Method for extracting natural algicide from Acorus calamus L and algae inhibition method

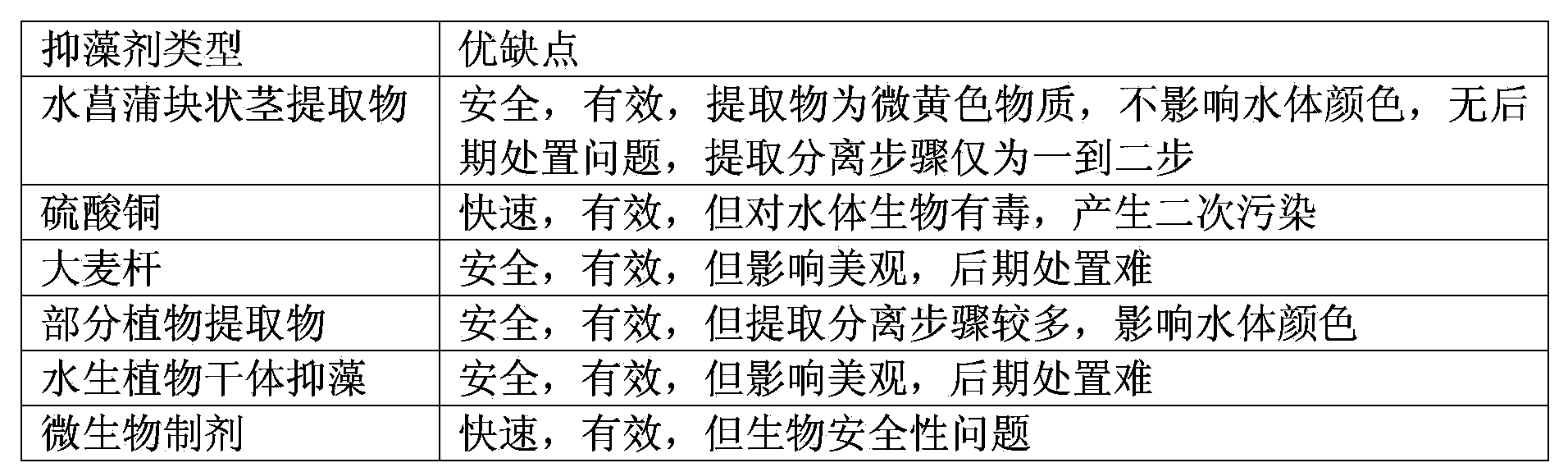

The technology of an algae inhibitor and water calamus, which is applied in the field of algae inhibitory active ingredients, can solve the problems of difficulty in separation and high cost, and achieve the effects of strong environmental affinity, low cost, and simple and easy extraction method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

