Weighing check method for belt weighers

A calibration method and belt scale technology, applied in the field of electronic calibration, can solve problems such as production interruption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

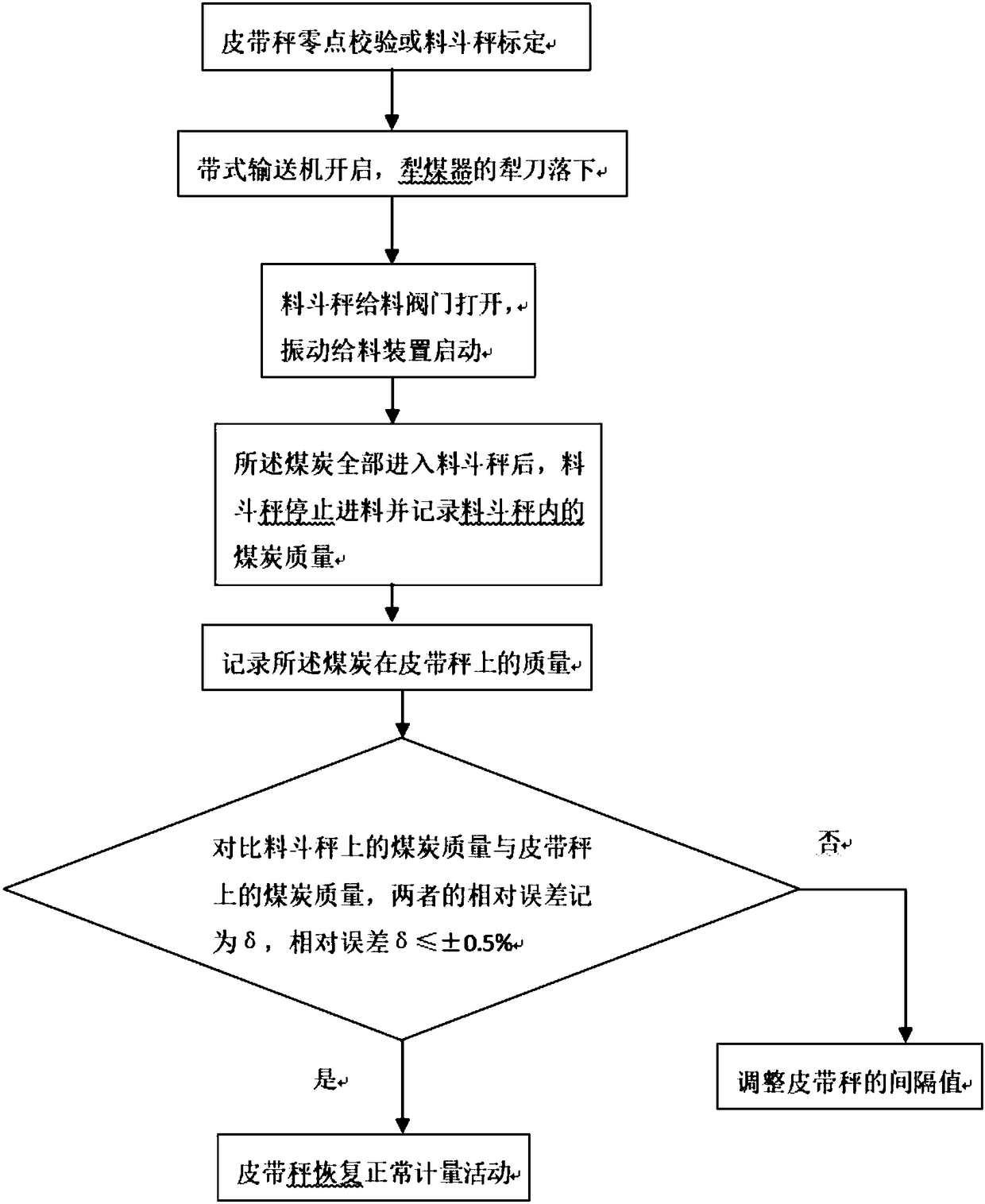

[0018] A weighing verification method of a belt scale, such as figure 1 shown, including steps:

[0019] S1. Belt scale zero point calibration or hopper scale calibration;

[0020] The steps of zero-point verification of the belt scale include: pre-setting the quality Z of the standard empty belt scale, and the straight line is y=Z; the belt scale runs stably for 30 minutes under the condition of no load; records the change of the quality of the empty belt scale with time, and depicts Zero-point drift curve; compare the straight line with the zero-point drift curve, count the number of times N that the zero-point drift curve crosses the described zero-point curve, if N>0, then record the empty belt scale quality data every 3 minutes, the data Sum denoted as ∑Z i , calculate and obtain the deviation error of the mass of the empty belt scale: K=(∑Z i / N-Z) / Z×100%, the belt scale corrects the range calibration number E of the belt scale according to the deviation error K, obta...

