Low-temperature soaping agent for cellulose reactive dye

A low-temperature soap and surfactant technology, which is applied in the field of textile material printing and dyeing, can solve the problems of difficult penetration into the fiber, lack of universal adaptability, and high requirements for experimental operations, so as to achieve enhanced wetting and penetration performance and strong tolerance , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation process of low temperature soaping agent of the present invention is as follows:

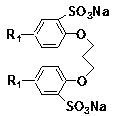

[0041] Add 1-20 parts by weight of sodium dodecyl diphenyl ether disulfonate, 5-15 parts by weight of anionic surfactant AOT, 0.1-0.5 parts by weight of defoamer, 0.1- 5 parts by weight, 0.2-2 parts by weight of sodium polyacrylate, 1-10 parts by weight of polyvinylpyrrolidone, the balance of deionization, stirring evenly, and discharging.

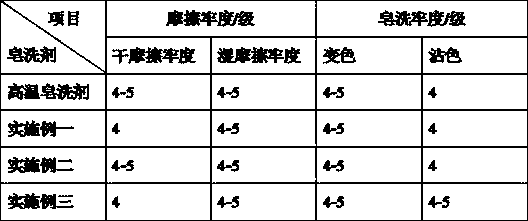

Embodiment 1

[0043] A kind of preparation method of low temperature soaping agent is as follows:

[0044] Add 7 parts by weight of sodium didodecyl diphenyl ether disulfonate, 5 parts by weight of anionic surfactant AOT, 0.2 parts by weight of polyether silicone defoamer, 1 part by weight of β-cyclodextrin in the reaction kettle, 1.8 parts by weight of sodium polyacrylate, 2 parts by weight of polyvinylpyrrolidone, the balance of deionization, stirring evenly, and discharging.

Embodiment 2

[0046] A kind of preparation method of low temperature soaping agent is as follows:

[0047] Add 3 parts by weight of sodium didodecyl diphenyl ether disulfonate, 6 parts by weight of anionic surfactant AOT, 0.3 parts by weight of polyether silicone defoamer, and 0.8 parts by weight of β-cyclodextrin in the reaction kettle , 1.5 parts by weight of sodium polyacrylate, 1-part by weight of polyvinylpyrrolidone, the balance of deionization, stirring evenly, and discharging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com