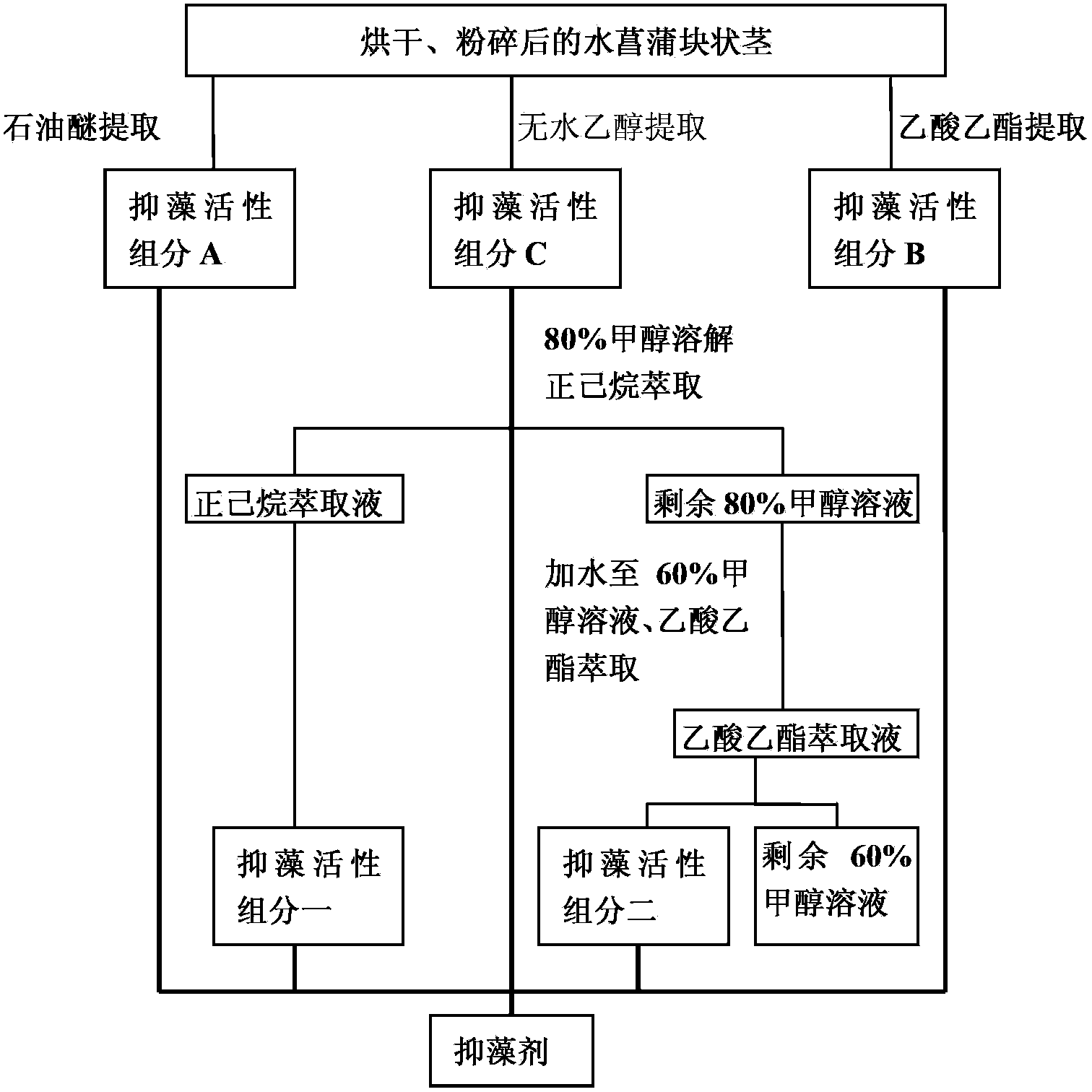

Embodiment 1

[0030] Example 1: The tuberous rhizomes of Acorus calamus were collected, dried and crushed. Weigh 50g of the crushed calamus rhizome, extract 2-3 times at 50C, 12 hours each time. Filter, combine the petroleum ether extracts, and concentrate by rotary evaporation at 35°C to obtain the algae inhibitory active component A. The active component A was subjected to acute toxicity experiments on sterile cultured single-celled Microcystis aeruginosa, colony Microcystis aeruginosa, A. algae and Anabaena algae, set several concentration gradients, set blanks and three The groups are in parallel and observed once every 24 hours for three consecutive days. The results are expressed as the inhibition rate of 96 hours. The results are as follows:

[0031] The anti-algae active ingredient A, when the mass volume concentration reaches 50mg / L (then 1 liter of water contains 50mgA), its inhibition rate of single-celled Microcystis aeruginosa reaches 90%; when the concentration reaches 100mg / L, ...

Embodiment 2

[0032] Example 2: The tuberous rhizomes of Acorus calamus were collected, dried and crushed. Weigh 50g of crushed calamus rhizome, extract 2-3 times at 50 degrees, 12 hours each time. After filtration, the ethyl acetate extracts were combined, and concentrated by rotary evaporation at 35° C. to obtain the algal inhibitory active component B.

[0033] The active ingredient B was subjected to acute toxicity experiments on sterilely cultured single-celled Microcystis aeruginosa, colony Microcystis aeruginosa, A. algae and Anabaena algae, set several concentration gradients, set blanks and three The groups are in parallel and observed once every 24 hours for three consecutive days. The results are expressed as the inhibition rate of 96 hours. The results are as follows:

[0034] Anti-algae active ingredient B, when the concentration reaches 50mg / L, its inhibition rate on single-celled Microcystis aeruginosa reaches 91%; when the concentration reaches 100mg / L, its inhibition rate on po...

Embodiment 3

[0035] Example 3: The tuberous rhizomes of Acorus calamus were collected, dried and crushed. Weigh 50g of crushed calamus rhizome, extract 2-3 times at 50 degrees, 12 hours each time. Filter, combine the absolute ethanol extracts, and concentrate by rotary evaporation at 35°C to obtain the algal inhibitory active component C.

[0036] The active ingredient C was subjected to acute toxicity experiments on sterilely cultured single-celled Microcystis aeruginosa, colony Microcystis aeruginosa, A. algae and Anabaena algae, set several concentration gradients, set blanks and three The groups are in parallel and observed once every 24 hours for three consecutive days. The results are expressed as the inhibition rate of 96 hours. The results are as follows:

[0037] Anti-algae active ingredient C, when the concentration reaches 50mg / L, its inhibition rate on single cell Microcystis aeruginosa reaches 95%; when the concentration reaches 100mg / L, its inhibition rate on population Microcyst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com