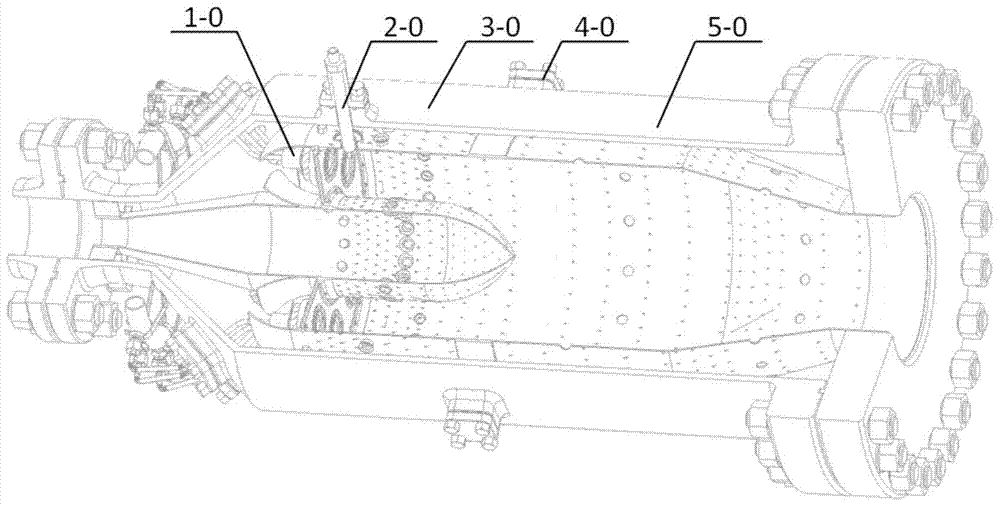

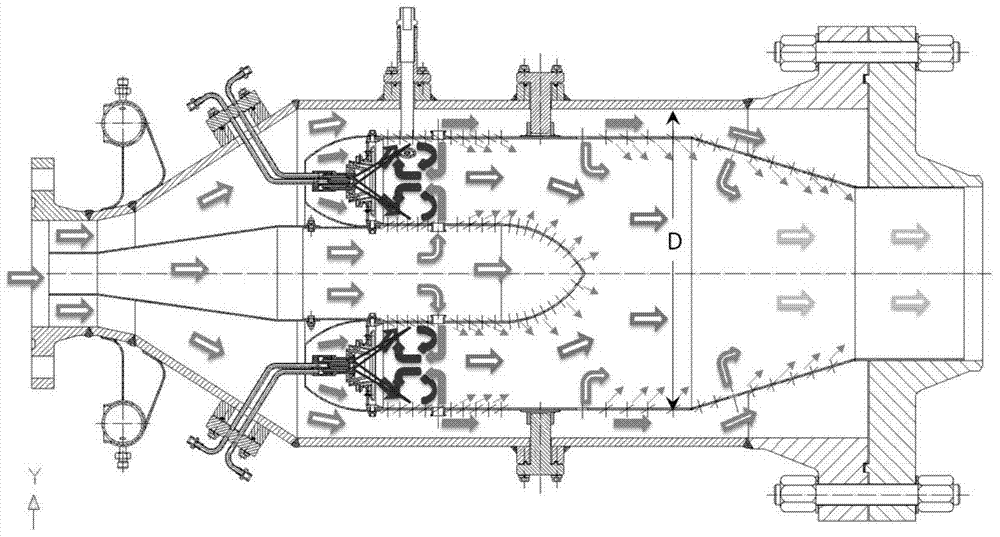

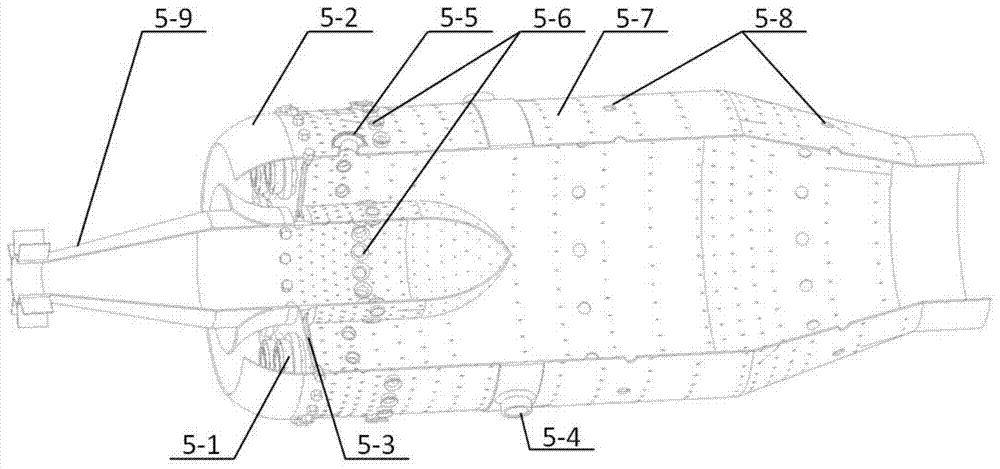

Annular combustion chamber fuel gas generator using alcohol as fuel

A technology of annular combustion chamber and gas generator, which is applied in the direction of burners, lighting and heating equipment, etc., can solve the problem of low operating cost and achieve the effect of high ignition reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following is a detailed description of the specific implementation of the patent of the present invention, giving the design idea and the calculation method of important structural dimensions. Those skilled in the field of aero-engine main combustion chamber design can reproduce the related products of this patent according to this method.

[0033] 1 design input

[0034] The gas generator design requires the following parameters to be known:

[0035] 1) Air flow: W a

[0036] 2) Air pressure: P a

[0037] 3) Inlet temperature: T in ≈288K

[0038] 4) Outlet temperature: T out ≈1100K

[0039] 2 Aerothermal Calculation

[0040] 1) Fuel flow W f

[0041] W f = W a L 0 α . . . 1

[0042] Among them: L0 =9 is the theoretical air volume

[0043...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com