Automatic marking machine for micro-engraving invisible mark in inner progressive resin lens

A resin lens, invisible technology, used in welding equipment, laser welding equipment, metal processing equipment and other directions, can solve the problems of polluted working environment, deep marking depth, faded marking, etc., to achieve a high degree of automation, high efficiency, marking fast speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments. The following examples are intended to illustrate the present invention, but not to limit the scope of the present invention.

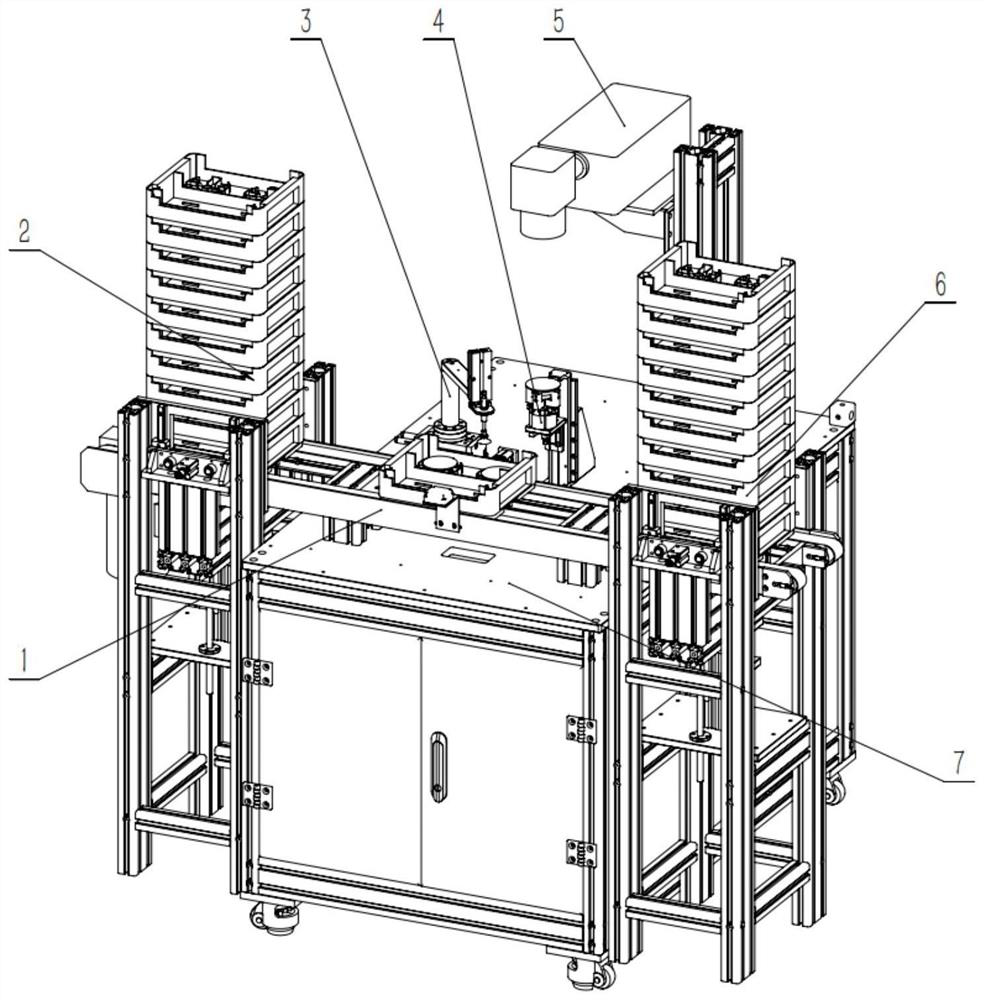

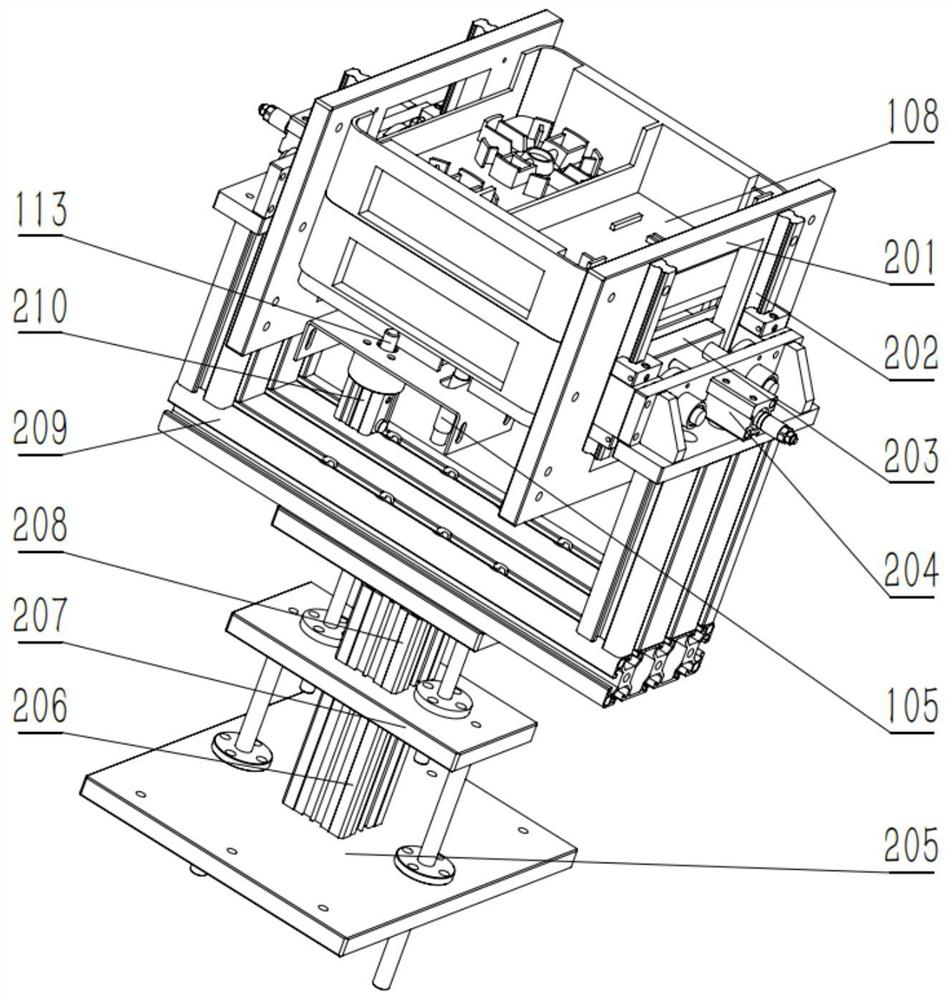

