Method for shaping bar array large power semiconductor laser device added with guide light

A semiconductor and laser technology, applied in the field of LD, to achieve the effect of compact and reasonable optical path design, precise control, and ensure the stability of the optical path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

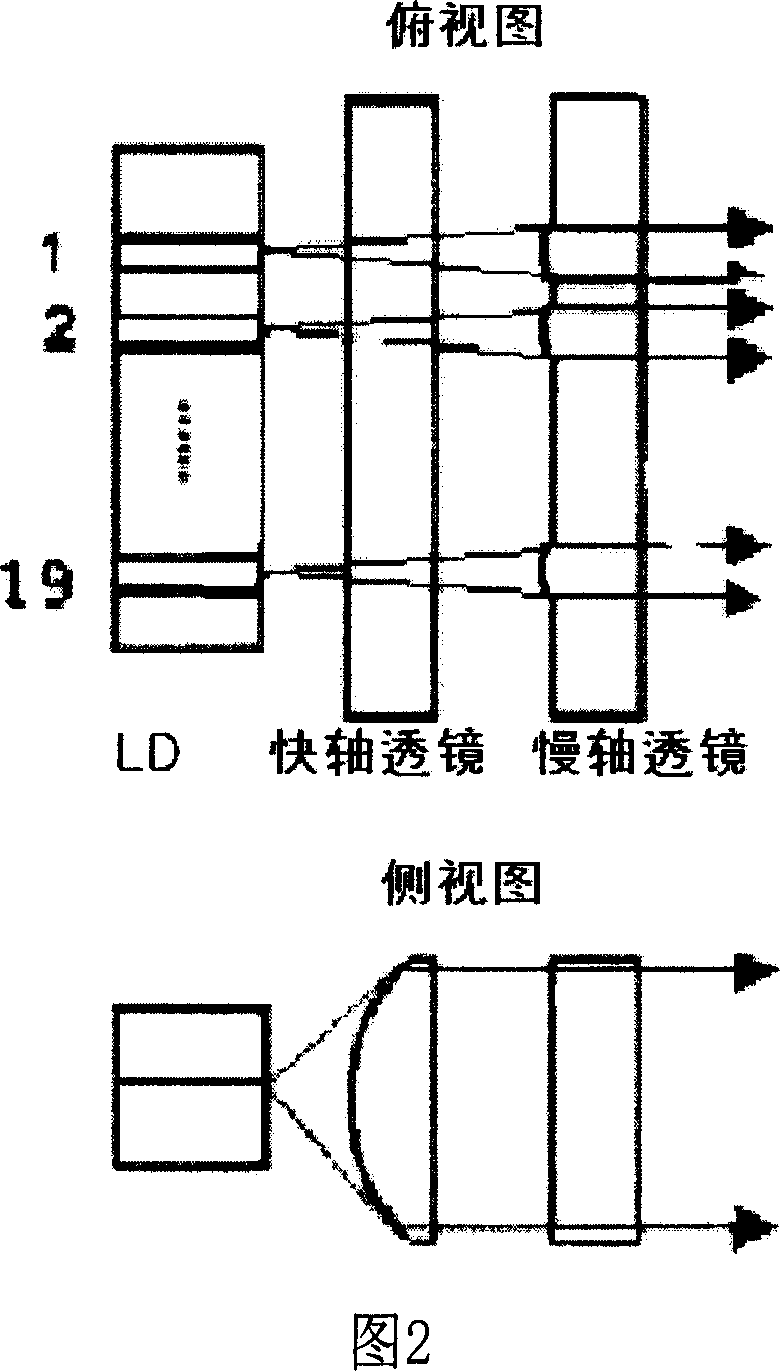

[0038] Example 1, using a domestic 40W continuous wave LD with a wavelength of 808nm and a 10mW light source with a wavelength of 650nm, through the above optical path for design, processing and assembly, coupled to an optical fiber with a core diameter of 400 μm and a numerical aperture of 0.37, the final output power is LD output power of 28.2 watts , the guided light output is 5.2 milliwatts, and the specific process is as follows:

