Grinding machine with a dust removal function

A grinding machine and grinding wheel technology, applied in the fields of grinding, polishing devices, and dust removal grinders, can solve the problems of incomplete dust removal, affecting the filtering effect, and low service life, achieving good dust removal and noise reduction effects, and convenient cleaning of dust particles. The effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

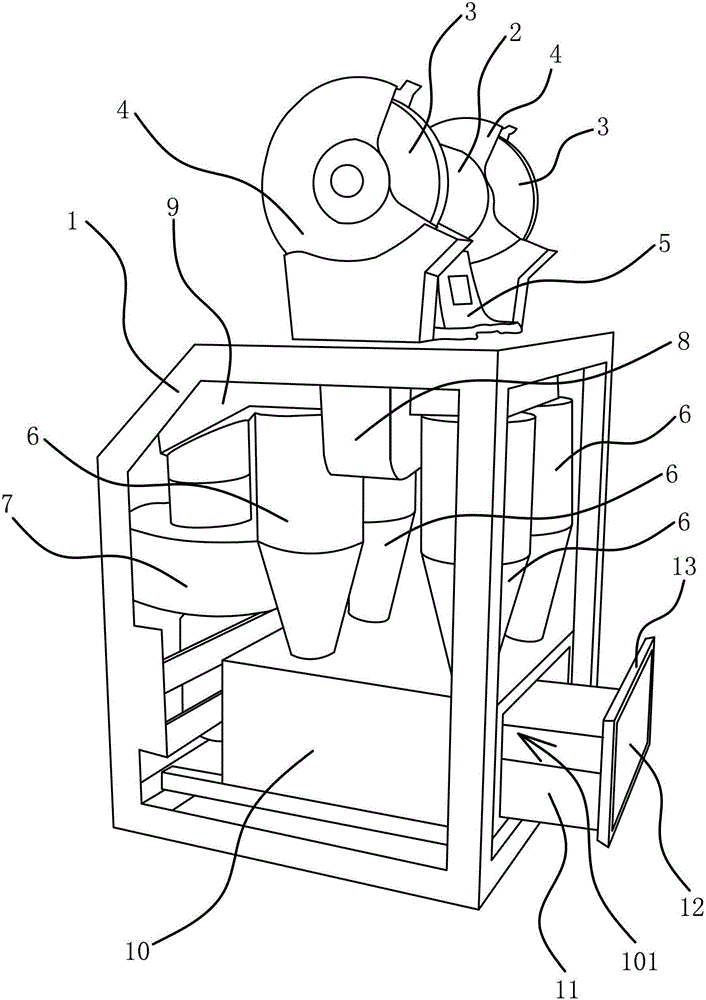

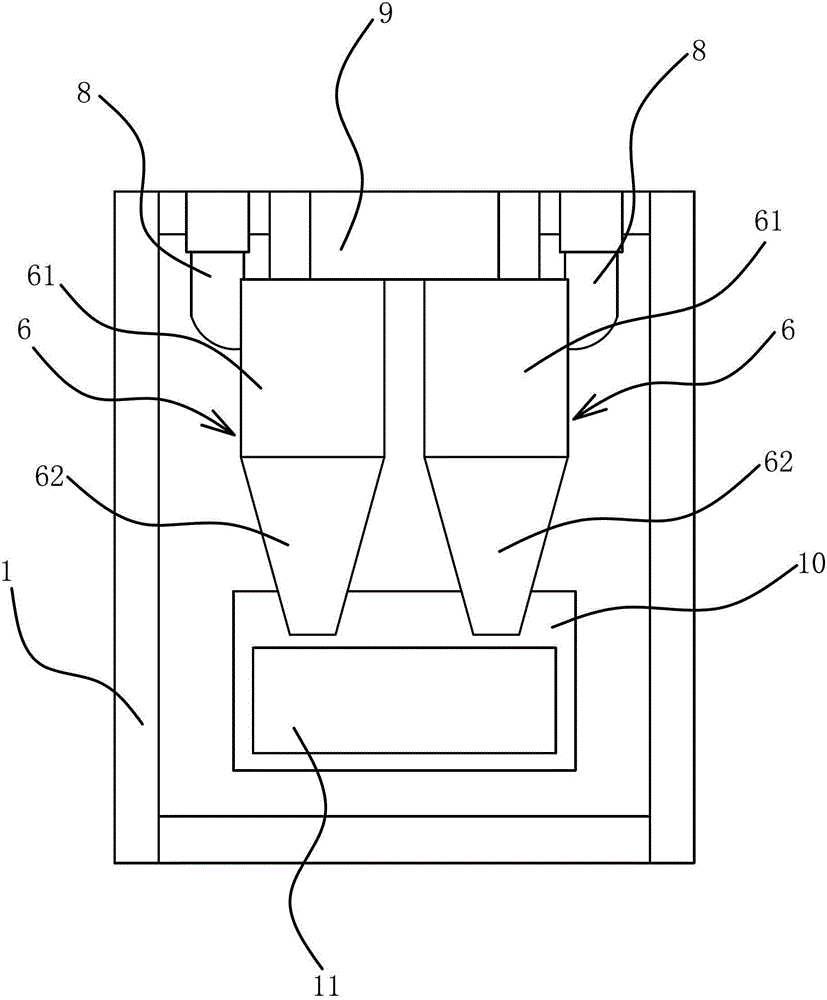

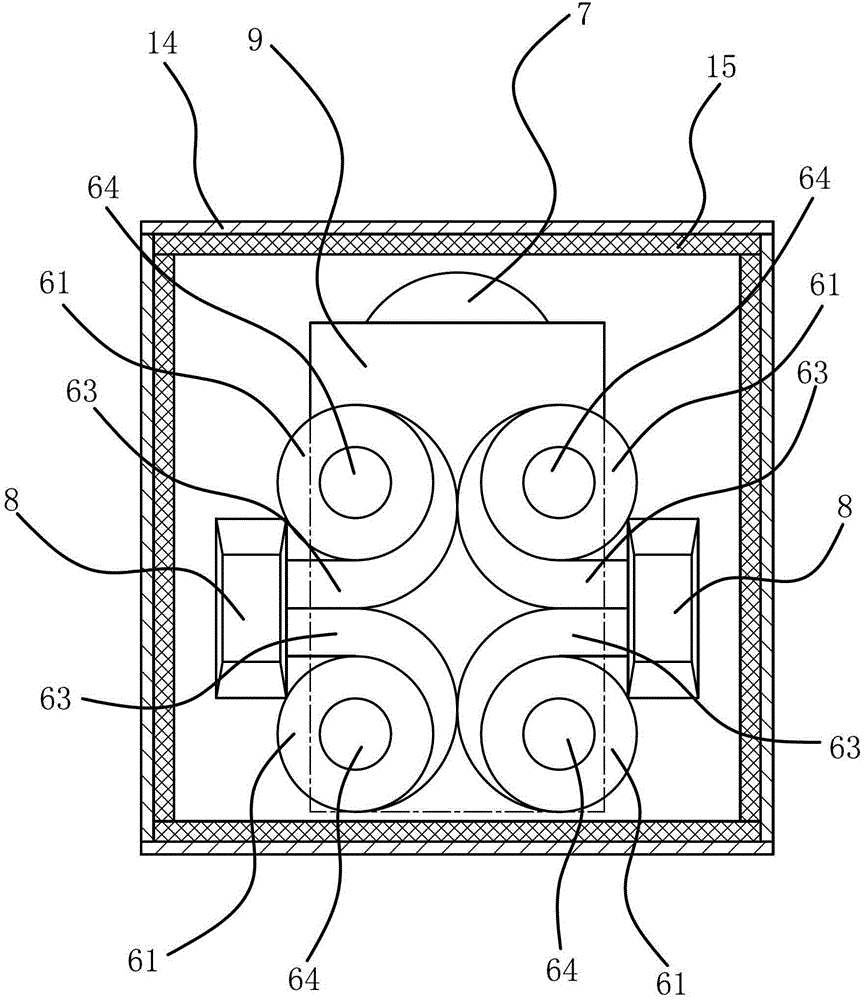

[0028] Such as figure 1 Shown, this dedusting grinder comprises workbench 1, motor 2, emery wheel 3, dust suction cover 4, blower fan 7, dust collection mechanism and cyclone dust removal mechanism 6.

[0029] Specifically, a base 5 is fixed on the table top of the workbench 1, the motor 2 is fixed on the base 5, and a grinding wheel 3 is arranged on both sides of the base 5, and the grinding wheel 3 is fixed on the base by a lock nut. On the motor 2 shaft. Two dust collection covers 4 are fixed on the workbench 1, and the dust collection covers 4 and the grinding wheels 3 are arranged in one-to-one correspondence, and the grinding wheels 3 are located in the corresponding dust collection covers 4.

[0030] Blower fan 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com