Steel plate surface leveling and deburring device

A technology for surface flattening and steel plate, applied in the direction of grinding drive device, grinding machine, grinding machine parts, etc., can solve the problems of poor adjustability, low grinding and leveling efficiency, etc., to achieve complete deburring, excellent deburring effect, and sufficient grinding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

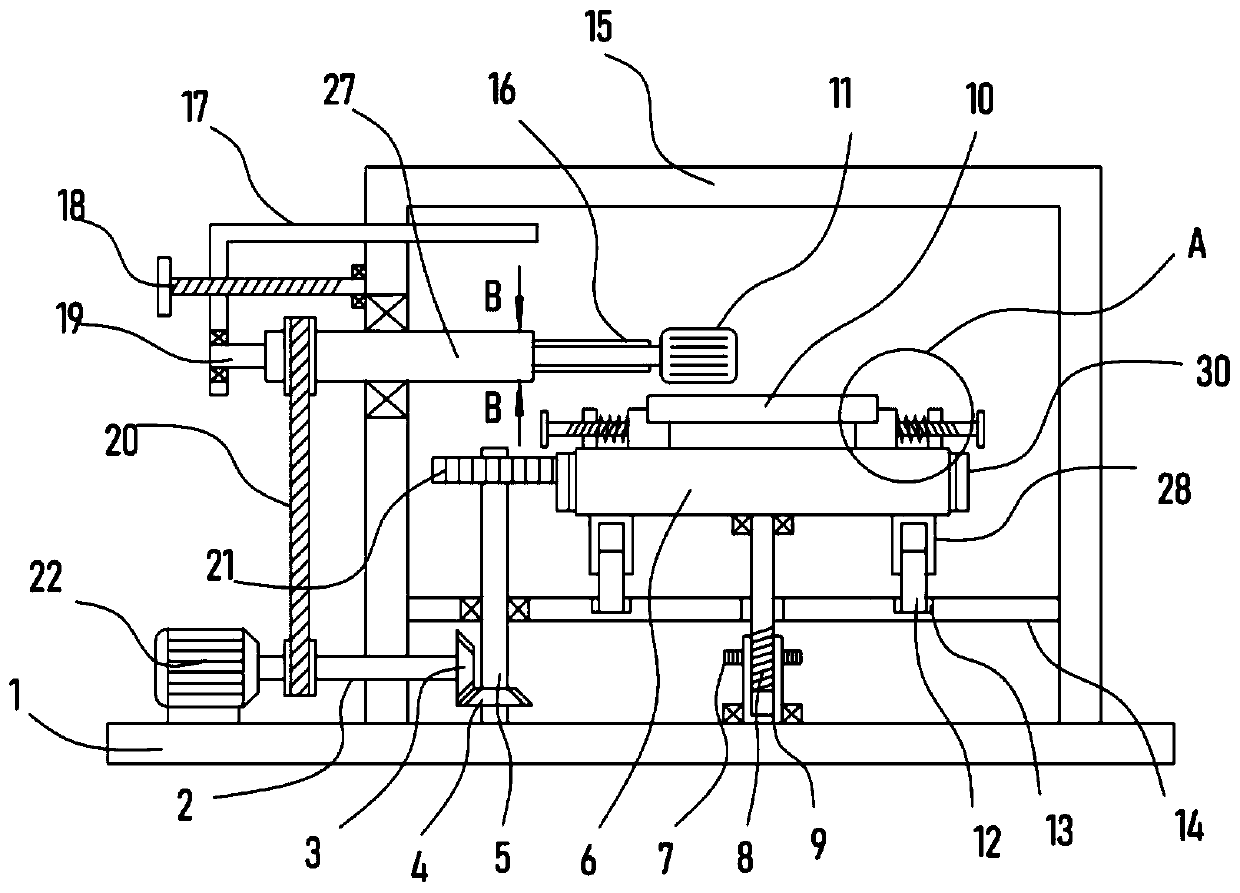

[0021] see Figure 1-3 , a steel plate surface leveling and deburring device, comprising a support base plate 1, a support frame 15 is fixed on the support base plate 1, a horizontal plate 14 is horizontally fixed on the support frame 15, and a turntable 6 is arranged on the horizontal plate 14 in a rotating manner. A clamping mechanism for clamping the steel plate 10 is installed.

