Heat melting high-wear-resistant anti-pollution yellow traffic marking material and preparation method thereof

A traffic marking and high wear-resistant technology, applied in the traffic field, can solve the problems of affecting the visual effect of markings, increasing the hidden danger of traffic accidents, and failing to reach the friction coefficient, etc., achieving good reflective properties, good adhesive adhesion, and not easy to wear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] In this embodiment, a hot-melt high wear-resistant anti-pollution yellow traffic marking material includes the following components in parts by weight: 16.5 parts of petroleum resin, 6 parts of modified rosin resin, and 0.36 parts of di-n-butyl phthalate , 9 parts of glass microspheres, 6.9 parts of ethylene vinyl acetate copolymer, 1.35 parts of microcrystalline paraffin, 0.55 parts of refined white mineral oil, 27 parts of quartz sand, 29.18 parts of quartz powder, and 3.16 parts of cadmium yellow.

[0024] In this embodiment, a hot-melt high wear-resistant anti-pollution yellow traffic marking material, the specific preparation method includes the following steps:

[0025] a .Add di-n-butyl phthalate and refined white mineral oil to the reaction kettle with stirring and mixing function according to the parts by weight, stir evenly, and let it stand for defoaming for later use;

[0026] b. Start the powder material mixer with high-pressure liquid spraying device, th...

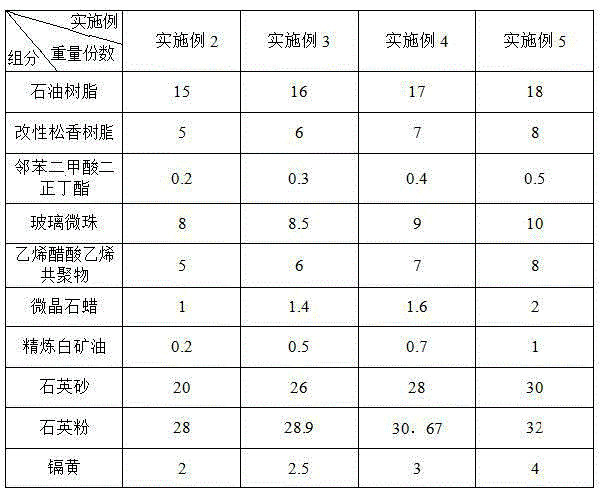

Embodiment 2~ Embodiment 5

[0031] Each component and preparation method in embodiment 2~embodiment 5 are all the same as embodiment 1, and the difference is only that the parts by weight of each component are different, specifically as shown in the following table:

[0032]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com