Automatic grain screening machine

An automatic screening and grain technology, applied in the direction of sieve, solid separation, grille, etc., can solve the problems of waste, high energy consumption, pollution of natural environment and working environment, etc., to ensure the effect of food hygiene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

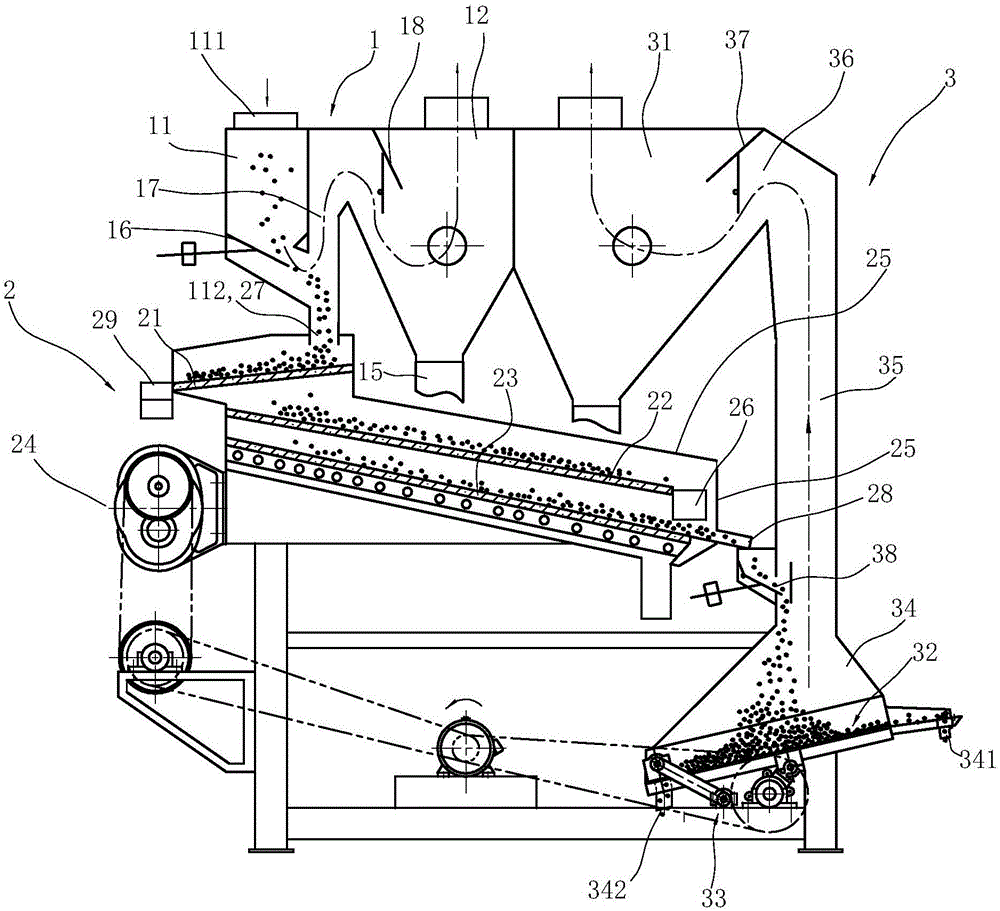

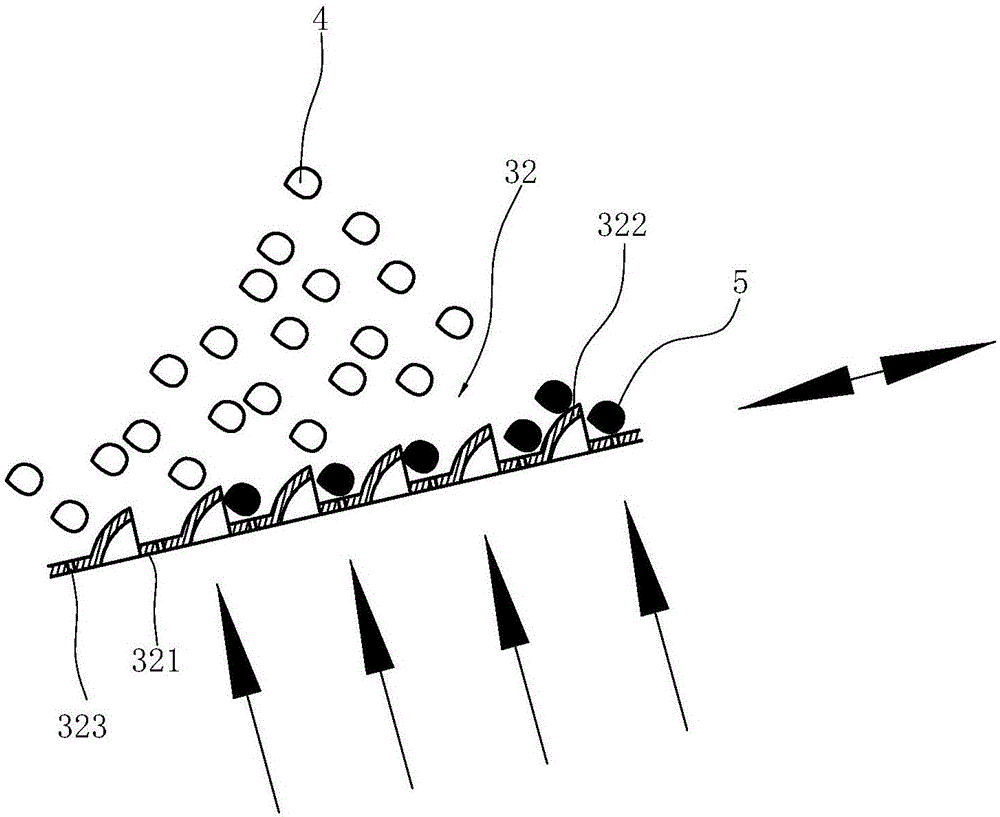

[0023] Such as figure 1 and figure 2 As shown, the grain automatic screening machine includes:

[0024] Suction separation device 1 is used to remove light impurities in grains, such as leaves, bran, chaff, etc.; it includes a feed chamber 11 and a first suction chamber 12 arranged side by side.

[0025] The feed port 111 of the feed chamber 11 is arranged on the top of the feed chamber 11, and the feed outlet 112 is arranged on the bottom of the feed chamber 11; the feed chamber 11 is also provided with a feed regulating valve 16 for controlling the amount of feed .

[0026] The first suction chamber 12 is connected to the suction device, and its bottom is an inverted cone, and its bottom is provided with a discharge port 15; the first suction chamber 12 and the feed chamber 11 are connected through the first pipeline 17, and the first pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com