A low modulus waterborne polyurethane material

A water-based polyurethane, low-modulus technology, applied in the field of polyurethane materials, can solve the problems of the adverse effect of product elongation at break, lack of strength and elongation at break, glove feel hard, and achieve soft feel, prevent back-sticking, Easy to wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

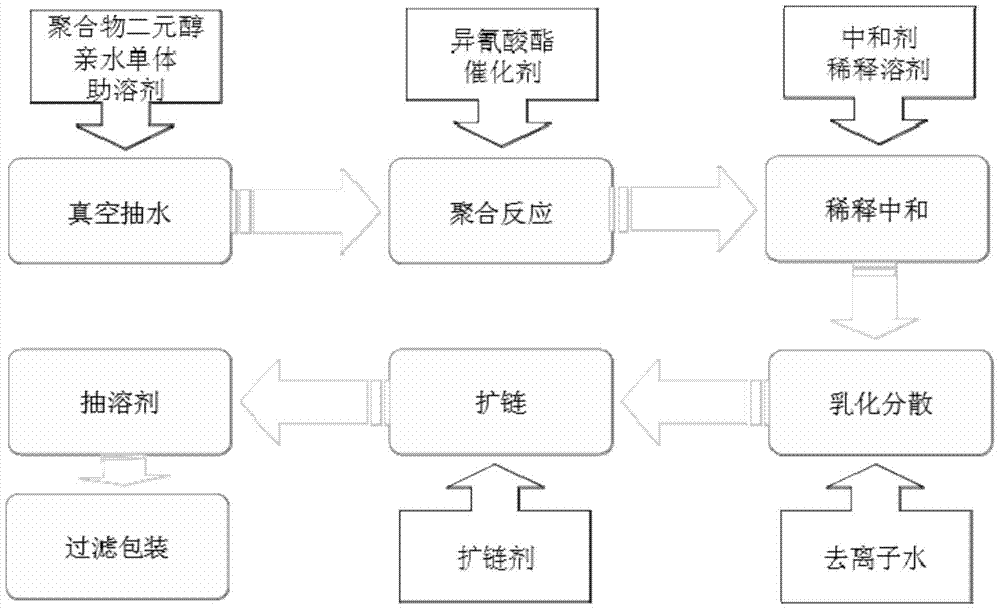

[0035] (1) Preparation of polyurethane dispersion (by the material of mass parts shown in Table 1)

[0036] Step 1, put polymer diol (polytetrahydrofuran diol 3000, polypropylene glycol 2000), hydrophilic monomer dimethylolpropionic acid (DMPA) and cosolvent N-methylpyrrolidone (NMP) into the reaction kettle , Vacuum dehydration above 100℃ for more than 1h;

[0037] Step 2, the temperature of the reactor is lowered to below 90°C, adding toluene diisocyanate (TDI), adding catalyst organotin, raising the temperature, and reacting;

[0038] Step 3, cooling down to below 55°C, adding neutralizing agent triethylamine and diluting solvent acetone;

[0039] Step 4: Place in a stirring line with a linear speed of 8m / s, add deionized water, add chain extender ethylenediamine, continue to stir for 10min, heat up to 60°C, vacuum the solvent for more than 1h, cool, filter, pack, and obtain Polyurethane dispersions, that is, low modulus waterborne polyurethane materials (such as figure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com