[0043] see Figure 1 to Figure 6 , an automatic marking machine for inner engraving invisible marks of inner progressive resin lenses described in a preferred embodiment of the present invention consists of a conveyor belt 1, an automatic receiving system 2, a manipulator 3, a lifting and clamping mechanism 4, a marking system 5, It is composed of automatic feeding system 6 and workbench 7.

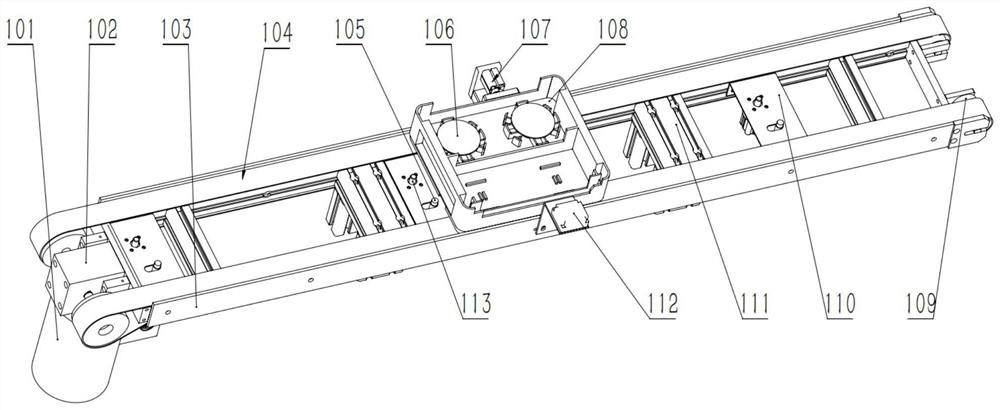

[0044] The conveyor belt 1 includes a motor 101, a reducer 102, a baffle 103, a belt 104, a proximity switch 105, a resin lens 106, a positioning cylinder 107, a material box 108, a tensioning wheel 109, a cylinder mounting frame 110, a bracket 111, and barcode scanning. device 112 and ejector rod 113 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com