Device and processing method for fine processing of reinforcing cage with arbitrary pile diameter

A technology of fine processing and processing method, applied in the processing of building materials, construction, building structure, etc., can solve the problems of complicated operation, the appearance and processing quality of the steel cage are difficult to meet the design requirements, and the fine processing of the steel cage cannot be realized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

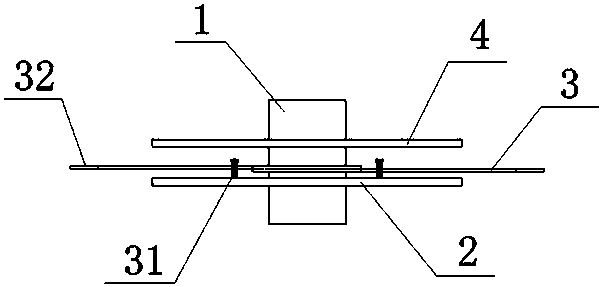

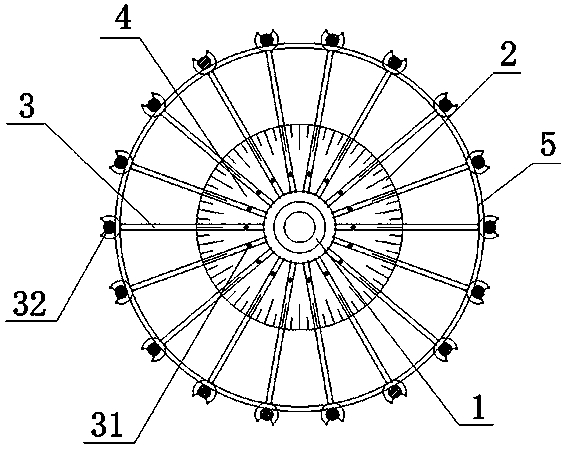

[0020] Such as figure 1 As shown, it is a front view of a fine processing device for a steel cage with any pile diameter according to the present invention, which includes a central shaft 1, an angle divider 2, a telescopic rotating support rod 3 and a positioning chuck 4, and the central shaft 1 is a steel pipe with a length of 200mm, an outer diameter of φ100mm, and a wall thickness of 10mm, with external threads on its outer circle; the angle divider 2 is a stainless steel disc with a diameter of φ500mm, and the disc is marked with 0° to 360° The scale line is fixed with the central axis as a whole, and is used for the angular positioning of the main reinforcement of the reinforcement cage.

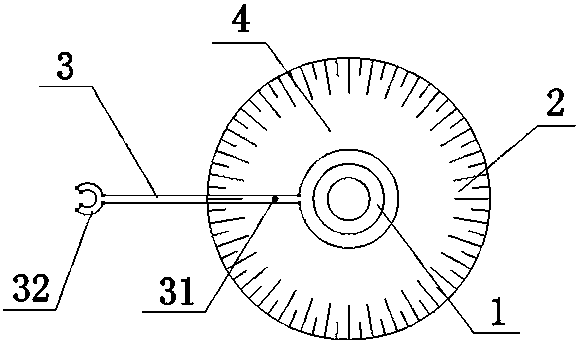

[0021] Such as figure 2 As shown, it is a top view of a fine processing device for a steel cage with any pile diameter according to the present invention. The telescopic rotating support rod 3 can rotate along the central axis 1, and the angle of the main reinforcement of the steel c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com