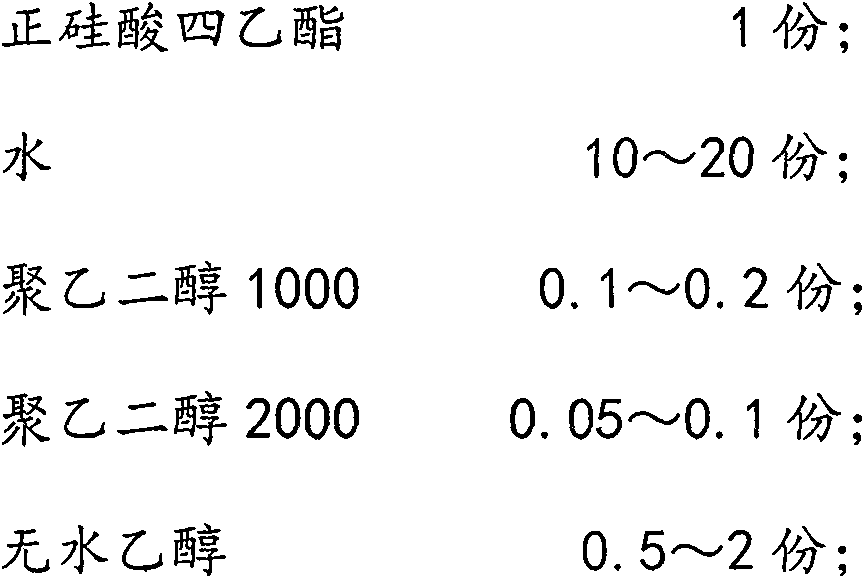

[0031] 1) Preparation of macroporous silica: prepare the following substances in parts by mass at a normal temperature of 20°C to 25°C:

[0032]

[0033] After mixing the above mass parts evenly, dry at 40°C for 5 hours, then put it into a muffle furnace and calcinate at 500°C for 1 hour;

[0034] 2), the preparation of chitosan solution: prepare the material of following mass parts:

[0035] 100 parts of 2% concentration of acetic acid solution;

[0036] 1 part of medical food grade chitosan;

[0037] The material of the above mass parts was stirred at a rate of 60 rpm for 0.5 hour;

[0038] 3), the immobilization of laccase:

[0039] Soak the macroporous silica prepared in step 1) into the chitosan solution prepared in step 2) at a normal temperature of 20°C for 10 hours, filter and dry, then immerse in the chitosan solution at a normal temperature of 20°C 5 hours in a 5% la...

Embodiment 2

[0044] A kind of environment-friendly soaping agent, comprises following preparation steps:

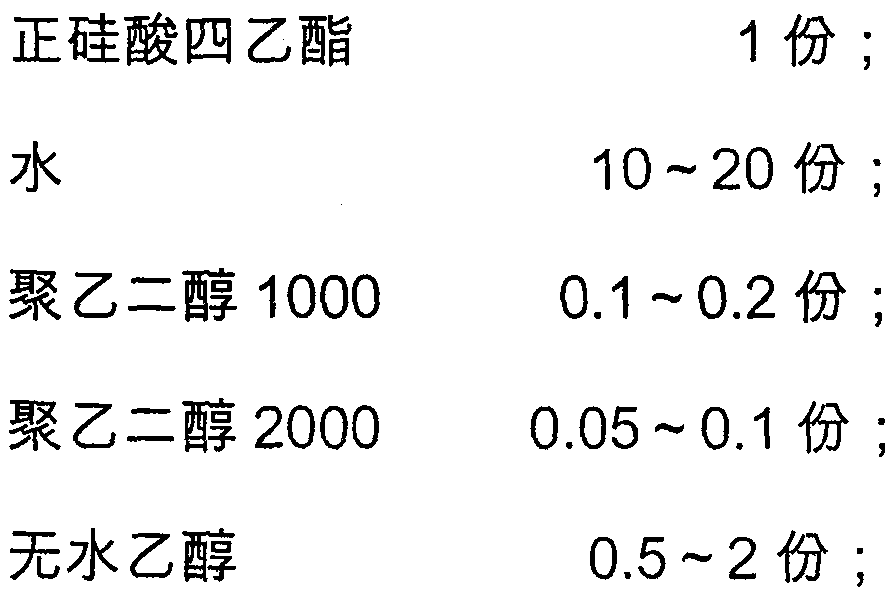

[0045] 1), preparation of macroporous silica: prepare the following substances in parts by mass at a normal temperature of 20°C to 25°C:

