Thermoplastic acrylic building exterior wall coating and preparation method thereof

A technology of thermoplastic acrylic and building exterior walls, which is applied in the direction of coating, etc., can solve the problems of difficult three-dimensional network cross-linking structure, brittle coating film at high temperature, poor solvent release, etc., and achieve the improvement of brittleness at low temperature and high temperature Viscous, good resin fluidity, low surface tension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

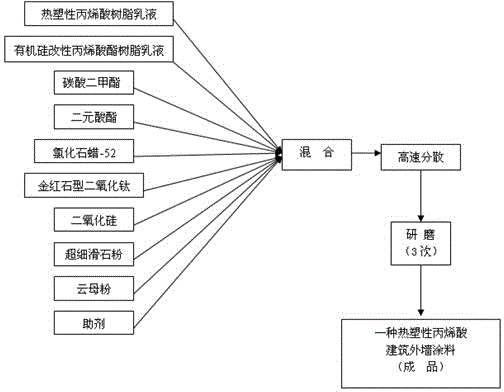

[0060] First, 90 kg of architectural thermoplastic acrylic resin emulsion, 30 kg of silicone modified acrylic resin emulsion, 30 kg of dimethyl carbonate, 5 kg of dibasic acid ester, 1 kg of chlorinated paraffin-52, 25 kg of rutile titanium dioxide, 5 kg of silicon oxide, 5 kg of superfine talc powder, 5 kg of mica powder, and 6 kg of additives were uniformly mixed in a high-speed disperser in proportion to 15 minutes; the mixed materials were ground three times by a sand mill, each time about 1 o'clock. When the fineness reaches below 25 microns, it can be weighed and packaged as a finished product.

Embodiment 2

[0062]First, 120 kg of building thermoplastic acrylic resin emulsion, 40 kg of silicone modified acrylic resin emulsion, 50 kg of dimethyl carbonate, 7 kg of dibasic acid ester, 2 kg of chlorinated paraffin-52, 40 kg of rutile titanium dioxide, 7 kg of silicon oxide, 7 kg of superfine talc powder, 7 kg of mica powder, and 8 kg of additives were uniformly mixed in a high-speed disperser in proportion for 15 minutes; the mixed materials were ground three times by a sand mill, each time about 1 o'clock. When the fineness reaches below 25 microns, it can be weighed and packaged as a finished product.

Embodiment 3

[0064] First, 150 kg of building thermoplastic acrylic resin emulsion, 50 kg of silicone modified acrylic resin emulsion, 70 kg of dimethyl carbonate, 8 kg of dibasic acid ester, 3 kg of chlorinated paraffin-52, 50 kg of rutile titanium dioxide, 8 kg of silicon oxide, 8 kg of superfine talc powder, 8 kg of mica powder, and 9 kg of additives were uniformly mixed in a high-speed disperser in proportion to 15 minutes; the mixed materials were ground three times by a sand mill, each time about 1 o'clock. When the fineness reaches below 25 microns, it can be weighed and packaged as a finished product.

[0065] The thermoplastic acrylic building exterior wall paint of the present invention is used in high-grade building exterior wall decoration, house surface, steel structure facility surface, and outdoor large-scale sculpture coating, all play good adhesion, strong chemical resistance, acid resistance Alkalinity, water resistance, good solvent resistance, temperature change resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com