Method for building comprehensive coke ratio predicting model and predicting comprehensive coke ratio

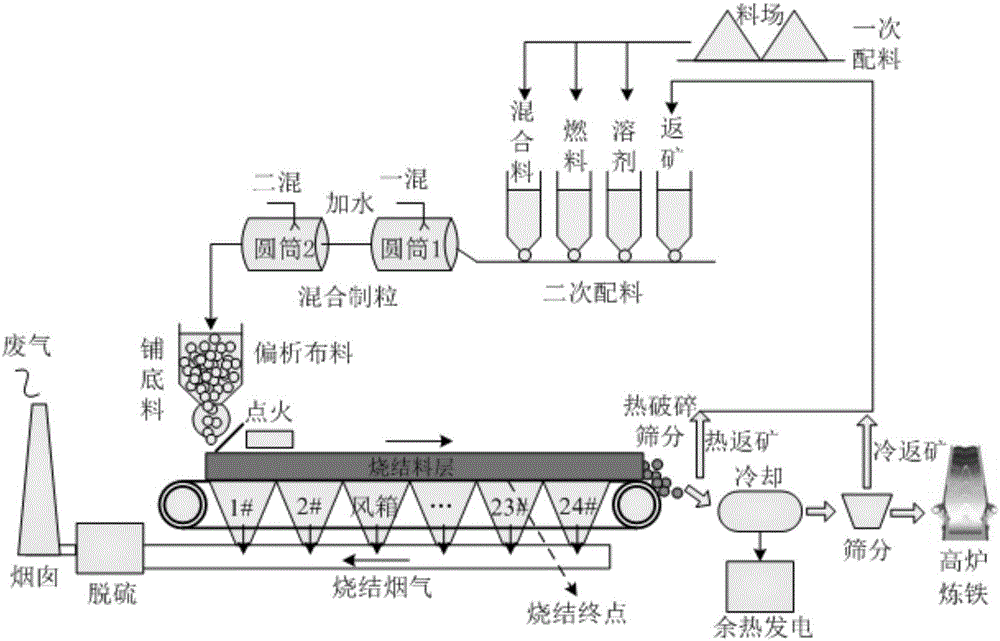

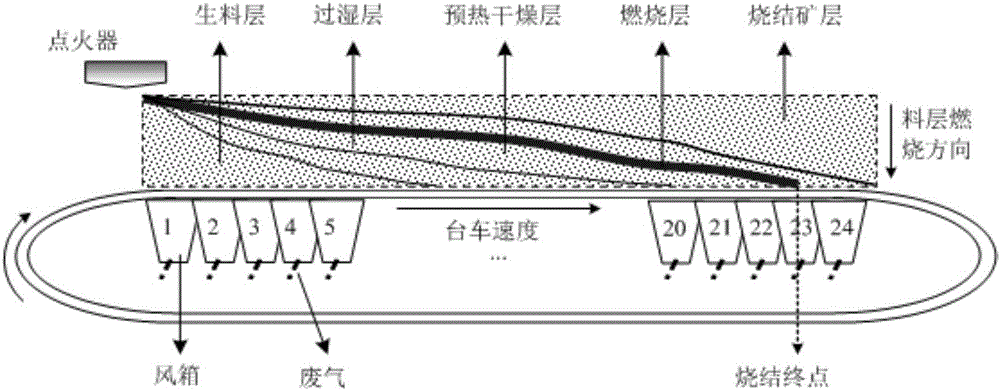

A prediction model and focal ratio technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as nonlinearity, complex mechanism, strong coupling, etc., achieve wide application, overcome coupling problems, ensure accuracy and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

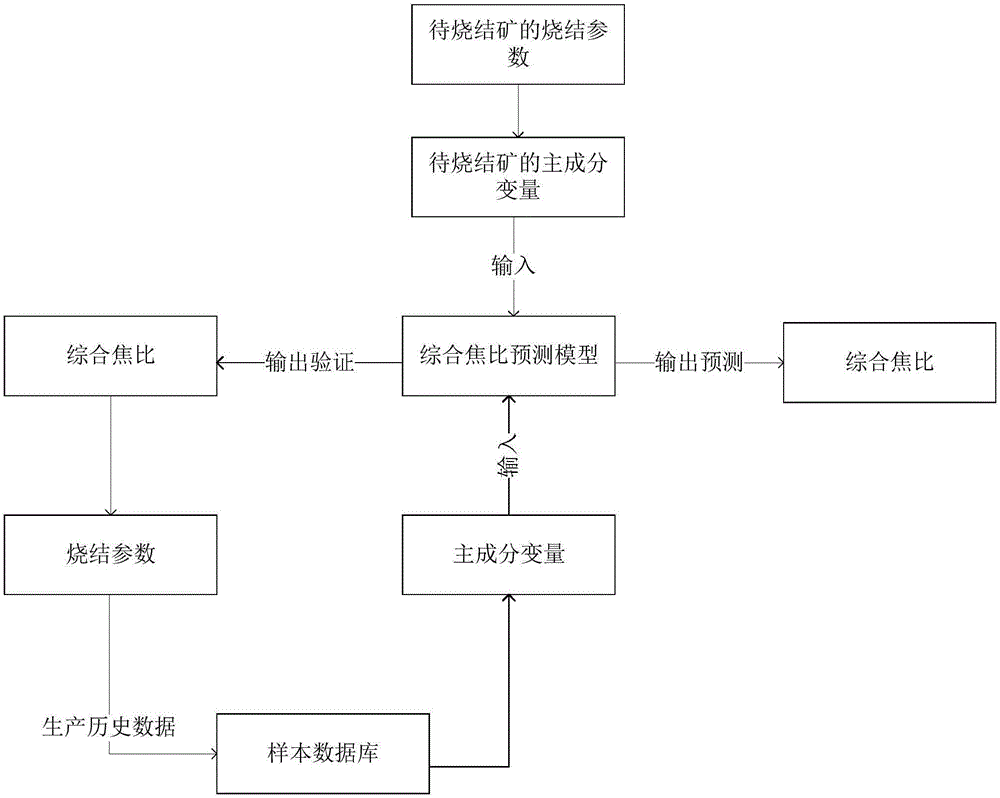

[0061] Please refer to the attached image 3 , this embodiment includes the following steps:

[0062] (1) The comprehensive coke ratio is the amount of coke converted from the fuel consumed per ton of molten iron production. Improving the utilization rate of coke is the prerequisite for ensuring the output and quality of sinter. Therefore, the comprehensive coke ratio is selected as an index to measure the carbon efficiency of the sintering process , and calculate the comprehensive focal ratio, the calculation formula of the comprehensive focal ratio is as follows:

[0063]

[0064]

[0065] In the formula: η represents the comprehensive coke ratio (Kg / t), w c Indicates the ratio of coke powder (%), p indicates the yield (%), q indicates the burning loss rate (%), Q D Indicates the large ore-forming output of sintering (Kg / h), Q X Indicates the small ore-forming output of sintering (Kg / h), Q F Indicates the amount of sintered ore returned (Kg / h), Q P Indicates the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com