A fully automatic both ends crimping and inserting machine

An insertion machine and fully automatic technology, which is applied in the assembly/disassembly of contacts, electrical components, circuits, etc., can solve the problems of unstable finished product quality, high dependence on workers, and low production efficiency, achieving a high degree of automation and reducing Production cost and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

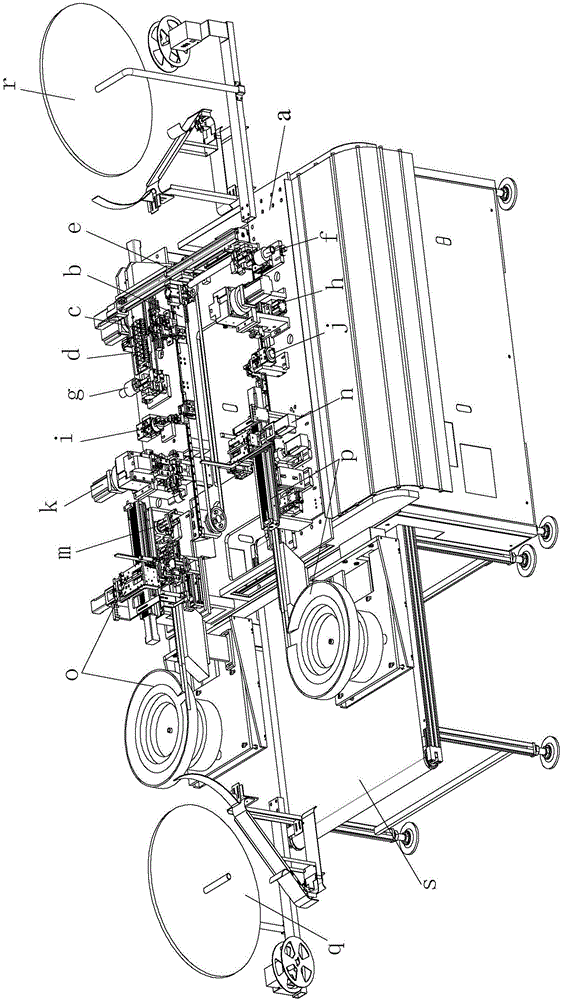

[0063] Such as Figure 1 to Figure 11 As shown, a fully automatic two-end crimping and inserting machine of this embodiment includes a workbench a, on which:

[0064] The wire conveying mechanism b is used to convey the cut wire segment to the specified stroke, so that the mechanism at the relevant position can process the wire segment, and it is installed on the workbench a along the X-axis direction;

[0065] The wire cutter mechanism c is used to cut a single wire running through it to form a wire segment, which is located at the Y-axis rear edge side of the feed end of the wire conveying mechanism b;

[0066] Wire feeding mechanism, which includes a wire fixing device d for arranging the wire harness to be processed and a wire pulling device e ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com