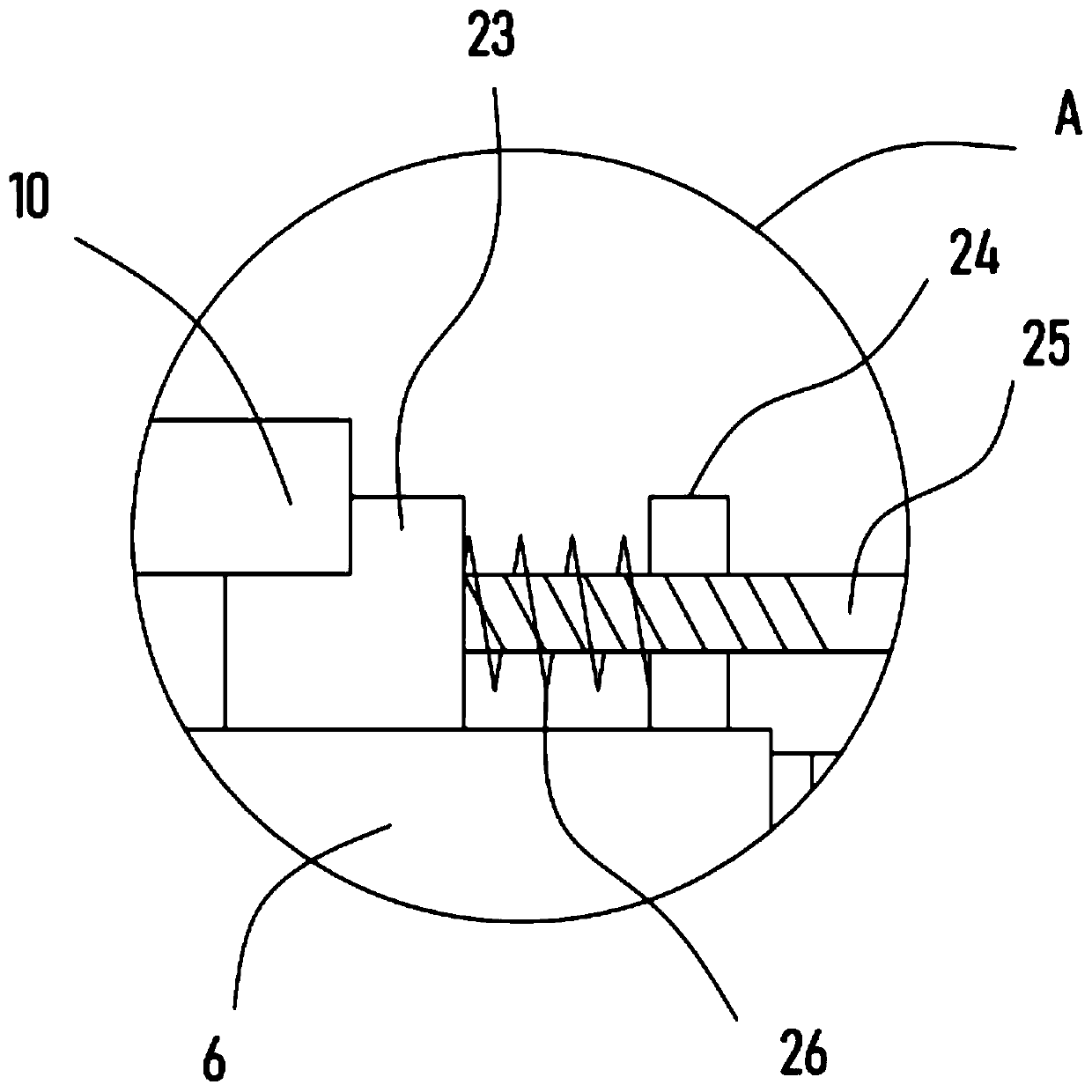

[0022] Before performing the deburring operation on the surface of the steel plate, the steel plate 10 is clamped and fixed on the turntable 6 by a clamping mechanism. A fixed plate 24 is fixed on the fixed plate 24, and the threaded connection on the fixed plate 24 is provided with a locking screw 25 that abuts against the block 23. Limiting spring 26.

[0023] The specific operation of the clamping process is as follows: place the steel plate 10 on the block 23, and push the block 23 to move toward each other by rotating the locking screw 25 to clamp and fix the steel plate 10 from both sides,...

