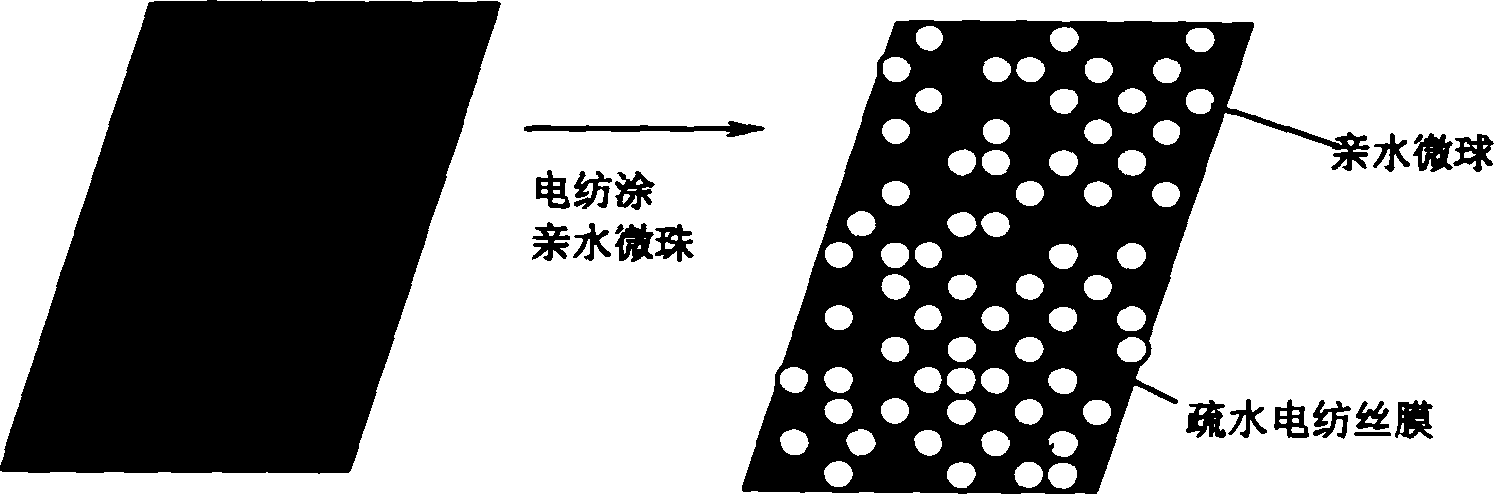

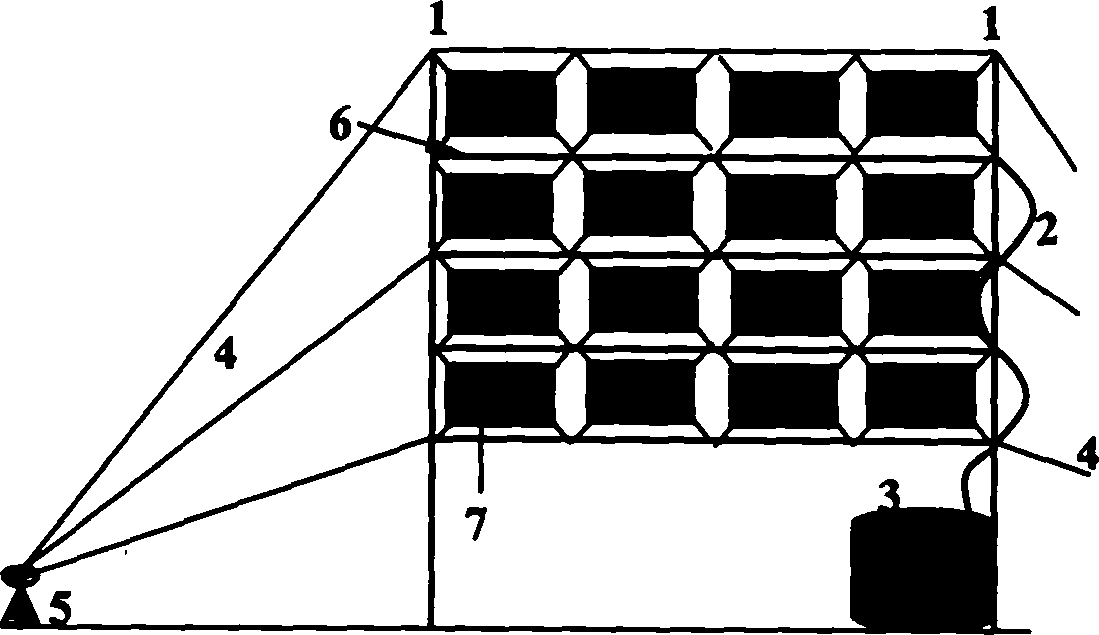

Bionic water-collecting composite electrospun film and its preparation method and use

An electrospinning and film technology, applied in water supply installations, drinking water installations, buildings, etc., can solve the problems of inability to meet the needs of water, low water collection efficiency, and high costs, and achieve improved efficiency, good outdoor stability, and extended The effect of age

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] 1) Preparation of hydrophobic polymer solution:

[0061] Slowly add 10 parts by weight of polystyrene and 2 parts by weight of silicon dioxide with an average particle size of 100 nm into 90 parts by weight of dimethyl-formamide under stirring. After fully swelling, stir at constant temperature for 2 hours until the polystyrene Ethylene was completely dissolved; then the solution was allowed to stand for 12 hours until the bubbles in the solution disappeared to obtain a hydrophobic polymer solution;

[0062] 2) Preparation of hydrophilic polymer solution:

[0063] Slowly add 15 parts by weight of polyvinyl alcohol and 3 parts by weight of titanium dioxide particles with an average particle size of 100 μm into 85 parts by weight of secondary water deionized water under stirring. After fully swelling, heat up to 80 ° C and stir at constant temperature for 2 hours Continue to stir for 2 hours at room temperature until the polyvinyl alcohol is completely dissolved; then le...

Embodiment 2

[0071] 1) Preparation of hydrophobic polymer solution:

