A device for realizing double-ended automatic crimping of butt terminals

A crimping device and terminal technology, applied in the direction of connection, electrical components, circuits, etc., can solve the problems of electrical system reliability reduction, slow speed, poor contact, etc., and achieve the effect of convenient threading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

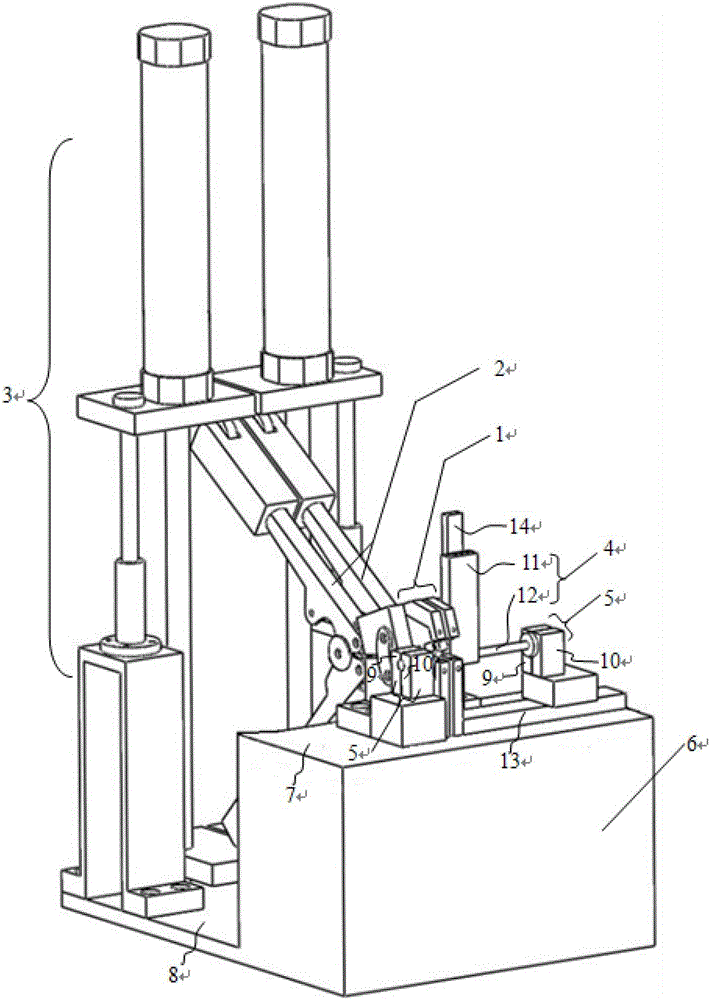

[0020] Such as figure 1 As shown, the device of the present invention includes a pliers assembly 1, a pliers arm assembly 2, a terminal box assembly 4, a left threading guide assembly 4, a right threading guide assembly 5, a base 6, a left threading guide assembly 4, a pliers assembly 1, and a guide rail I13 and the guide rail II14 are respectively fixed on the corresponding positions of the front frame 7 of the base, the terminal box assembly 3 is installed on the guide rail I13, the right threading guide assembly 5 is installed on the guide rail II14, the clamp arm assembly 2 and the pressure clamp are placed on the back frame 8 of the base Component 1 is hinged.