Embodiment 2

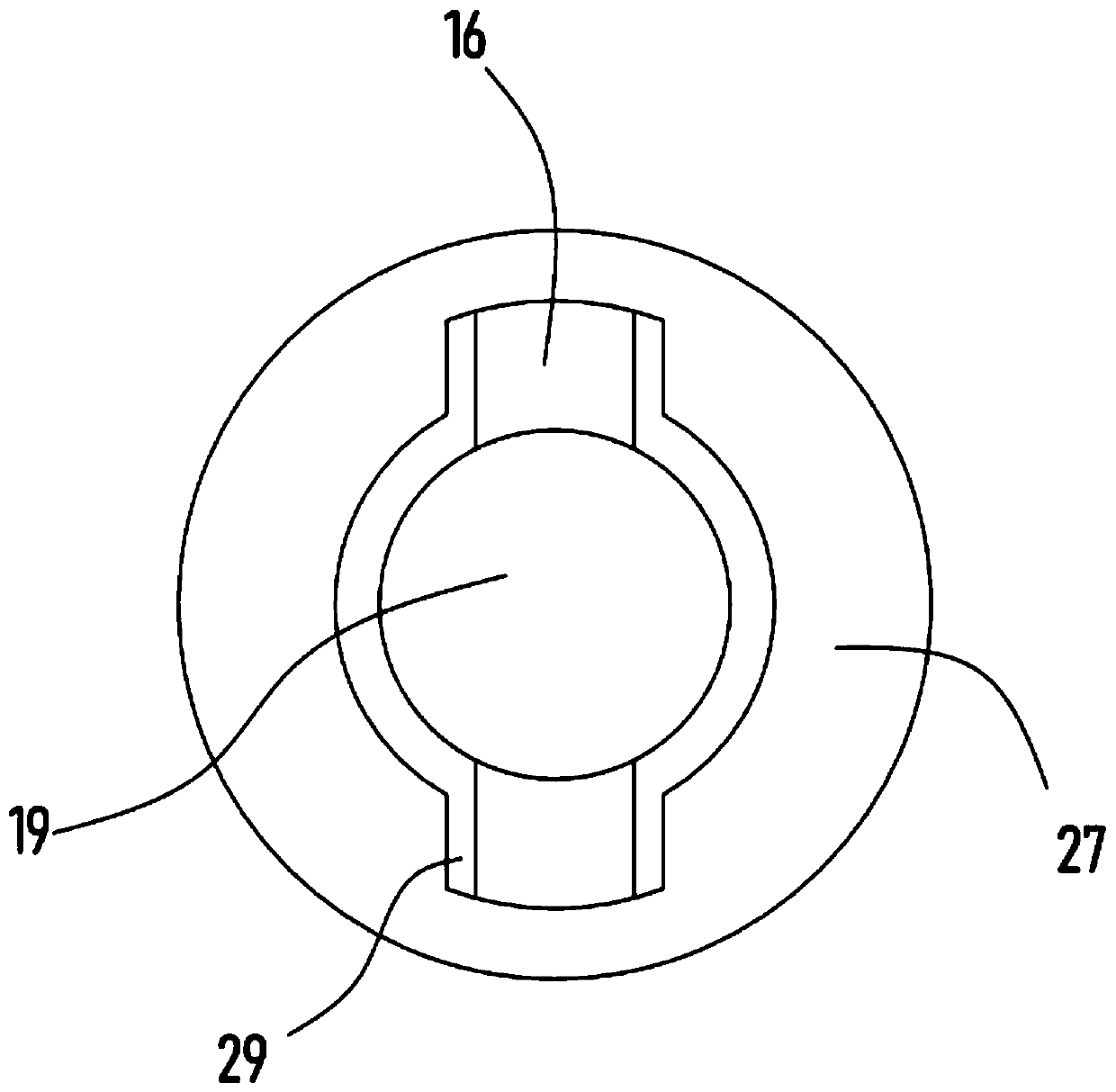

[0028] On the basis of Embodiment 1, the drive motor 22 that is connected to the output shaft and the transmission sleeve 27 through the pulley mechanism 20 is provided on the support base plate 1, and the output shaft of the drive motor 22 is coaxially fixed with the driving bevel gear 3, and the driven shaft 5 is sleeved with a driven bevel gear 4 meshing with the driving bevel gear 3 .

[0029] The driving motor 22 is used as the only power output of the device, and the driving motor 22 drives the driving shaft 2 to rotate, and the driving shaft 2 drives the transmission sleeve 27 to rotate through the pulley mechanism 20, and then realizes that the transmission column 19 drives the grinding head 11 to rotate, and at the same time, the driving The shaft 2 drives the driving bevel gear 3 to rotate, and the driving bevel gear 3 drives the driven shaft 5 to rotate through the driven bevel gear 4 meshing with it, and then realizes the meshing transmission between the driving gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com