Embodiment 2

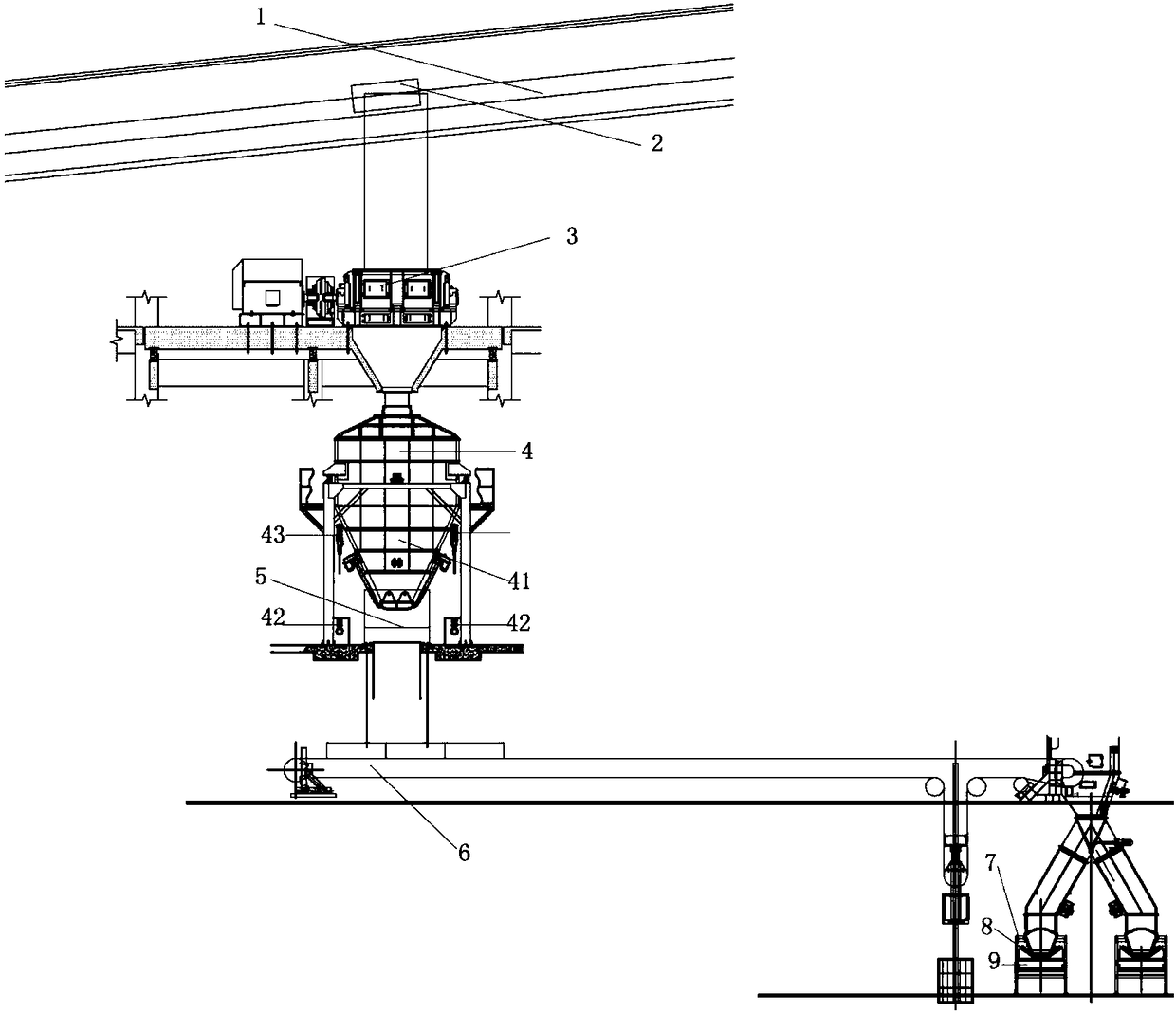

[0029] A kind of belt scale measurement verification device, such as figure 2 As shown, the belt conveyor 1 is connected to the coal plow 2, the coal plow 2 is connected to the coal crusher 3, the coal crusher 3 is connected to the hopper scale 4, the discharge port of the hopper scale 5 is connected to the feeding belt conveyor 6, and the hopper scale 5 is connected to the Feeding belt conveyor 6 is all positioned at belt scale 7 tops, and described belt scale 7 is communicated with feed bin belt conveyor 8, and feed bin belt conveyor 8 is connected with feed bin 9. The belt conveyor 1 is used to transport coal, and the coal plow 2 unloads the coal on the belt conveyor 1, and imports it into the coal crusher 3, and after processing it into fine coal, it enters the hopper scale 4 for weighing, and the weighed The fine coal is transported by the feeding belt conveyor 6 and then weighed in the belt scale 7, and the data of the two is compared, and the belt scale 7 is checked. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com