[0046]

[0047] After mixing the above mass parts evenly, dry at 80°C for 20 hours, and then put it into a muffle furnace for calcination at 700°C for 3 hours;

[0048] 2), the preparation of chitosan solution: prepare the material of following mass parts:

[0049] 100 parts of 2% concentration of acetic acid solution;

[0050] 2.5 parts of medical food grade chitosan;

[0051] Stir the above mass parts at a rate of 150 rpm for 1 hour;

[0052] 3), the immobilization of laccase:

[0053] Soak the macroporous silica prepared in step 1) into the chitosan solution prepared in step 2) at a normal temperature of 30°C for 24 hours, filter and dry, then immerse in the chitosan solution at a normal temperature of 30°C 12 hours in a 10% laccase stoc...

Embodiment 3

[0058] A kind of environment-friendly soaping agent, comprises following preparation steps:

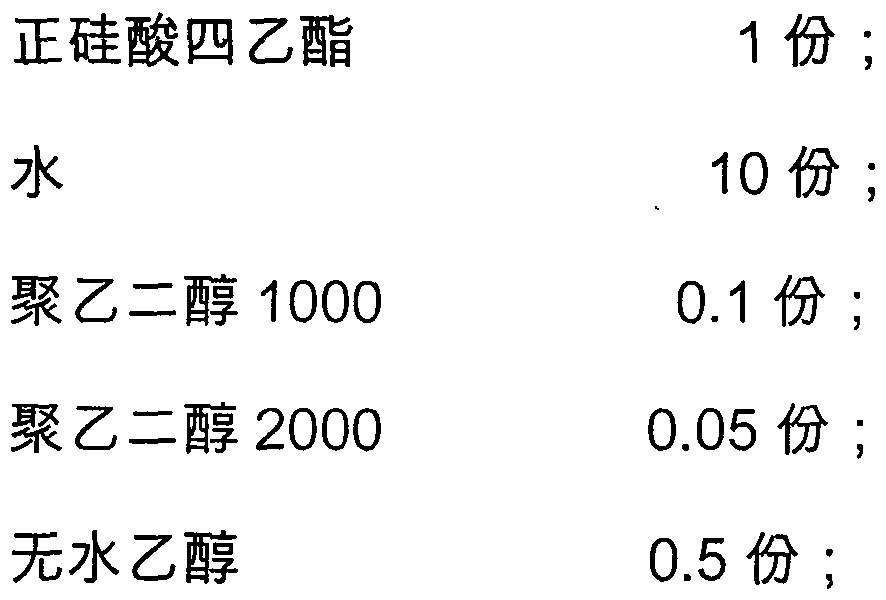

[0059] 1) Preparation of macroporous silica: prepare the following substances in parts by mass at a normal temperature of 20°C to 25°C:

[0060]

[0061] After mixing the above-mentioned substances in parts by mass evenly, dry at 60°C for 13 hours, and then put them into a muffle furnace for calcination at 600°C for 2 hours;

[0062] 2), the preparation of chitosan solution: prepare the material of following mass parts:

[0063] 100 parts of 2% concentration of acetic acid solution;

[0064] 1.7 parts of medical food grade chitosan;

[0065] The material of the above mass parts was stirred at a rate of 100 rpm for 0.75 hours;

[0066] 3), the immobilization of laccase:

[0067] Soak the macroporous silica prepared in step 1) into the chitosan solution prepared in step 2) at normal temperature of 20-30°C for 10-24 hours, filter and dry, At normal temperature, immerse in 5-10% l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com