[0072] Slowly add 10 parts by weight of polystyrene and 3 parts by weight of silicon dioxide with an average particle size of 2nm to 90 parts by weight of dimethyl-formamide under stirring. After fully swelling, stir at constant temperature for 2 hours until the polystyrene Ethylene was completely dissolved; then the solution was allowed to stand for 12 hours until the bubbles in the solution disappeared to obtain a hydrophobic polymer solution;

[0073] 2) Preparation of hydrophilic polymer solution:

[0074] Slowly add 15 parts by weight of polyvinyl alcohol and 7.5 parts by weight of titanium dioxide particles with an average particle size of 1 μm into 85 parts by weight of secondary water deionized water under stirring. After fully swelling, heat up to 80 ° C and stir at constant temperature for 2 hours Continue to stir for 2 hours at room temperature until the polyvinyl alcohol is completely dissolved; then let the...

Embodiment 3

[0082] 1) Preparation of hydrophobic polymer solution:

[0083] 10 parts by weight of polystyrene, 2.5 parts by weight of silicon dioxide with an average particle diameter of 50 nm, and 0.05 parts by weight of ultraviolet absorber 2-cyano-3,3-diphenylacrylate 2-ethylhexyl Slowly added to 90 parts by weight of dimethyl-formamide, fully swelled, stirred at constant temperature for 2 hours until the polystyrene was completely dissolved; then left the solution for 12 hours, until the bubbles in the solution disappeared, and obtained a hydrophobic polymer solution;

[0084] 2) Preparation of hydrophilic polymer solution:

[0085] Slowly add 15 parts by weight of polyvinyl alcohol and 1.5 parts by weight of titanium dioxide particles with an average particle size of 50 μm into 85 parts by weight of secondary water deionized water under stirring. After fully swelling, heat up to 80 ° C and stir at constant temperature for 2 hours Continue to stir for 2 hours at room temperature unt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com