Multi-level tobacco leaf module threshing and re-baking feeding processing method

A processing method and a technology for threshing and redrying, which are applied in the fields of tobacco, tobacco preparation, application, etc., can solve problems such as lack of refined control process, and achieve the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The weight of each batch of the leaf threshing and redrying production line in this embodiment is 12000kg, and there are 4 leaf laying platforms in total, and a certain module A is taken as an example.

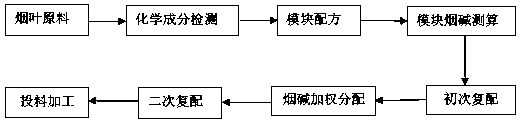

[0027] A method for threshing and redrying secondary compound feeding processing based on multi-level tobacco leaf module formula, specifically comprising the following steps:

[0028] According to the number of leaf-laying platforms, it is divided into main matching platform and auxiliary matching platform. If there are 4 leaf-laying tables, 3 leaf-laying tables are used as the main matching table, and the fourth one is used as the auxiliary matching table, which is used for blending that cannot evenly distribute cigarette packs.

[0029] Module A contains a, b, c, d, e, f, g, h, I, j, a total of 10 single-grade tobacco leaves, and their respective proportions are 2%, 4%, 24%, 9%, and 12%. , 23%, 13%, 4%, 7%, 2%, the nicotine content of each single-grade tobacco leaf ...

Embodiment 2

[0036]In this embodiment, the weight of each batch of the threshing and redrying production line is 12000 kg, and there are 4 leaf laying platforms in total, and a certain module B is taken as an example.

[0037] It is basically the same as Example 1, and the similarity is not described, and the difference is:

[0038] Module B contains 1#, 2#, 3#, 4#, 5#, 6#...20#, a total of 20 single-grade tobacco leaves, and the respective proportions are 2.0%, 3.0%, 3.0% , 3.0%, 4.0%, 5.0%, 2.0%, 2.5%, 3.0%, 3.5%, 2.5%, 7.5%, 5.0%, 12.0%, 3.0%, 5.0%, 4.0%, 22.0%, 4.0%, 3.5 %.

[0039] After testing, the nicotine content of each single-grade tobacco leaf is 3, 2.5, 3, 2.5, 4, 2.5, 3, 3, 2.8, 2, 2.1, 2.4, 2.2, 3.3, 2.8, 2.6, 3, 2.9, 3.2, 2.5. The theoretical value of the nicotine content of module B is calculated to be 2.80. The number of packs of cigarettes allocated to each leaf laying table in the initial configuration is 1, 2, 2, 2, 2, 3, 1, 2, 2, 2, 2, 5, 3, 7, 2, 3, 2, 13 , 2, 2...

Embodiment 3

[0041] The weight of each batch of the leaf threshing and redrying production line in this embodiment is 12000kg, and there are 4 leaf laying platforms in total, and a certain module C is taken as an example.

[0042] It is basically the same as Example 1, and the similarity is not described, and the difference is:

[0043] Module C contains 1#, 2#, 3#, 4#, 5#, 6#...30#, a total of 30 single-grade tobacco leaves, and the respective proportions are 2.0%, 3.0%, 4.0% , 3.0%, 4.0%, 3.0%, 2.0%, 2.0%, 3.0%, 2.0%, 2.5%, 2.5%, 4.0%, 6.0%, 3.0%, 5.0%, 4.0%, 8.0%, 2.0%, 2.5 %, 2.0%, 2.0%, 3.0%, 4.0%, 2.5%, 2.8%, 2.8%, 4.5%, 3.4%, 5.5%. After testing, the nicotine content of each single-grade tobacco leaf is 3, 2.5, 3.4, 2.5, 4, 2.5, 3, 3, 2.8, 2, 2.1, 2.4, 2.2, 3, 2.8, 2.6, 3, 2.9, 3.2, 2.5, 1.9, 1.8, 2.2, 3.3, 2.1, 2.1, 1.9, 2.5, 2.1, 1.9. The theoretical value of the nicotine content of module C is calculated to be 2.62.

[0044] The number of packs of cigarettes allocated to each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com