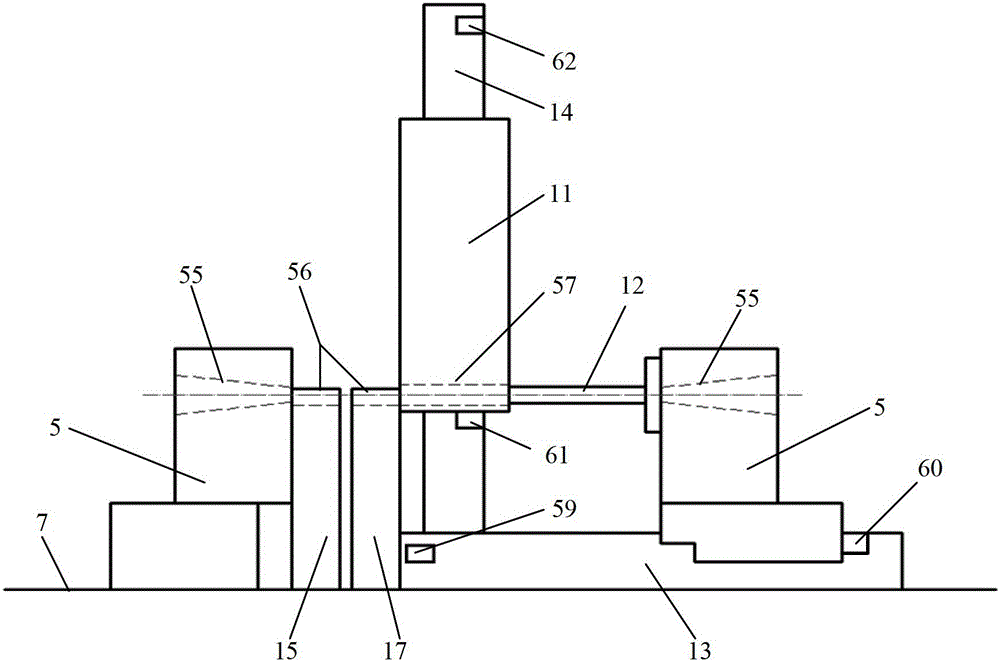

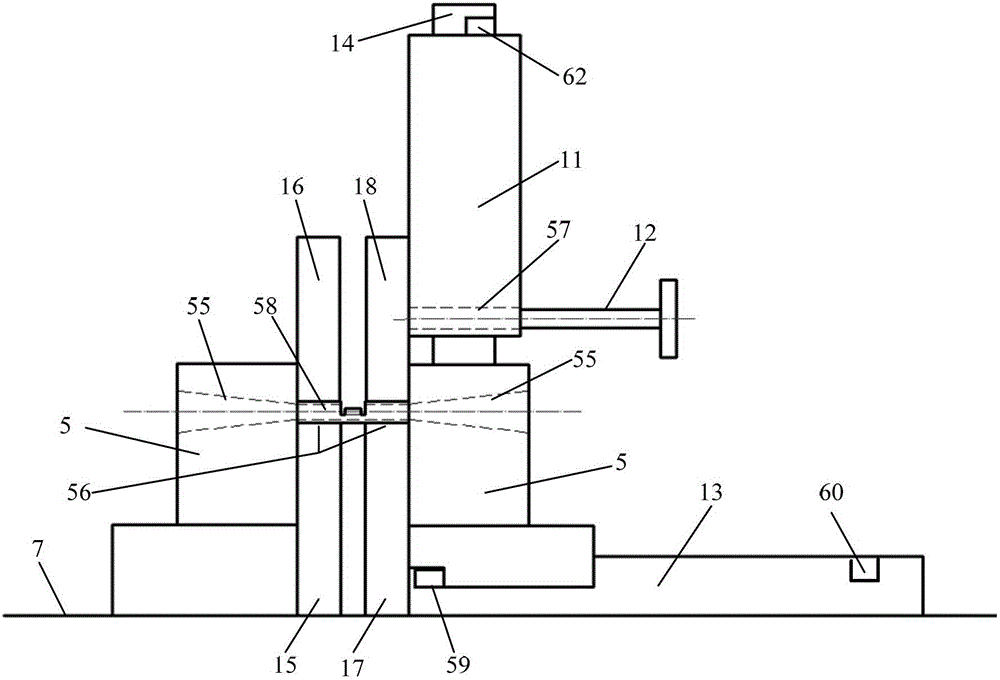

[0021] The axis of the tapered threading hole 55 formed by the threading guide assembly 5 in the device of the present invention coincides with the axis of the clamp jaw 56 , and the axis of the terminal box through hole 73 coincides with the terminal push rod 12 . When working, first put a certain number of term...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com