Vegetable distribution box, automatic feeding mechanism and manufacturing method

A technology of automatic feeding and manufacturing methods, applied to cooking utensils, household appliances, applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

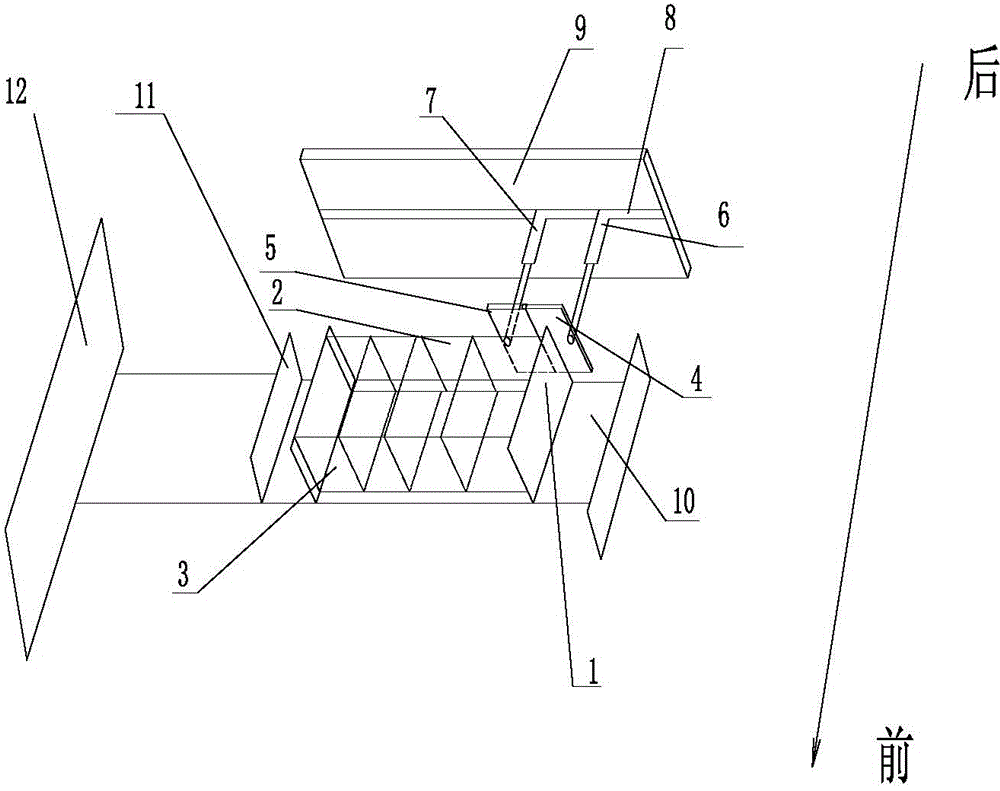

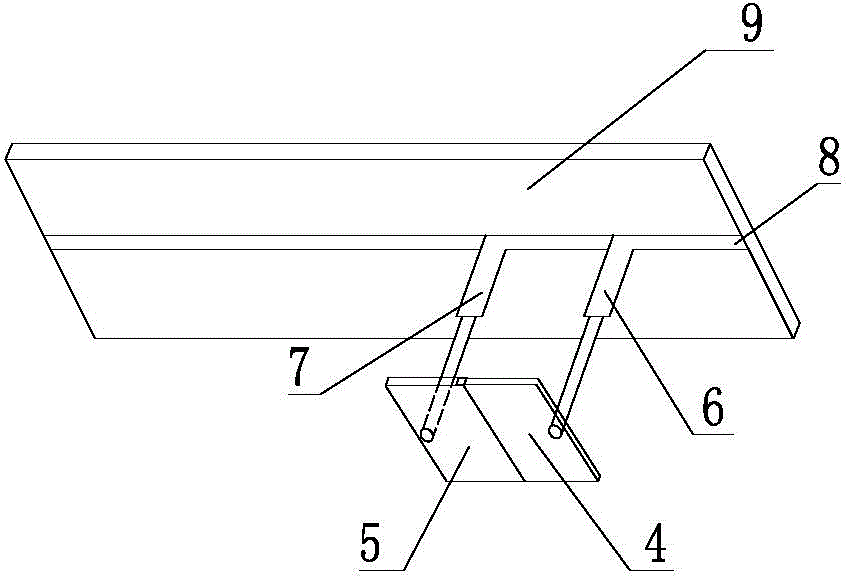

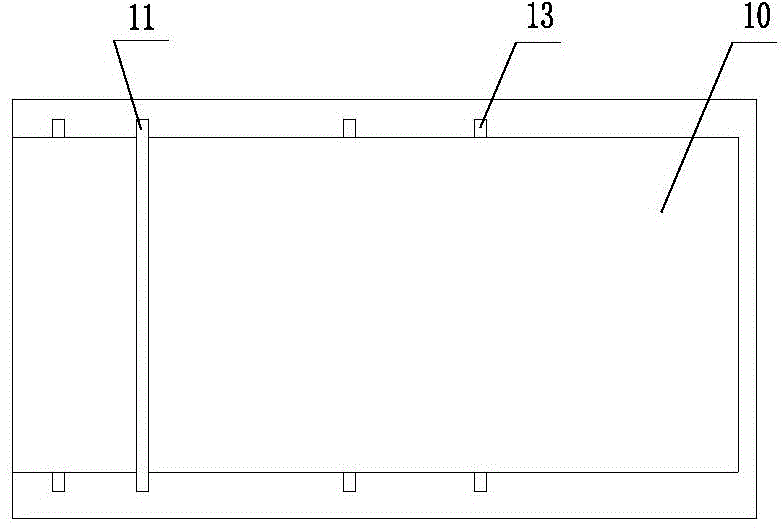

[0019] The side dish box and the automatic feeding mechanism of the present invention are used for home cooking robots, including the side dish box, the automatic feeding mechanism, the electrical part connected with the electric control of the cooking robot, the right side 12 of the cooking robot housing and the rear housing 9 of the cooking robot. set for inner right angles, see figure 1 , which is characterized in that the wide side of the side dish box 1 is placed in the groove of the support plate 10, and is vertically fixed to the right side 12 of the cooking robot housing through the support plate 10; the roots of the right telescopic rod 7 and the left telescopic rod 6 of the automatic feeding mechanism are vertically embedded in the cooking In the horizontal slideway 8 on the robot rear housing 9, the right telescopic link 7 and the left telescopic link 6 front ends vertically fix the left push pedal 4 and the right push pedal 5 respectively; The middle part is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com