Circuit board detection device and test system

A technology for testing equipment and circuit boards, which can be used in printed circuit testing, electronic circuit testing, etc., and can solve the problems of low detection efficiency of FPC flexible boards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

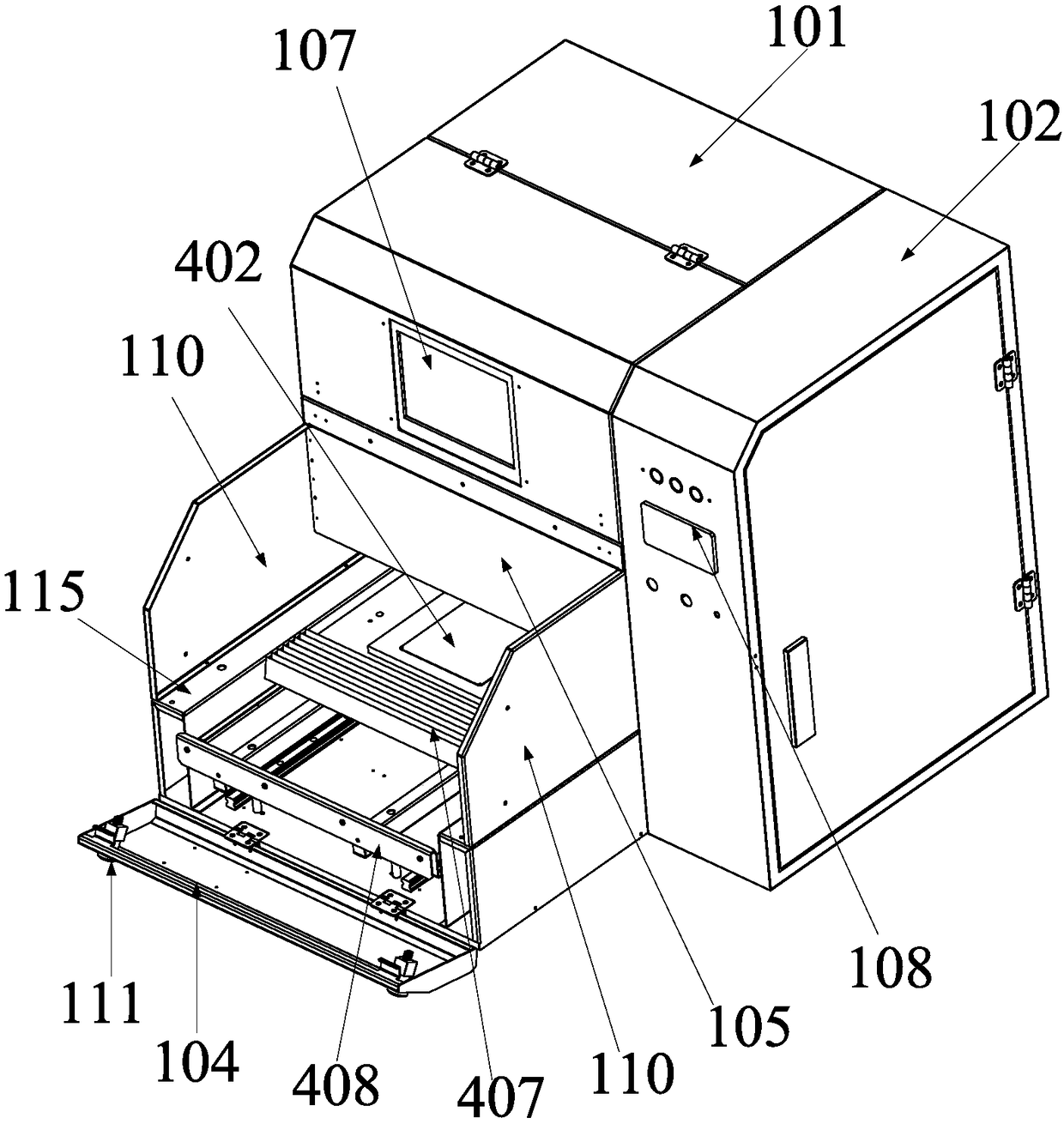

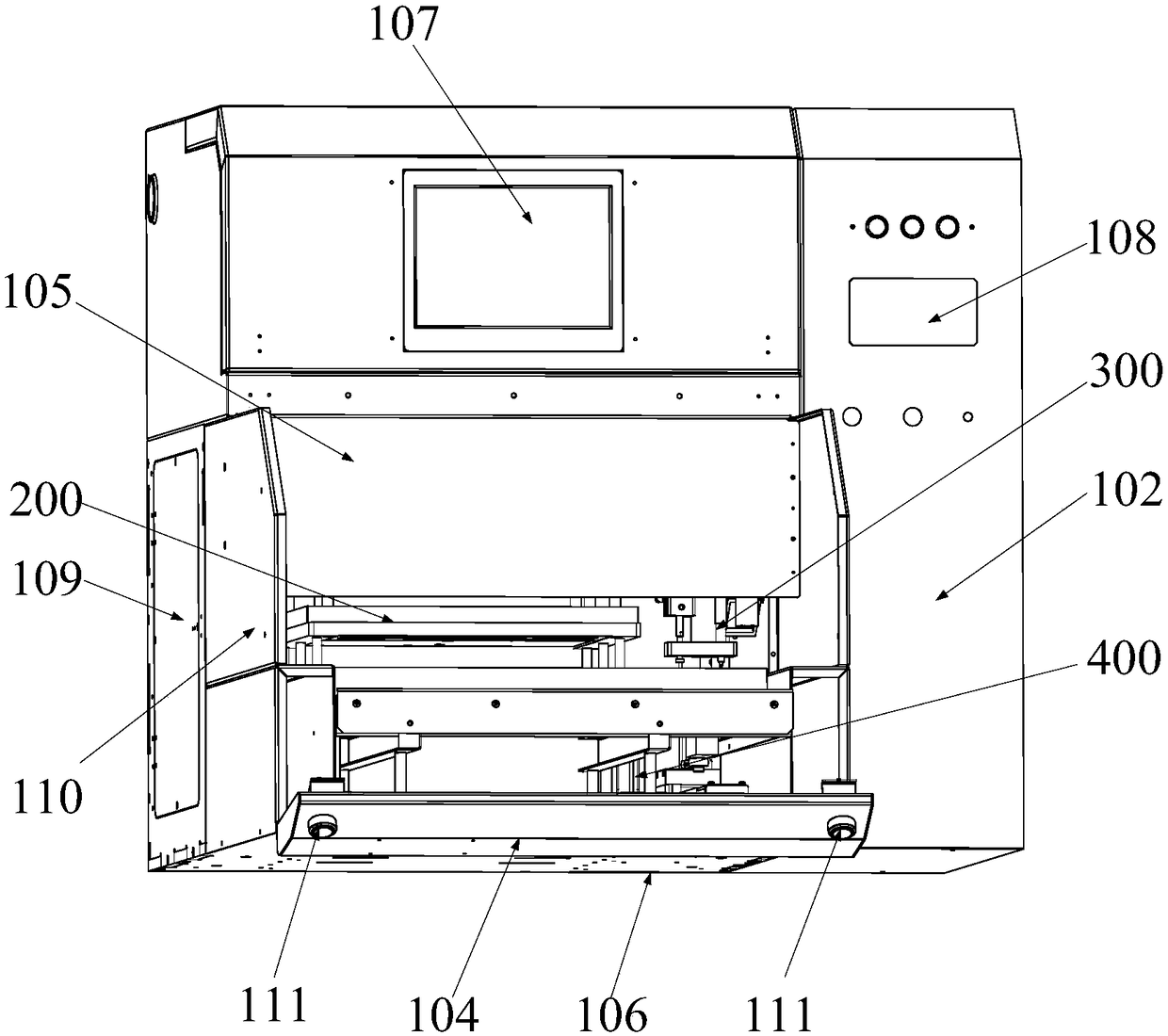

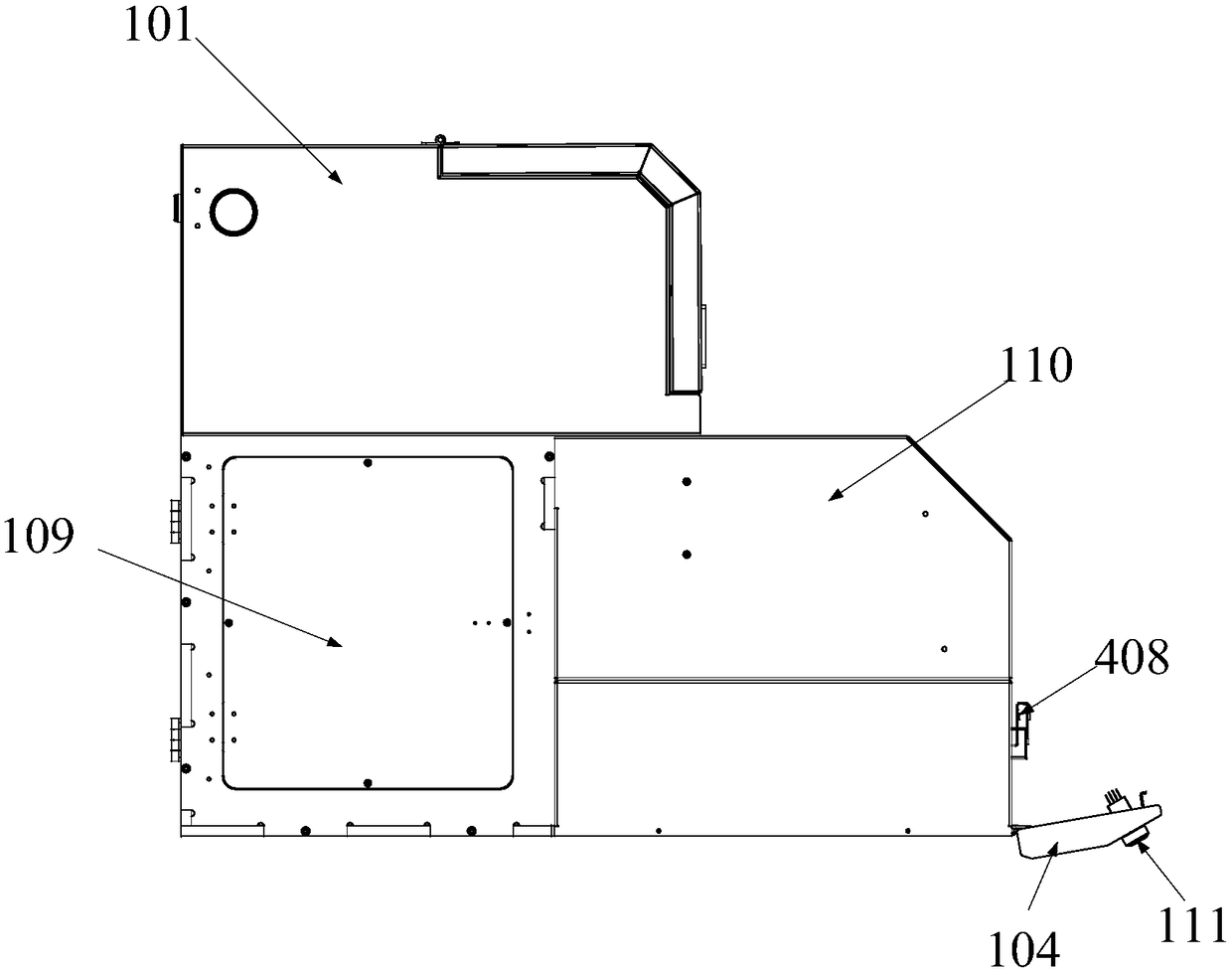

[0042] Such as Figure 1-Figure 10As shown, the circuit board detection equipment provided by the embodiment of the present invention includes: a body, a detection mechanism 200, a marking mechanism 300, a moving mechanism 400 and a control system are installed in the body, and the control system is connected with the detection mechanism 200, the marking mechanism 300 and the moving mechanism respectively. Mechanism 400 is connected.

[0043] The detection mechanism 200 includes a first driver 201 and a detection needle for detecting materials. The first driver 201 drives the detection needle to move along a first direction. Both the first driver 201 and the detection needle are connected to the control system.

[0044] The marking mechanism 300 includes a second driver 301 and a marking member 302, the marking member 302 is used for marking on materials, the second driver 301 drives the marking member 302 to move, and the second driver 301 is connected with the control system...

Embodiment 2

[0081] Embodiment 2 of the present invention proposes a testing system, which includes the circuit board testing device provided in Embodiment 1 above.

[0082] The testing system has the same advantages as the above-mentioned circuit board testing equipment over the prior art, and will not be repeated here.

[0083] Further, the testing system can also include a feeding device and a classification processing device, the feeding device is used to place the FPC soft board to be detected on the moving mechanism, and the classification processing device is used to combine the qualified products in the detected FPC soft board with Unqualified products are sorted out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com