All-in-one machine for sewage sludge treatment

A sewage sludge and integrated machine technology, which is applied in the fields of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of large land occupation per ton of water, large energy consumption, inability to continuously operate slag removal, and complex sludge treatment devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

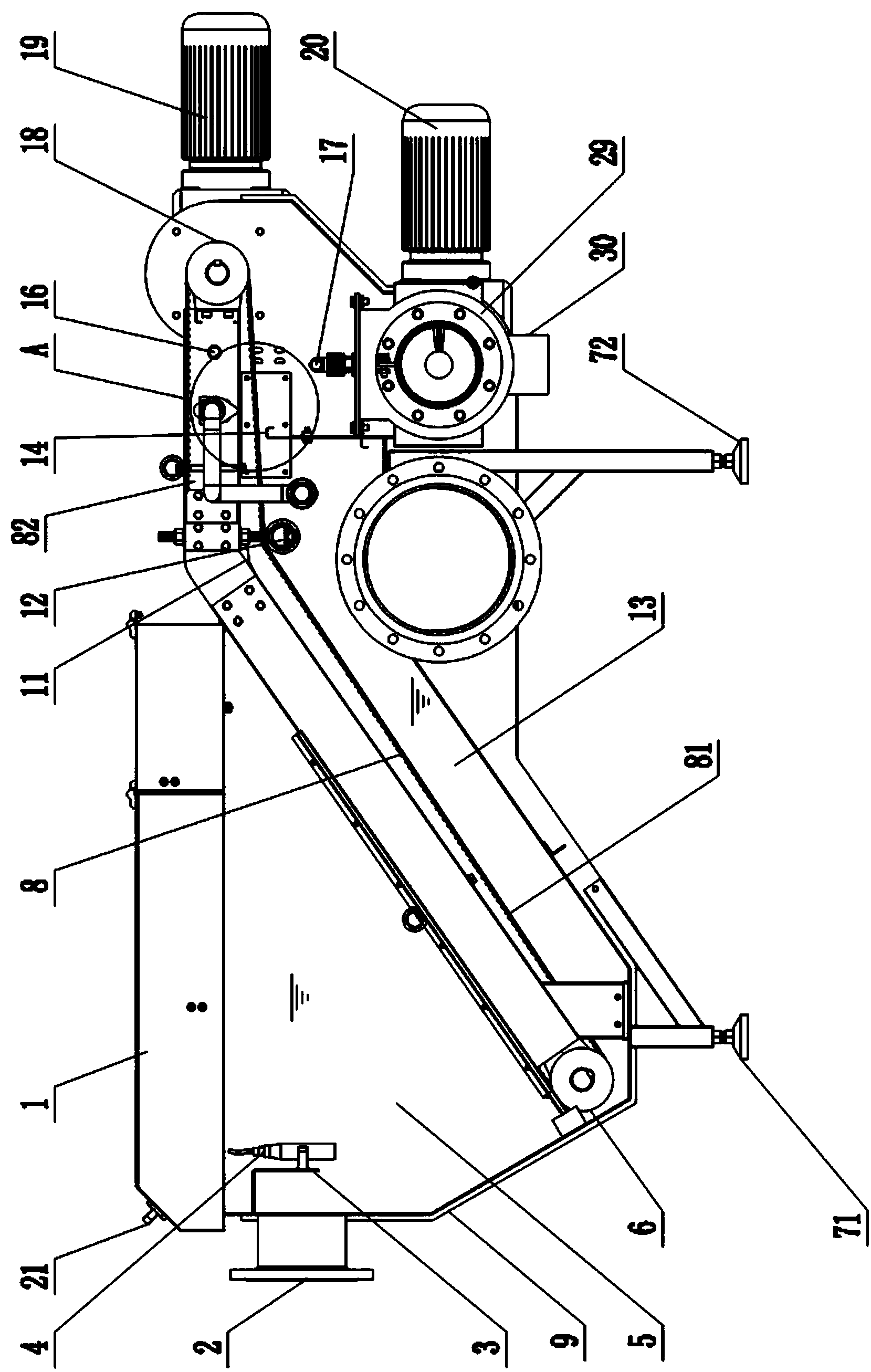

