Laser-labelable, halogen-free and flame-retardant polyamide composition and preparation method thereof

A technology of polyamide composition and flame-retardant polyamide, which is applied in the field of laser-markable halogen-free flame-retardant polyamide composition and its preparation, can solve the problem that polyamide composition cannot meet clear marking at the same time, and achieve marking speed Fast, good flame retardancy and electrical performance, low power effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

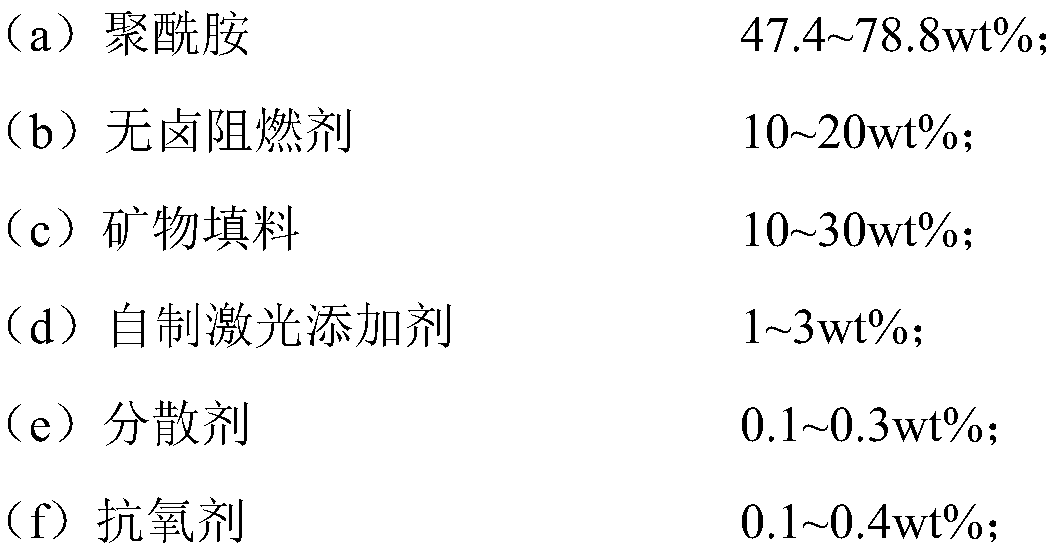

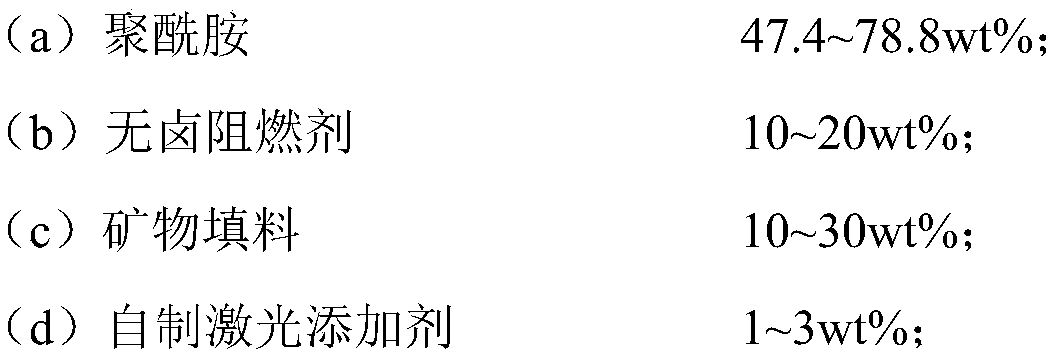

Method used

Image

Examples

Embodiment 1

[0068] Example 1, Example 2, Comparative Example 1 and Comparative Example 2, issued the performance of different filling systems and laser additive compositions on laser marking performance, these examples and comparative examples show the combination of adding self-prepared laser additive 1 Clear marking can be achieved under both infrared and ultraviolet laser marking machines. The laser marking effect is better than that of glass fiber when talcum powder is used as filler, and the mechanical properties are not significantly worse than those of the comparative example without laser additives. The comparative example without adding laser additives cannot achieve clear marking under both infrared and ultraviolet lasers.

Embodiment 3

[0069] Example 3, Example 4 and Comparative Example 3 show the laser marking performance of different flame retardant systems under glass fiber reinforcement. These examples and comparative examples show that the addition of laser additive composition 2 can achieve clear marking under ultraviolet and infrared lasers, and at the same time, the flame retardancy and electrical properties are not significantly deteriorated compared with comparative example 3 without adding laser additives. Examples 3 and 4 show that both MPP and OP1400 as flame retardants can achieve a flame retardancy level of 0.75mmV-0, but the composition using OP1400 has better mechanical properties. Examples 4 and 5 show that the addition of self-prepared laser additive 2 has a very good laser marking effect in the circular interface and glass fiber filling system with special-shaped cross-section, and the composition using glass fiber with special-shaped cross-section has better mechanical properties. .

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com