Cutter for food cutting machine

A cutting machine, food technology, applied in the direction of metal processing, etc., can solve the problems of difficult food hygiene, high production cost, low safety factor, etc., to achieve the effect of ensuring operation safety and food hygiene, reducing production costs and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

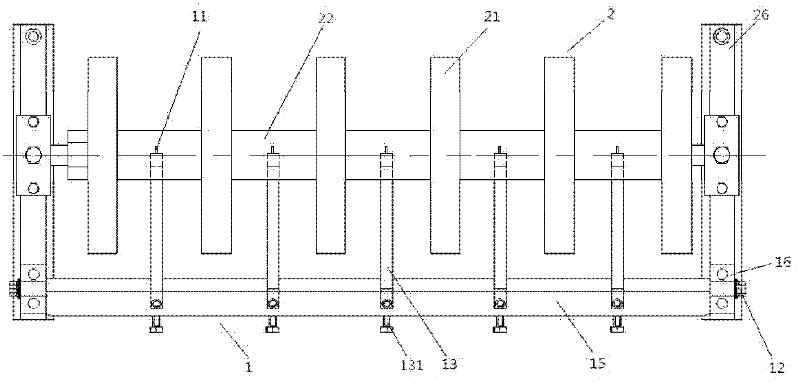

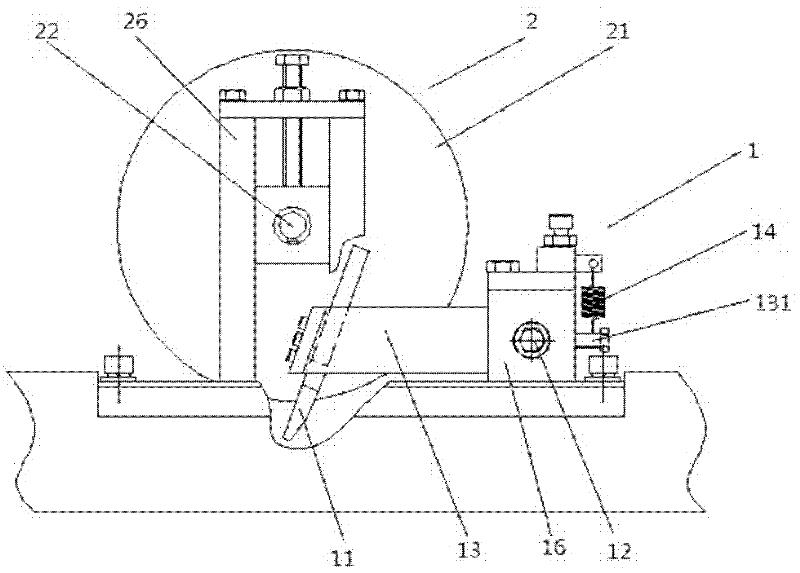

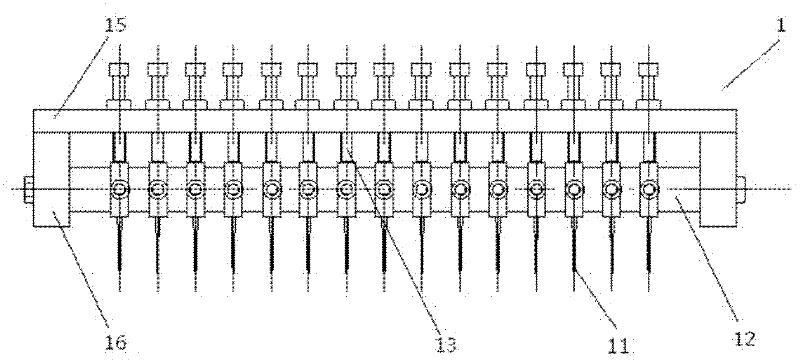

[0057] The difference between embodiment 2 and the cutter disclosed in embodiment 1 lies in the design of the pressure roller 2 . Figure 9 to Figure 14 , the connection setting of the pressure roller 2 is similar to that of the cutter 1.

[0058] The fixed connection between the cutter bracket 16 and the pressure wheel bracket 26 is such that the pressure wheel pieces 21 are arranged correspondingly at intervals between a plurality of the blades 11, and only one piece of the blade 11 is spaced between the blades 11. Describe the pressure wheel sheet 21.

[0059] When the knife is set on the cutting machine of the food cutting line, when the food advances to the position where the knife is set, the pressure wheel 2 presses the food due to the elastic force applied by the second spring 24, and at the same time because the pressure wheel 2 It can freely rotate around the third rotating shaft 27, so that the food can continue to move forward without being affected by the pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com