Plastic ink for solvent-free adhesive compounding and preparation method thereof

A solvent-free and ink-free technology, applied in the field of printing ink, can solve the problems of affecting the central nervous system of the brain, poor compatibility effect, human health hazards, etc., and achieve the effects of being difficult to degrade, ensuring product quality, and saving use costs.

Active Publication Date: 2016-08-03

HUANGSHAN SHINING INK TECH

View PDF5 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Fourth, the miscibility between ester alcohol solvents and traditional plastic ink binders is not good, so this type of ink contains a large amount of benzophenone solvents, which have toxic and pungent odors, and are easy to pollute the air during use. Inhalation affects the central nervous system of the brain and causes great harm to human health

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

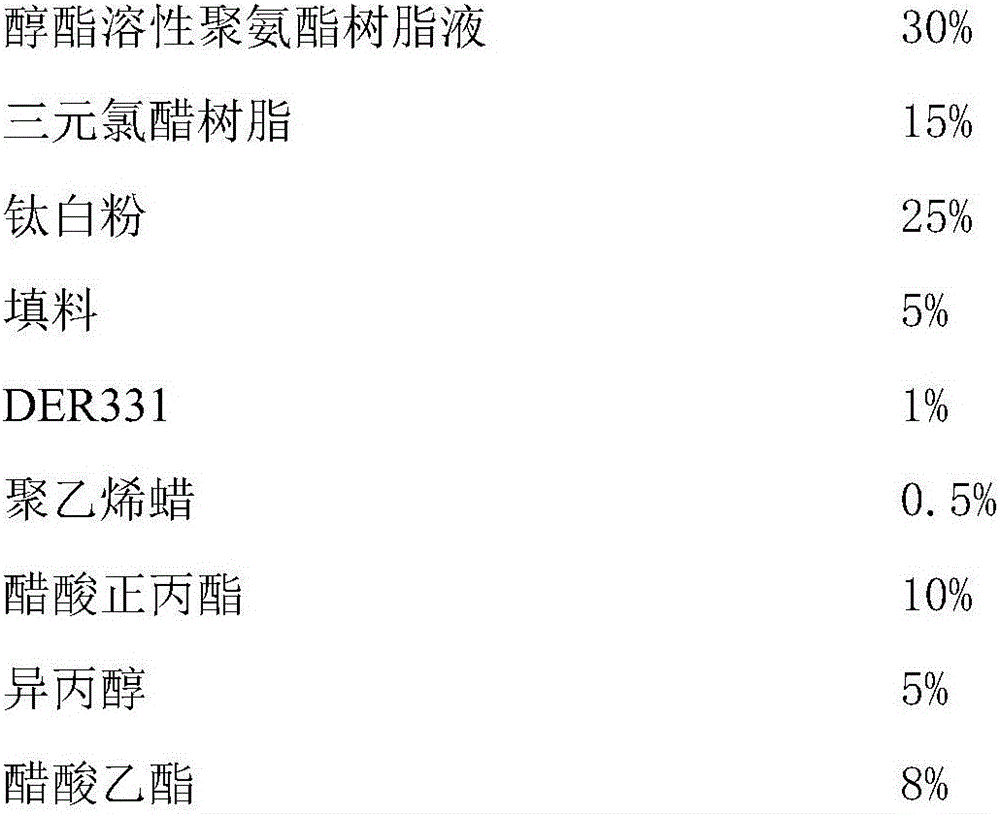

Embodiment 1

[0028]

[0029]

