Low-flow speed steam nozzle for processing tobacco

A steam nozzle and low flow rate technology, applied in tobacco, tobacco preparation, application, etc., can solve the problems of inconsistency in receiving steam heat energy of smoke sheets, ineffective control of tobacco chemical composition changes, poor uniformity, etc., and achieve reliable performance, structure Simple, low-speed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

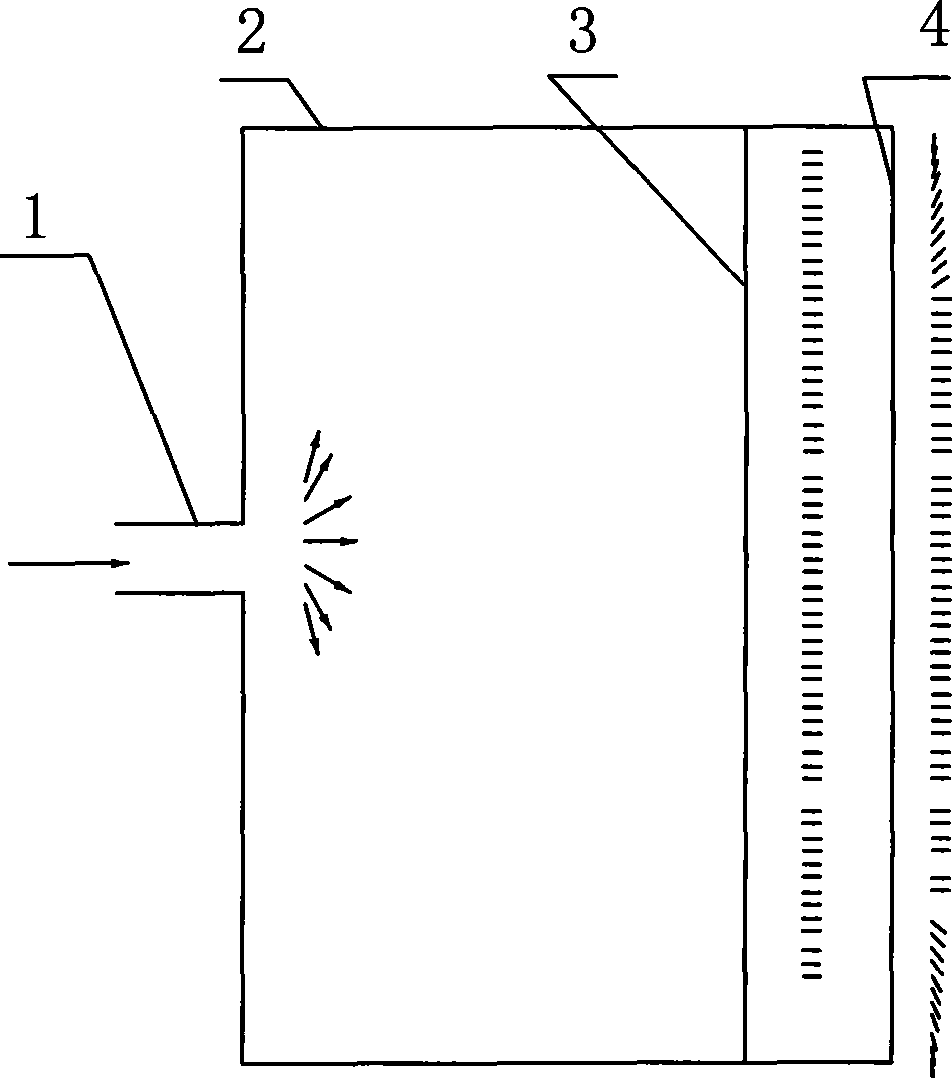

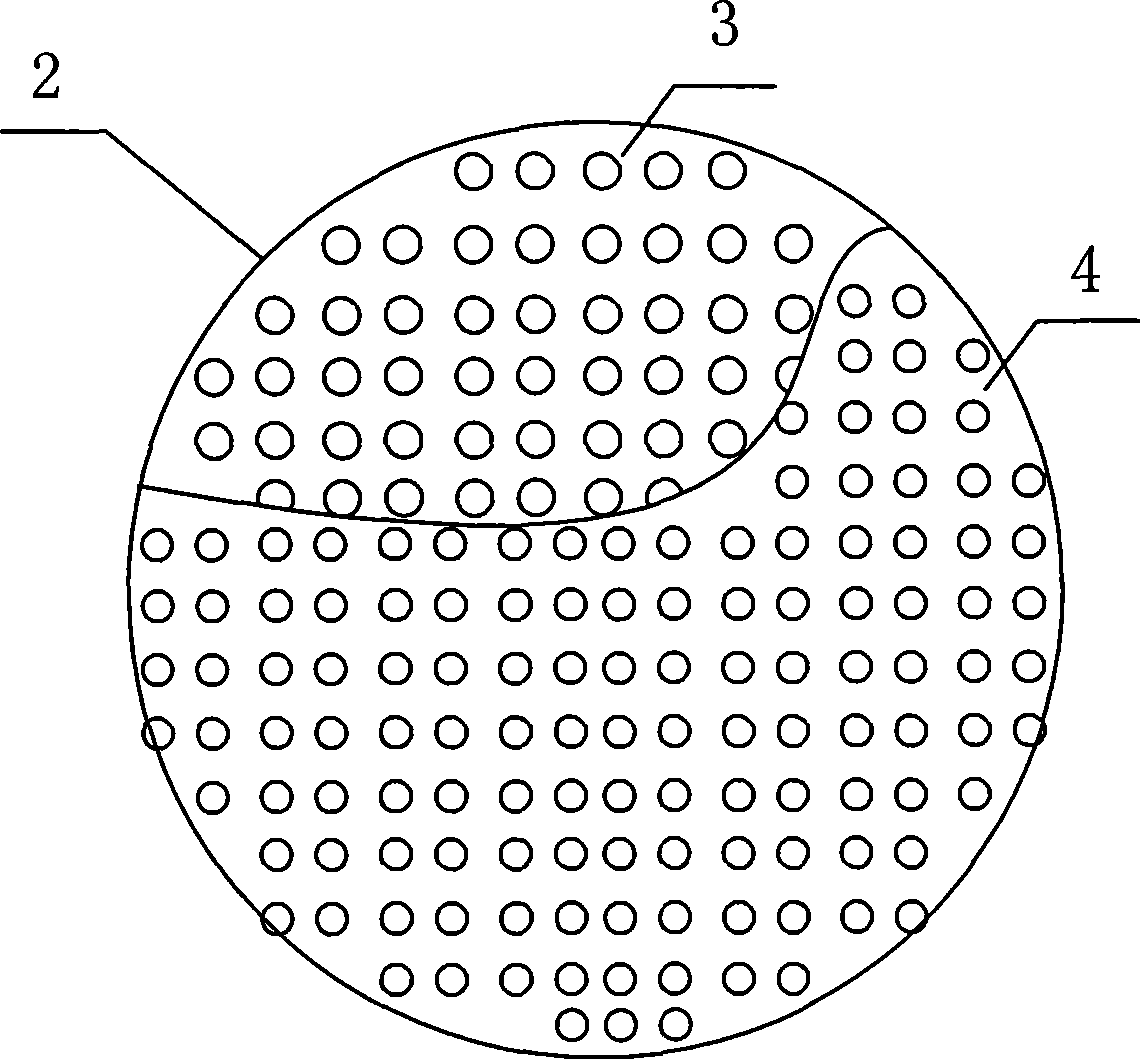

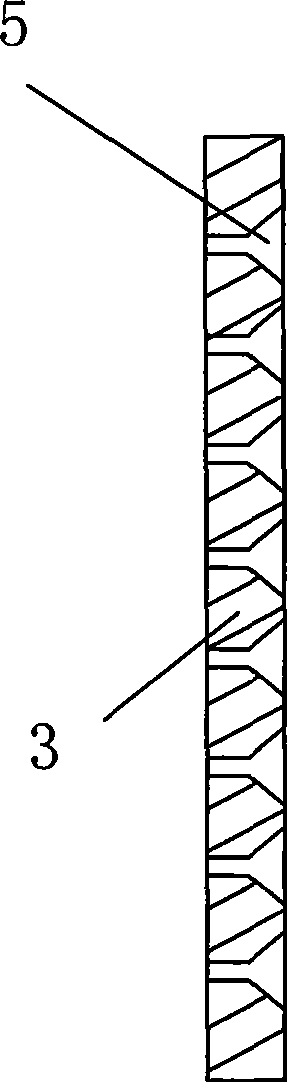

[0013] see figure 1 , figure 2 and image 3 , the steam pipe 1 is connected with a straight nozzle 2 whose diameter is several times larger than that of the steam pipe 1, and the outer layer of the outlet of the straight nozzle 2 is provided with a secondary mesh baffle 4, and the inner layer is provided with a first-stage Mesh type baffle 3, the mesh aperture on the primary mesh type baffle 3 is greater than the mesh aperture on the secondary mesh type baffle 4, the mesh on the secondary mesh type baffle 4 The number of holes is greater than the number of meshes on the first-stage mesh baffle 3, and the meshes on the first-stage mesh baffle 3 and the meshes on the second-stage mesh baffle 4 are all made of conical mesh. Hole 5.

[0014] see figure 1 , figure 2 and image 3 , the application of this device will form a hot steam field w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com