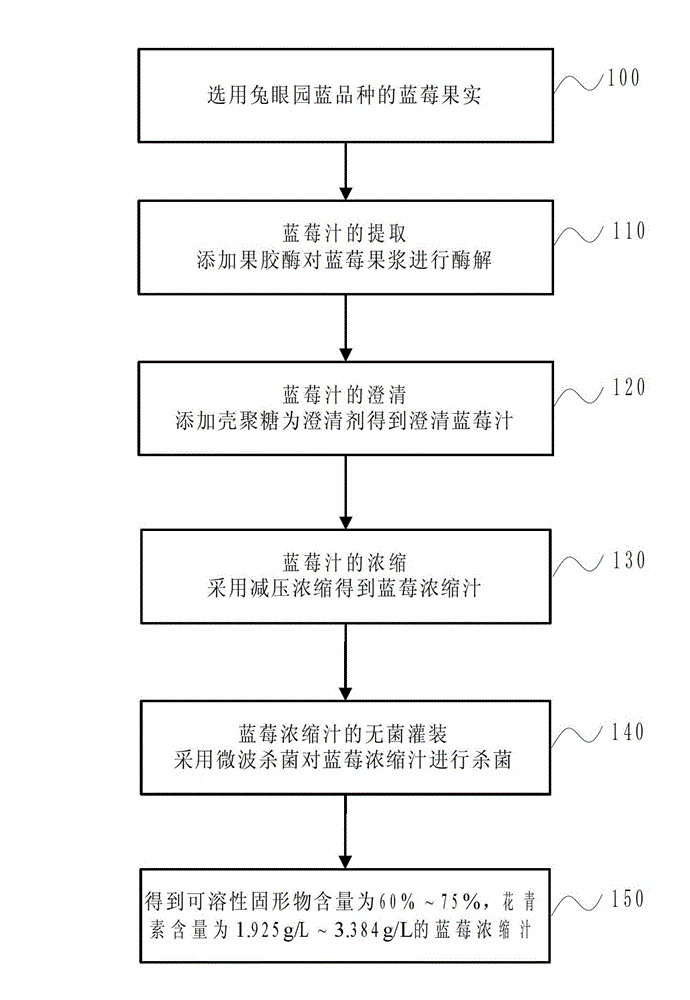

Preparation process of blueberry concentrated juice with high content of anthocyanin

A technology with high anthocyanin and preparation process, applied in the direction of food science and the like, can solve the problems of low stability of blueberry anthocyanin, poor clarification effect of blueberry juice, loss of color and aroma, etc., to protect the color and aroma, etc. Sensory quality, shortened concentration time, non-degradable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]Crush and beat the blueberry fruit of the Rabbiteye Garden blue variety, add pectinase, homogenate, and then carry out enzymatic hydrolysis; wherein, the amount of pectinase added is 0.1mg / g, the temperature of enzymatic hydrolysis is 45°C, and the enzymatic hydrolysis The time is 1 hour. After the enzymatic hydrolysis is completed, the blueberry pulp is filtered and separated into blueberry mixed juice and blueberry pomace through a centrifuge; wherein, the rotating speed of the centrifuge is 3000r / min, and the centrifugation time is 10min. After adding clarifier chitosan to the obtained blueberry mixed juice according to the addition amount of 0.15 g / L, let it stand for 12 hours, and then adopt a microfiltration membrane with a pore size of 0.2 micron to remove microorganisms by suction to obtain clarified blueberry juice. The obtained clarified blueberry juice was concentrated under reduced pressure using a rotary evaporator to obtain concentrated blueberry juice; whe...

Embodiment 2

[0039] Crush and beat the blueberry fruit of the Rabbiteye Garden blue variety, add pectinase, homogenate, and then carry out enzymatic hydrolysis; wherein, the amount of pectinase added is 1.5mg / g, the temperature of enzymatic hydrolysis is 55°C, and the enzymatic hydrolysis The time is 3 hours. After the enzymatic hydrolysis is completed, the blueberry pulp is filtered and separated into blueberry mixed juice and blueberry pomace through a centrifuge; wherein, the rotating speed of the centrifuge is 5000r / min, and the centrifugation time is 20min. The obtained blueberry mixed juice was added with clarifier chitosan according to the addition amount of 0.3 g / L, left to stand for 48 hours, and then adopting a microfiltration membrane with a pore size of 0.2 micron to remove microorganisms by suction to obtain clarified blueberry juice. The obtained clarified blueberry juice is concentrated under reduced pressure using a rotary evaporator to obtain concentrated blueberry juice; ...

Embodiment 3

[0041] Crush and beat the blueberry fruit of the Rabbiteye Garden blue variety, add pectinase, homogenate, and then carry out enzymatic hydrolysis; wherein, the amount of pectinase added is 0.6 mg / g, the temperature of enzymatic hydrolysis is 51 °C, and the enzymatic hydrolysis The time is 2.4 hours. After the enzymatic hydrolysis is completed, the blueberry pulp is filtered and separated into blueberry mixed juice and blueberry pomace through a centrifuge; wherein, the rotating speed of the centrifuge is 4000r / min, and the centrifugation time is 15min. The obtained blueberry mixed juice was added with clarifier chitosan according to the addition amount of 0.2 g / L, left to stand for 24 hours, and then adopting a microfiltration membrane with a pore size of 0.2 micron to remove microorganisms by suction to obtain clarified blueberry juice. The obtained clarified blueberry juice was concentrated under reduced pressure using a rotary evaporator to obtain concentrated blueberry ju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com