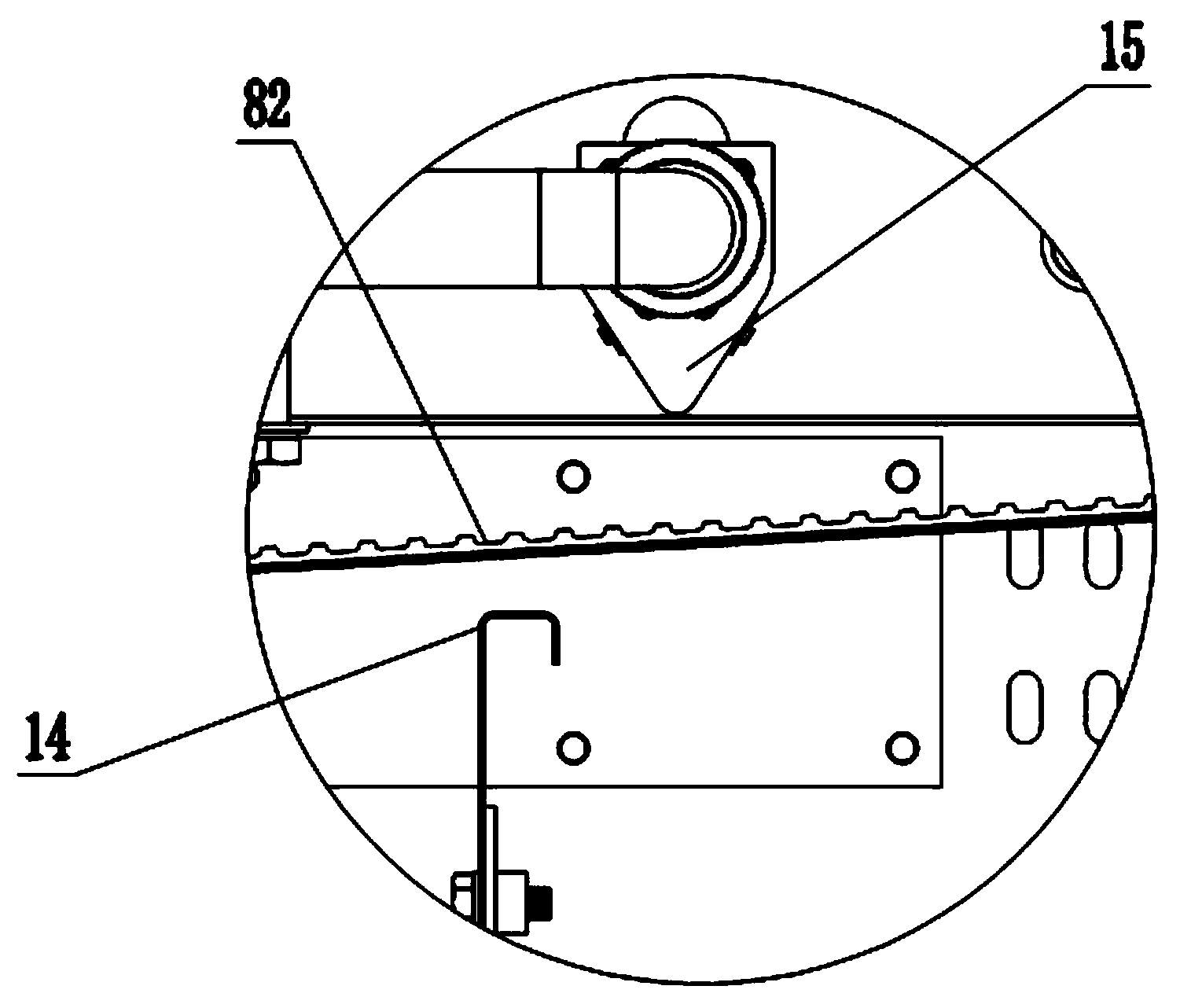

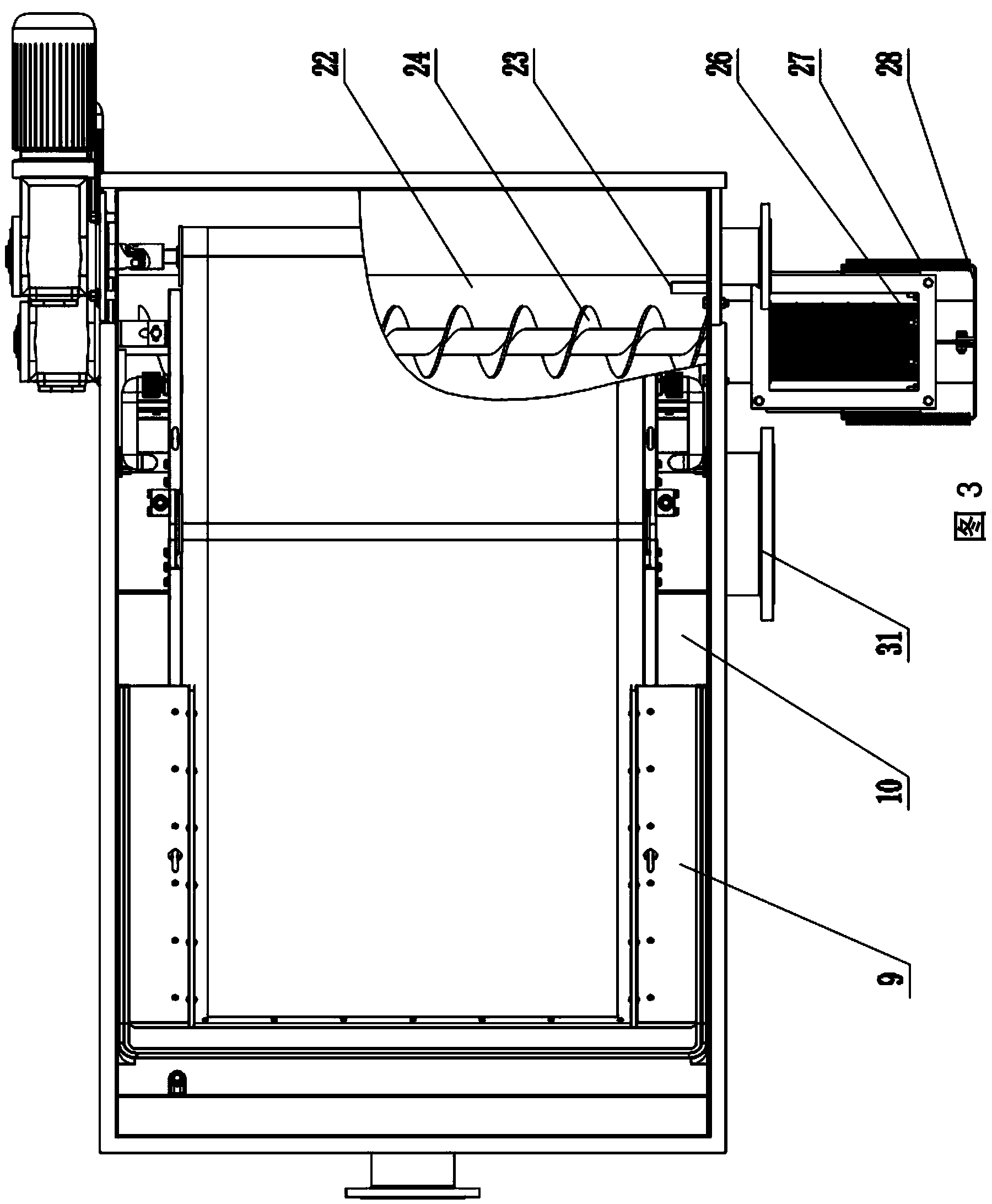

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0024] see Figures 1 to 3 As shown, an integrated sewage and sludge treatment machine includes a housing 9 and a front leg 71 and a rear leg 72 for supporting the housing 9 . The casing 9, the front leg 71 and the rear leg 72 of the sewage sludge treatment integrated machine are made of high-quality stainless steel. Both the front leg 71 and the rear leg 72 are adjustable legs, and in actual use, the front leg 71 and the rear leg 72 can be adjusted according to the needs of the actual terrain. The housing 9 is provided with a sewage filter tank 5 for communicating with the outside to store sewage, a clean water tank 13 arranged below the sewage filter tank 5, and a clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com