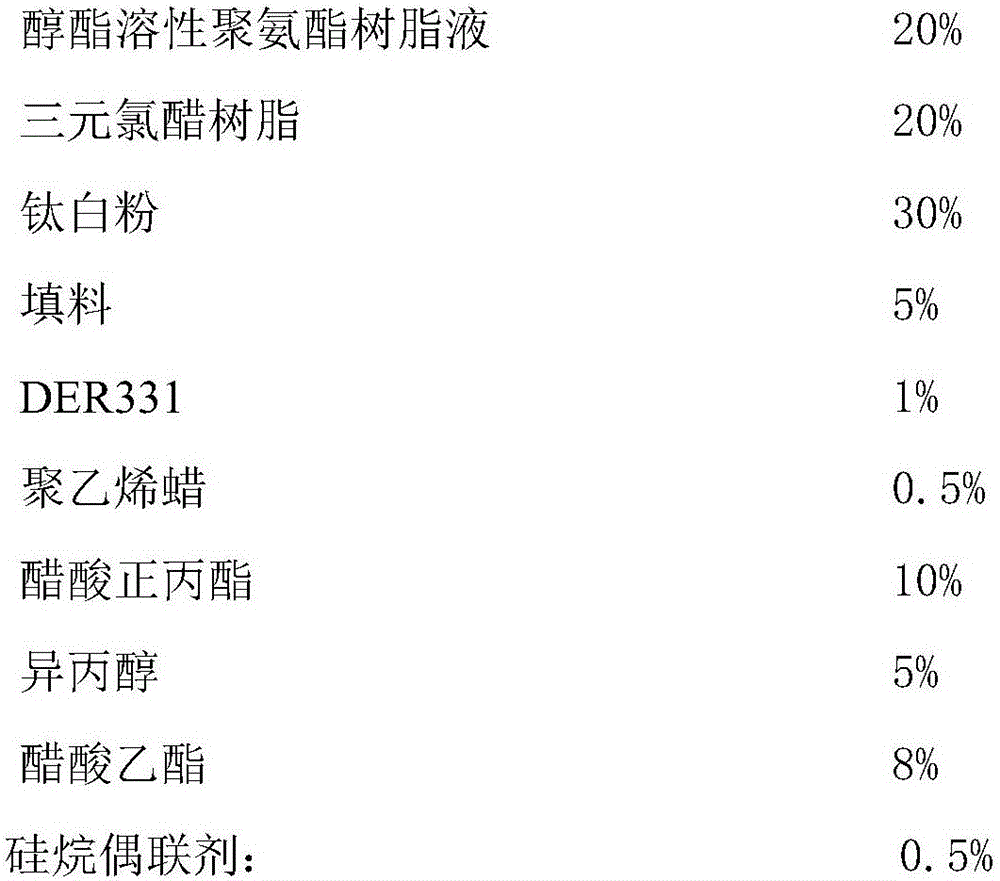

Embodiment 2

[0031]

Embodiment 3

[0033]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides ink special for polyurethane-type solvent-free adhesive compounding. The ink is prepared from ink main body connecting materials, titanium dioxide, packing, polyethylene wax, an alcohol ester solvent and a silane coupling agent; the ink main body connecting materials are composed of alcohol-ester-soluble polyurethane resin liquid and ternary vinyl chloride-vinyl acetate resin, and the ink further contains a certain amount of polyepoxide resin liquid. In addition, the invention provides a method for preparing the ink. According to the ink, the adverse effect generated by the ink and an solvent-free adhesive during solvent-free adhesive compounding of a printed product can be relieved and avoided, and the problems that a compounded product is dark, and white dots are generated on the compounded product can be solved; meanwhile, volatilization of the organic solvent can be avoided, and therefore the environmental protection requirement is met while the using cost is reduced; in addition, the ink does not generate color changes at the high temperature.

Description

technical field [0001] The invention belongs to the field of printing inks, and relates to a plastic ink suitable for solvent-free adhesive compounding and a preparation method thereof, and more particularly relates to a solvent-free ink that uses alcohol ester polyurethane resin and ternary vinyl chloride resin as ink main binders. Glue compounded plastic ink and preparation method thereof. Background technique [0002] At present, the lamination of food flexible packaging enterprises in the domestic market is still mainly dry lamination. However, with the rapid economic development and the gradual maturity of various conditions, the domestic solvent-free composite and solvent-free polyurethane adhesives are facing unprecedented opportunities. In particular, the new national standard GB / T10004-2008 "Plastic composite film for packaging, bag dry composite, extrusion composite" was introduced and implemented on August 1, 2009 (total solvent residue ≤ 5mg / m 2 , Benzene solve...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D11/102C09D11/107C09D11/03C08G18/75C08G18/66C08G18/42C08G18/10

CPCC08G18/10C08G18/4238C08G18/755C09D11/03C09D11/102C09D11/107C08G18/3234

Inventor 吴秉祯王治飞洪锋汪健吴土华罗良萍吴君方红霞

Owner HUANGSHAN SHINING INK TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com