Continuous production method of hot-and-dry noodles, and special production line

A production method and technology for hot-drying noodles, which can be applied in application, dough processing, baking, etc., can solve the problems of low production efficiency, high labor intensity, time-consuming and labor-intensive, etc., to improve production efficiency, ensure food hygiene, and ensure stable quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

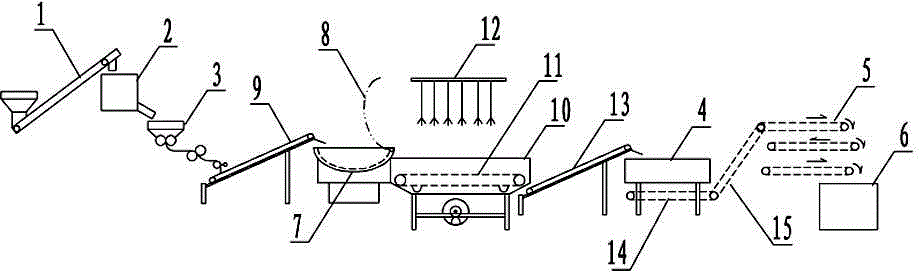

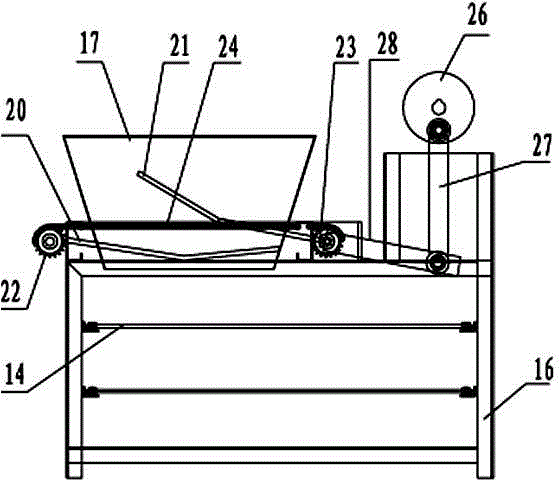

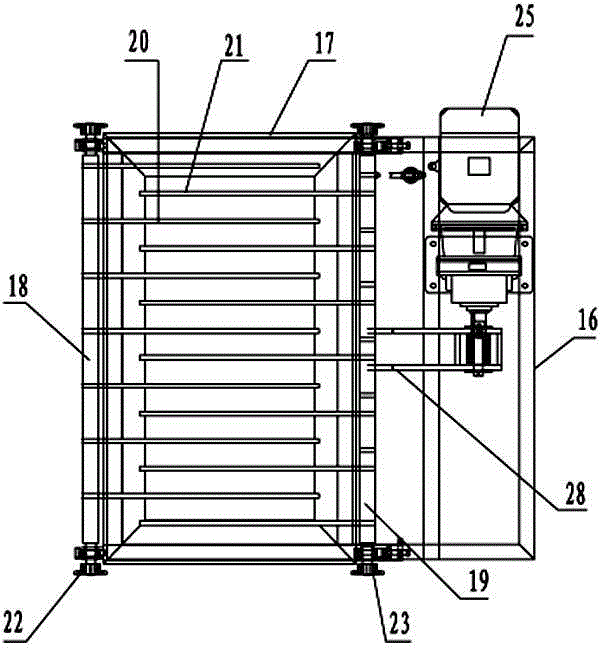

[0016] Such as figure 1 , 2 , 3, the special production line for the continuous production of hot-dry noodles according to the present invention includes a flour conveyor 1, a noodle mixing machine 2, a noodle rolling and shearing machine 3, a noodle curing pot, a noodle water cooler, and a noodle shaking machine 4. Noodle drying conveyor 5, packaging table 6; the outlet of flour conveyor 1 is connected with the inlet of noodle mixing machine 2, and the outlet of noodle mixing machine 2 is connected with the inlet of noodle rolling and shearing machine 3 connection; the noodle curing pot is composed of a pot body 7 with a heating chamber at the bottom and a bowl-shaped grate 8 hinged in the pot body 7; Connected together, the noodle water cooler is located on the turned-up side of the bowl-shaped grate 8, and the noodle water cooler is composed of a conveying mesh belt 11 arranged in the water receiving tank 10 and a spray water pipe 12 arranged above it; the conveying mesh b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com