PU (polyurethane) golden oil capable of preventing dyeing and discoloration of veneers and preparation method of PU golden oil

An anti-staining and veneer technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve problems such as performance defects, color change, veneer yellowing, etc., to achieve good weather resistance and chemical resistance, improve weather resistance, The effect of fast evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

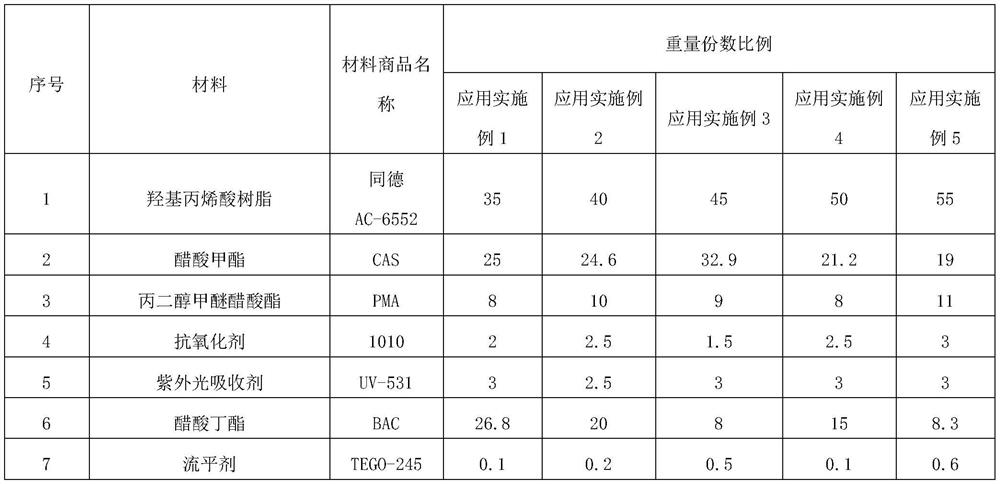

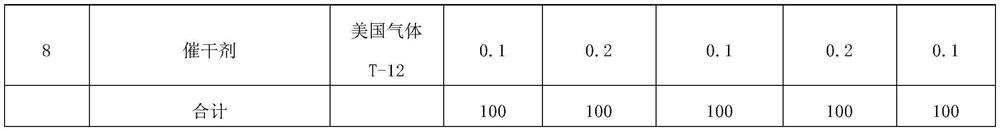

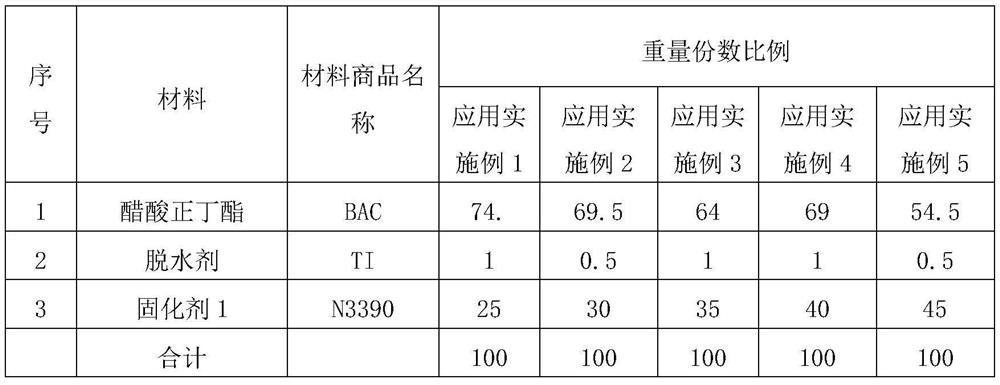

Examples

Embodiment 1

[0032] The invention discloses an anti-staining veneer discoloration PU gold oil, which includes a group A and a B component with a mass ratio of 2:1; the first component includes the following components in parts by mass: 55 parts of hydroxy acrylic resin, 1.5 parts of antioxidants parts, 2 parts of UV absorber, 10 parts of ether ester solvent, 30 parts of ester solvent, 0.1 part of defoamer, 0.1 part of leveling agent, 0.15 part of drier; component B includes the following components by mass : 55 parts of n-butyl acetate, 1 part of dehydrating agent, 35 parts of HDI curing agent.

[0033] In this embodiment, in the first component, the fineness of the hydroxy acrylic resin is 3-10 microns, the viscosity is 2500-3500 CPS, and the hydroxyl value content is 2-3; the ester solvent is n-butyl acetate, and the ether ester solvent is Propylene Glycol Methyl Ether Acetate (PMA); Antioxidant is Ciba 1130 Antioxidant; UV Absorber is UV-2 of Disparon; Leveling Agent is Substrate Wettin...

Embodiment 2

[0036] The invention discloses an anti-staining veneer discoloration PU gold oil, which includes a group A and a B component with a mass ratio of 2:1; the first component includes the following components in parts by mass: 45 parts of hydroxy acrylic resin, 0.5 parts of antioxidants parts, 3 parts of UV absorber, 8 parts of ether ester solvent, 30 parts of ester solvent, 0.5 part of defoamer, 0.075 part of leveling agent, 0.1 part of drier; component B includes the following components by mass : 75 parts of n-butyl acetate, 0.75 parts of dehydrating agent, 25 parts of HDI curing agent.

[0037] In this embodiment, in the first component, the fineness of the hydroxy acrylic resin is 3-10 microns, the viscosity is 2500-3500 CPS, and the hydroxyl value content is 2-3; the ester solvent is ethyl acetate, and the ether ester solvent is propylene glycol Methyl ether acetate (PMA); Antioxidant is Antioxidant Disparon 1010; Ultraviolet light absorber is Disparon's UV-531; Leveling age...

Embodiment 3

[0040] The invention discloses an anti-staining veneer discoloration PU gold oil, which includes a group A and a B component with a mass ratio of 2:1; the first component includes the following components in parts by mass: 35 parts of hydroxy acrylic resin, 2 parts of antioxidants parts, 2.5 parts of UV absorber, 5 parts of ether ester solvent, 40 parts of ester solvent, 0.3 part of defoamer, 0.05 part of leveling agent, 0.2 part of drier; component B includes the following components by mass : 65 parts of n-butyl acetate, 0.5 parts of dehydrating agent, 45 parts of HDI curing agent.

[0041] In this embodiment, in the first component, the fineness of the hydroxy acrylic resin is 3-10 microns, the viscosity is 2500-3500 CPS, and the hydroxyl value content is 2-3; the ester solvents are n-butyl acetate and ethyl acetate, ether The ester solvent is propylene glycol methyl ether acetate (PMA); the antioxidants are the antioxidants Ciba 1130 and Disbalon 1010; the ultraviolet ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com