Construction process of wind power tower tube

A technology for wind power towers and processes, which can be used in manufacturing tools, sustainable manufacturing/processing, arc welding equipment, etc., and can solve problems such as affecting construction accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057]The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

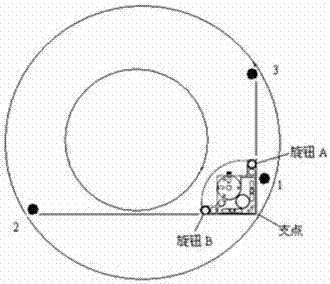

[0058] The construction process of the wind power tower of the present invention is specifically realized through the following steps: including the fabrication of sectioned tube sections, installation of tower tube flanges and tower tube assembly processes.

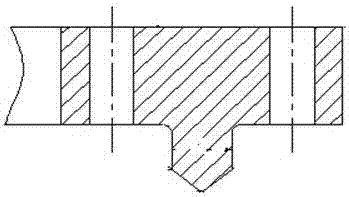

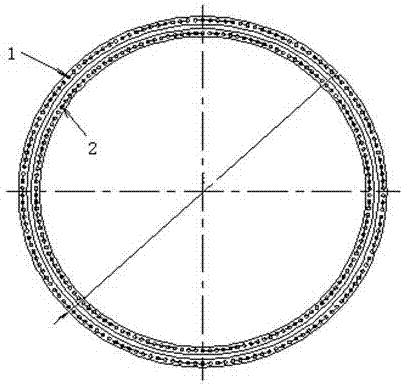

[0059] 1. Segmented cylinder section production:

[0060] Including raw material incoming inspection, material re-inspection, steel plate pretreatment, CNC cutting and blanking, dimensional inspection, groove processing, rounding, welding longitudinal seam, round calibration, cylindrical section ellipticity measurement, 100% UT and T-shaped seam 100% MT testing process.

[0061] In the production of segmented cylinders, the requirements for the blanking of cylinder joints are: the full-time quality inspector of the qu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com