Stirring building or station embedded control system

An embedded control and mixing plant technology, applied in mixing plants, control devices, mixing operation control, etc., can solve the problems of poor moisture resistance, low reliability, single overshoot control means, etc., to solve system instability , Improve system stability, change the effect of complex wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

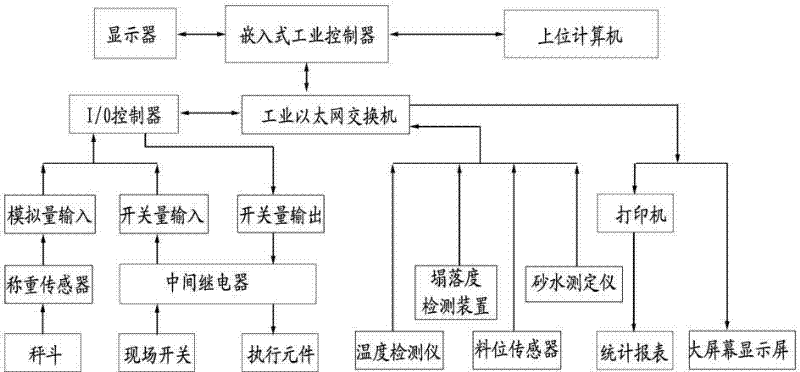

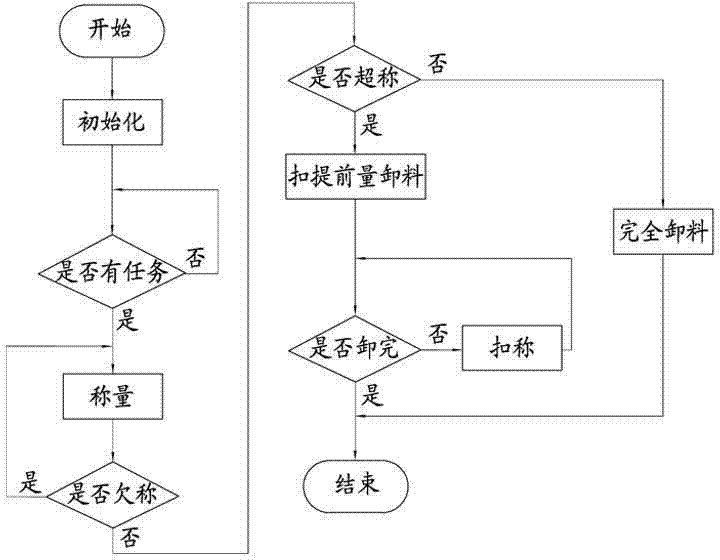

[0020] like figure 1 , 2 As shown in the figure, the embedded control system of the mixing building and station of the present invention includes an embedded industrial controller (PAC: Advantech UNO-2170KW, 1.6GHz, with a 512KB secondary cache processor; memory: 512M, and an additional 200pin DDR memory expansion slot; supports wide-range DC / AC power input, dual network ports, 4COM, 5USB 2.0, CF card, PC / 104+ expansion interface); the communication interface of the embedded industrial controller is respectively connected with the display, host computer, Industrial Ethernet switch (EKI-2525; 5 10 / 100Mbps Ethernet ports; 8-slot distributed rack: ADAM-5000 / TCP; CPU: RISC; Memory: 4M) communication connection; the industrial Ethernet switch communication interface An I / O controller (ADAM-5055S; 8 inputs; 8 outputs; electrical isolation: 2500VDC.) is connected; the signal input interfaces of the I / O controller respectively pass through the analog input module (ADAM-5017P; disting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com