Large-scale hot-dry noodle continuous production line

A hot-dry noodle and production line technology, which is applied in application, food preparation, food science, etc., can solve the problems of low production efficiency, time-consuming and labor-intensive work, and high labor intensity, and achieve the effects of improving production efficiency, ensuring food hygiene, and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

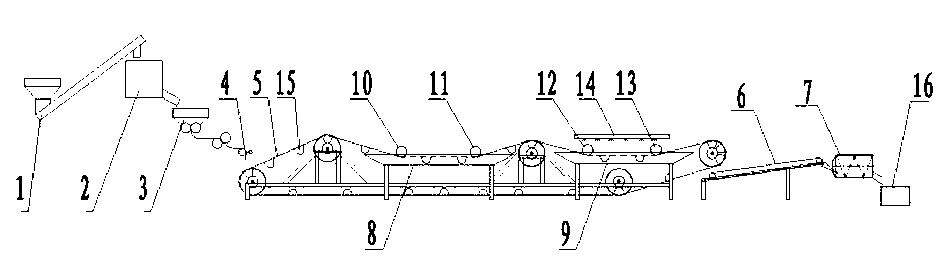

[0009] Such as figure 1 As shown, the large-scale hot-dried noodle continuous production line of the present invention includes a flour conveyor 1, the outlet of the flour conveyor 1 is connected with the inlet of the noodle mixing machine 2, and the outlet of the noodle mixing machine 2 It is connected with the feed port of the noodle rolling machine 3; a noodle shearing device 4 is arranged below the discharge opening of the noodle rolling machine 3, and the noodle shearing device 4 is located above the feed end of the net bag conveyor chain 5; the net bag conveyor chain 5 The discharge end is connected with the feeder 7 inlets through the conveyor belt 6; below the mesh bag conveyor chain 5, a boiling water pot 8 and a cold water pot 9 are successively arranged at intervals from the feed end to the discharge end, and the boiling water pot 8 and the cold water pot Guide rollers 10, 11, 12, 13 are respectively arranged along the longitudinal two ports of the pot 9, and the ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com