Furnace top stock-level detection system for blast furnace

A detection system, blast furnace technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve the problems of time-consuming, complicated zero point calibration process, etc., and achieve the effect of simplifying debugging steps and saving manpower and material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

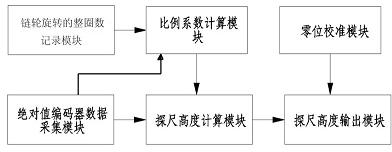

[0018] figure 1 It is a structural diagram of the hardware system of an embodiment of the present invention. The system is composed of a PLC controller, a master controller, a frequency converter, a motor, a sprocket, a weight, an incremental encoder and an absolute value encoder. The PLC controller receives The signal of the master controller and the absolute value encoder; the frequency converter is connected with the PLC controller and the motor, the incremental encoder is connected with the frequency converter and the motor; the motor is connected with the sprocket to drive the forward and reverse rotation of the sprocket, and the absolute value The encoder is connected to the sprocket.

[0019] In this embodiment, the probe is selected as a probe with a maximum measuring range of 6 m, and the absolute value encoder is a 16-bit single-turn encoder.

[0020] The PLC co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com