Refining degreaser based on modified nano argil and preparation method of refining degreaser

A technology of nano-clay and degreasing agent, applied in the preparation of detergent mixture composition, chemical equipment and method, surface active detergent composition, etc., can solve the problem that impurities cannot be completely removed and back stained fabrics and machines, etc. Achieve good biodegradability, improve refining degreasing effect, low viscosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

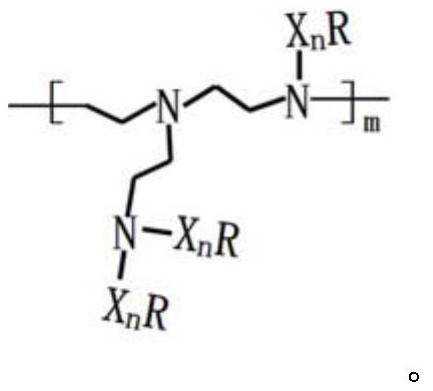

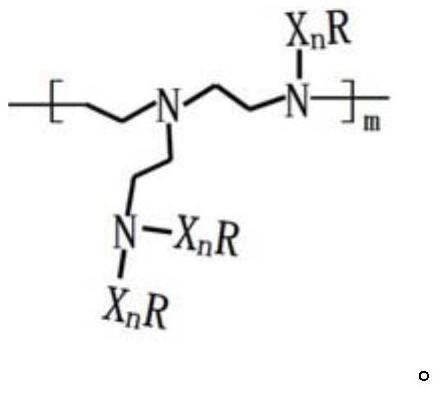

Image

Examples

Embodiment 1

[0032] Preparation of modified nano clay:

[0033] 1. Add 500kg of nano-clay suspension dispersion into the reaction kettle, add 0.05mol / L hydrochloric acid, and stir and react at 60°C and 300r / min for 1.5h. Heat up to 75°C, add 50kg of Lupasol, stir for 4 hours, cool down to room temperature, and then neutralize with 10% sodium hydroxide solution to pH 6-8.

[0034] 2. The solution obtained in step 1 is dispersed by ultrasonic: the ultrasonic power is 800W, and the ultrasonic time is 30min, to obtain the modified nano clay solution.

[0035] Preparation of modified nano clay refining degreaser:

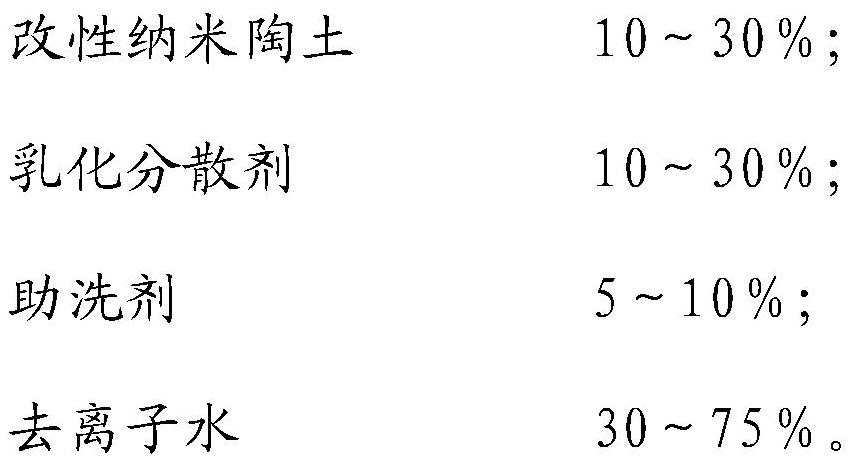

[0036] Comprising the following raw materials in parts by weight:

[0037]

[0038] Its preparation process is as follows:

[0039] a: Treat the modified nanoclay solution in a homogenizer for 120 minutes;

[0040] b: The liquid matrix forming the emulsified dispersant and builder system is fully mixed to form a uniform liquid phase by imparting shear and stirring the liquid for...

Embodiment 2

[0043] Preparation of modified nanoclay: prepared according to Example 1.

[0044] Preparation of modified nano clay refining degreaser:

[0045] Comprising the following raw materials in parts by weight:

[0046]

[0047] Its preparation process is as follows:

[0048] a: Treat the modified nano clay solution in a homogenizer for 60 minutes;

[0049] b: The liquid matrix forming the emulsified dispersant and builder system is fully mixed to form a uniform liquid phase by imparting shear and stirring the liquid for 30 minutes at 80°C;

[0050] c: Cool to 50°C under continuous stirring, then add the modified nanoclay obtained in step a to the mixture obtained in step b, stir for 30 minutes to form a uniform dispersion, and then process it in a homogenizer for 60 minutes to obtain the described Refined degreaser B based on modified nanoclay.

Embodiment 3

[0052] Preparation of modified nanoclay: prepared according to Example 1.

[0053] Preparation of modified nano clay refining degreaser:

[0054] Comprising the following raw materials in parts by weight:

[0055]

[0056] Its preparation process is as follows:

[0057] a: Treat the modified nano clay solution in a homogenizer for 90 minutes;

[0058] b: The liquid matrix forming the emulsified dispersant and builder system is fully mixed to form a uniform liquid phase by imparting shear and stirring the liquid for 50 minutes at 60°C;

[0059] c: Cool to 40°C under continuous stirring, then add the modified nanoclay obtained in step a to the mixture obtained in step b, stir for 50 minutes to form a uniform dispersion, and then process it in a homogenizer for 120 minutes to obtain the described Refining degreaser C based on modified nanoclay.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com