Refrigerator handle bending device

A bending device and handle technology, applied in the field of stamping, can solve the problems of low production efficiency, difficult operation, high production cost, etc., and achieve the effect of reasonable and compact design, high degree of automation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings:

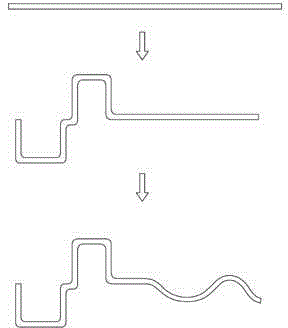

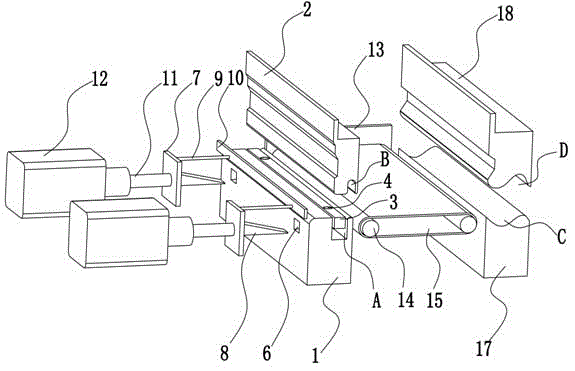

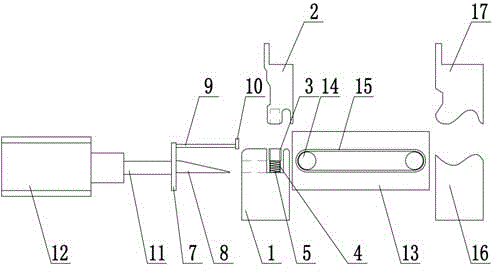

[0022] Such as Figure 1 to Figure 5 As shown, the technical solution adopted by the present invention is as follows: a refrigerator handle bending device, including a first bending component, a feeding component, a transmission component, and a second bending component, wherein the first bending component includes The lower bending die 1, the upper bending die 2 and the buffer plate 3, the lower bending die 1 and the upper bending die 2 are set up and down correspondingly; the buffer plate 3 is set in the lower bending die 1, and the workpiece to be processed is placed in the lower bending Between the bending die 1 and the upper bending die 2, the upper bending die 2 is pressed down into the lower bending die 1 to complete the first bending of the workpiece to be processed; the above-mentioned feeding assembly is set on the side of the lower bending die 1 , The feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com