Laundry detergent

A technology of laundry detergent and sodium carboxymethyl cellulose, applied in the field of laundry detergent, can solve the problems of poor anti-staining effect of dyes or pigments, poor emulsifying ability of oil stains, darkening of clothes color, etc., and achieves performance stability and detergency. Strong and prevent stains from sticking back

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

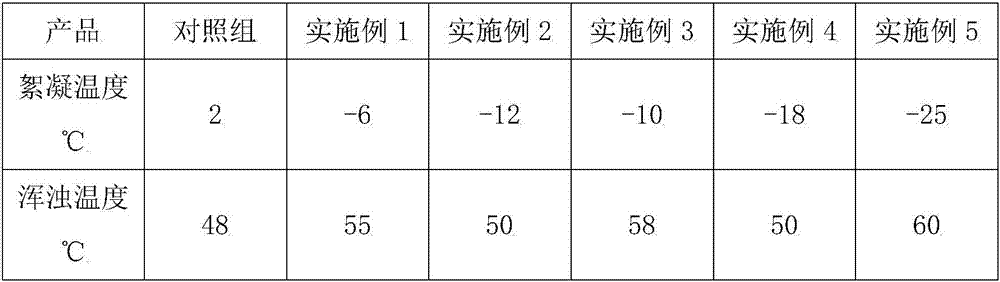

Examples

Embodiment 1

[0022] A laundry detergent, comprising the following components in parts by weight:

[0023] 20 parts of fatty alcohol polyoxyethylene ether, 15 parts of sodium lauroyl glutamate, 2 parts of diethanolamide cocoate, 6 parts of polyoxyethylene lauryl ether, 3 parts of polyoxyethylene stearate, anti-redeposition agent 20 parts, anti-condensation agent 2 parts, plant essential oil 1 part, preservative 0.1 part, deionized water 70 parts.

[0024] The anti-redeposition agent sodium cellulose and sodium polyacrylate are added in a mass ratio of 10:1.

[0025] The anticondensation agent is ethanol; the plant essential oil is rose essential oil; the preservative is sodium benzoate.

Embodiment 2

[0027] A laundry detergent, comprising the following components in parts by weight:

[0028] 30 parts of fatty alcohol polyoxyethylene ether, 10 parts of sodium lauroyl glutamate, 5 parts of diethanolamide cocoate, 2 parts of polyoxyethylene lauryl ether, 7 parts of polyoxyethylene stearate, anti-redeposition agent 10 parts, anti-condensation agent 10 parts, plant essential oil 0.2 parts, preservative 0.3 parts, deionized water 40 parts.

[0029] The mass addition ratio of sodium cellulose and sodium polyacrylate in the anti-redeposition agent is 2:1.

[0030] The anticondensation agent is glycerol; the plant essential oil is sandalwood essential oil; the preservative is sodium benzoate.

Embodiment 3

[0032] A laundry detergent, comprising the following components in parts by weight:

[0033] 25 parts of fatty alcohol polyoxyethylene ether, 13 parts of sodium lauroyl glutamate, 4 parts of diethanolamide cocoate, 3 parts of polyoxyethylene lauryl ether, 5 parts of polyoxyethylene stearate, anti-redeposition agent 17 parts, anticondensation agent 4 parts, plant essential oil 0.7 part, preservative 0.2 part, deionized water 50 parts.

[0034] The mass addition ratio of sodium cellulose and sodium polyacrylate in the anti-redeposition agent is 6:1.

[0035] The anticondensation agent is ethanol; the plant essential oil is peppermint essential oil; the preservative is sodium benzoate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com