Parallel machine tool capable of realizing five-axis processing

A parallel, machine tool technology, applied in metal processing mechanical parts, metal processing equipment, manipulators, etc., can solve the problems of low end cutting accuracy, poor dynamic performance, large motion inertia, etc., to reduce the cost of machine tools, high rigidity, and mechanism volume. bigger effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

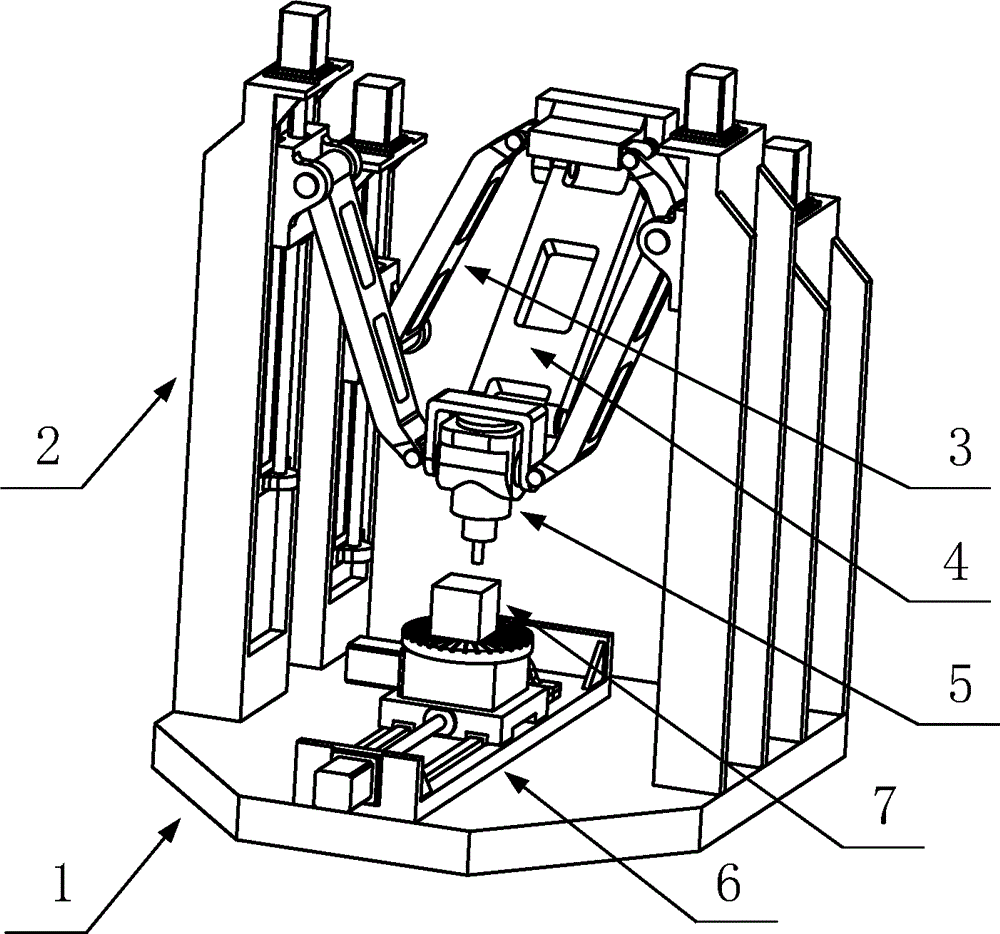

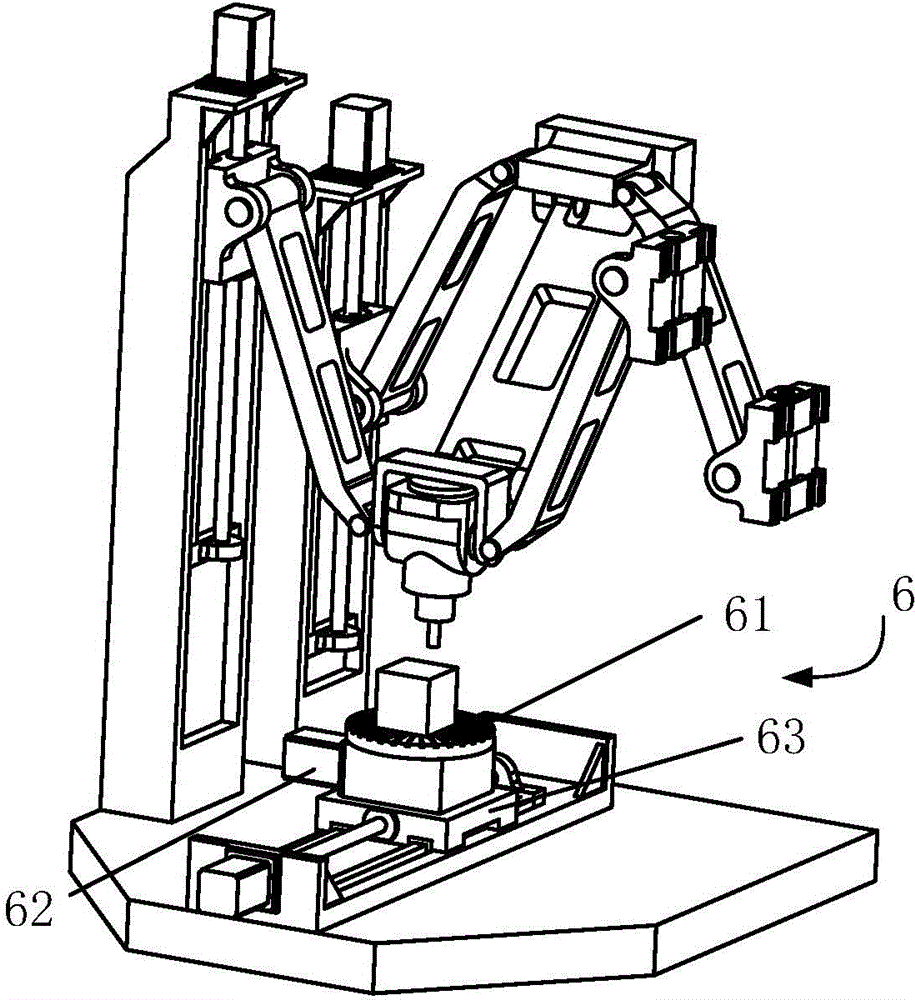

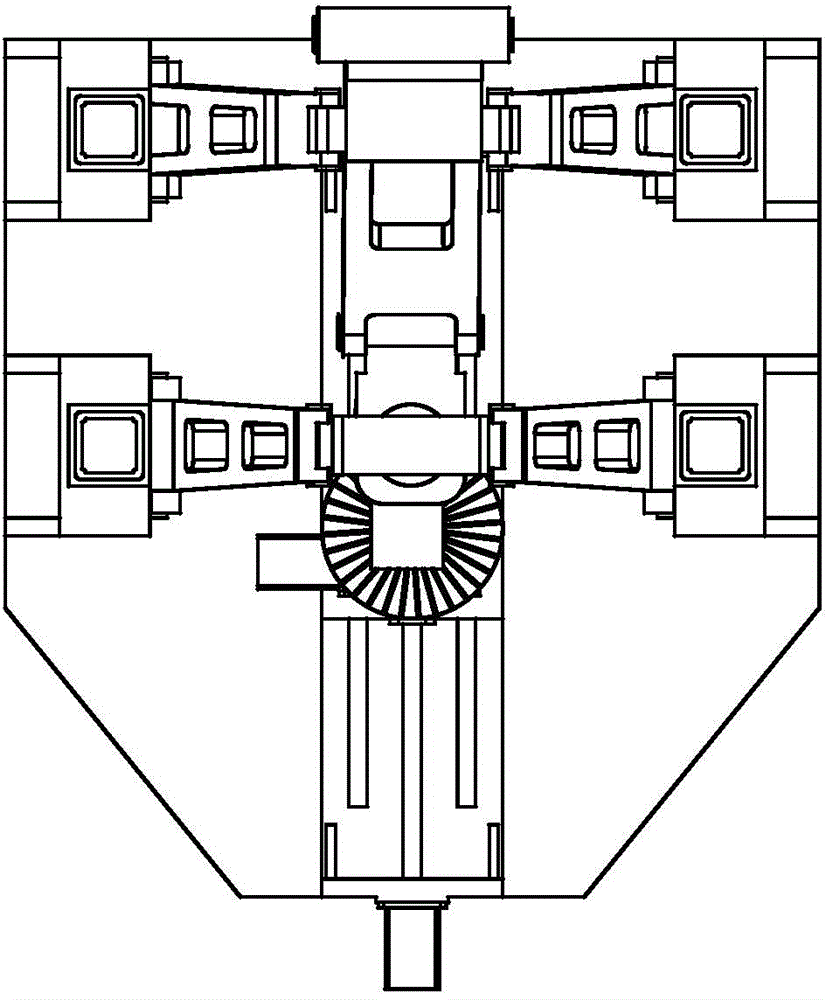

[0026] see Figure 1 to Figure 6 , the present invention proposes a parallel CNC machine tool capable of five-axis machining, including a bed 1, a four-degree-of-freedom space parallel closed-loop mechanism, an end effector 5, and a working platform 6; the four-degree-of-freedom space parallel closed-loop mechanism includes a front Parallel mechanism 2, rear parallel mechanism 3 and a set of series rod groups.

[0027] The front parallel mechanism 2 and the rear parallel mechanism 3 have the same structure, and both include two columns arranged on the left and right and a moving platform, the two columns are fixed on the bed 1, and the moving platform is arranged on Between the two columns, each of the two columns is connected to the moving platform through a chain, and the branch chain includes a set of linear drive device I and a transmission link 25, and the transmission link 25 is set There are power input end and platform connection end;

[0028] The left and right side...

Embodiment 2

[0039] see Figure 7 , the difference between this embodiment and embodiment 1 is that the structure of the front parallel mechanism 2 and the rear parallel mechanism 3 are different, but the difference is very small, only the hinges VI and VII in the embodiment 1 are transformed into A hinge VIII.

[0040] In summary, the present invention discloses a parallel machine tool capable of five-axis machining, including a bed, two sets of front and rear parallel mechanisms, a series connecting rod group, a two-degree-of-freedom workbench, and an end effector; the front and rear two The sets of parallel mechanisms have basically the same structure, including two columns symmetrically arranged, a moving platform, and two branch chains connecting the column and the moving platform, wherein the two branch chains have the same structural form, and each branch Each chain has a linear drive unit; the moving platforms of the front and rear parallel mechanisms are connected to the series l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com