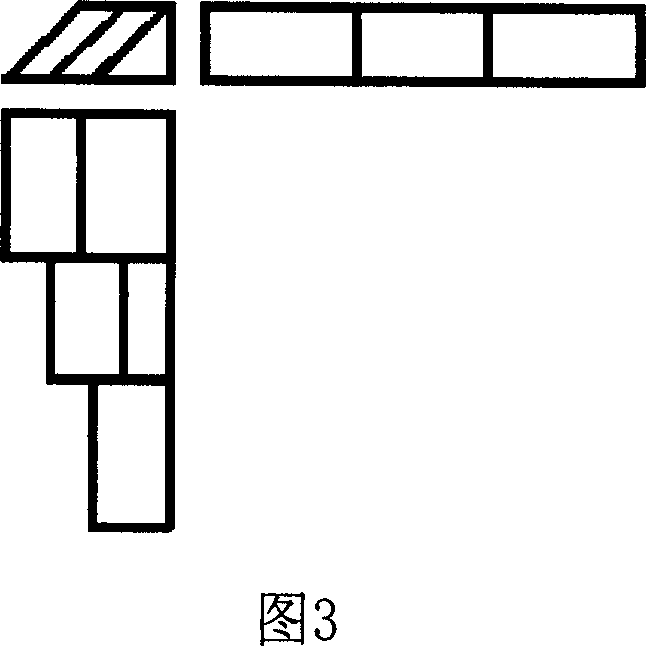

[0039] (1) For an optical fiber with a core diameter of 400 μm and a numerical aperture of 0.37, it is calculated by formula (2) that the principle of optical parameter product matching can be satisfied by folding the LD beam three times. Therefore, it is necessary to make a 3-fold reflective device in this system.

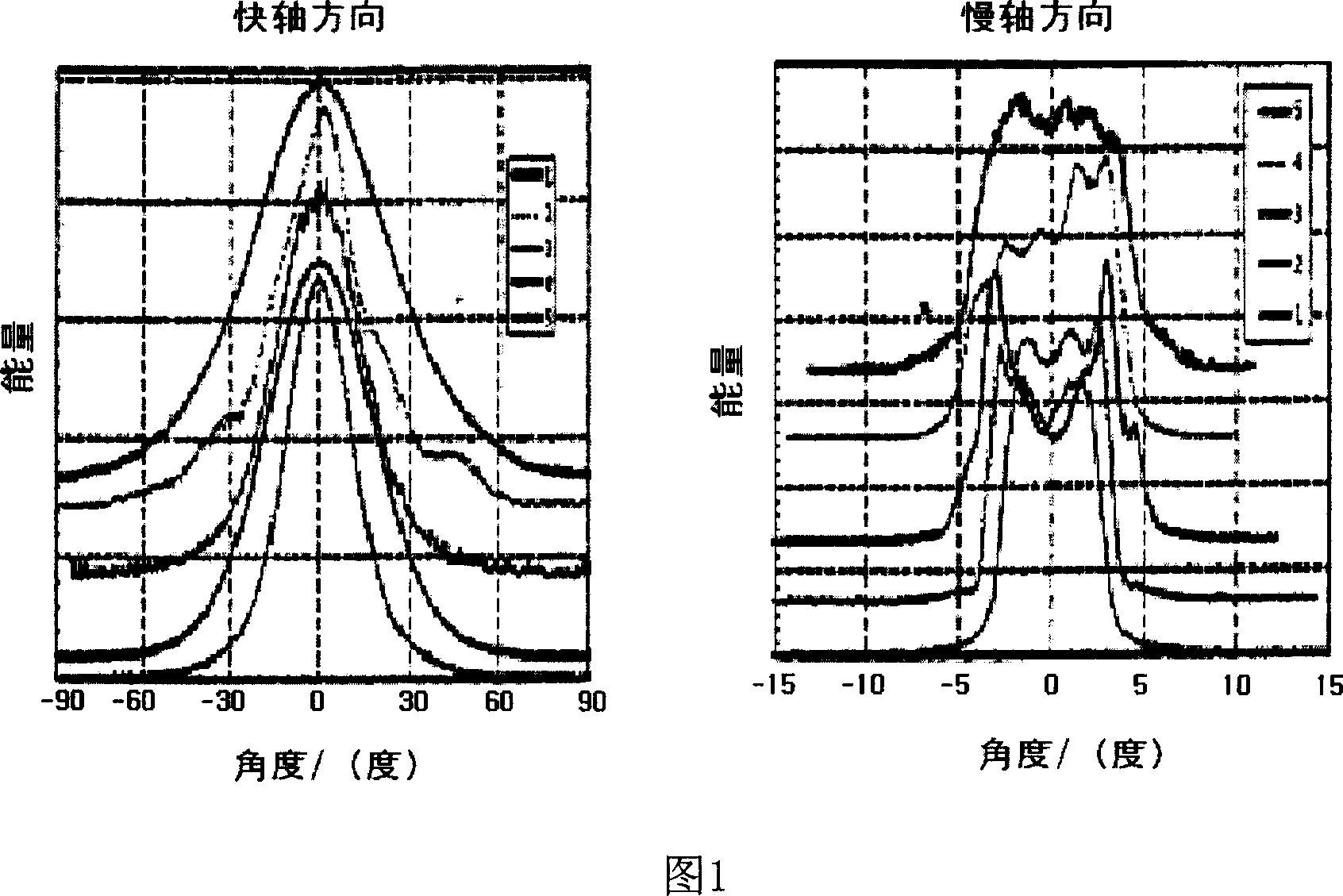

[0040] (2) Realize the alignment of LD(λ 1 =808nm) collimation, the collimated light beam becomes a quasi-parallel light beam. After testing, the divergence angle in the fast axis direction is 10.2mrad, the spot length is 0.6mm, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com