A spike grinding device for processing agricultural spike harrows

A nail-tooth rake and nail-tooth technology, which is applied in the direction of manufacturing tools and other manufacturing equipment/tools, can solve the problems of uneven surface of the nail teeth and affect the use, and achieve the effect of improving the grinding effect, facilitating later use, and having a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

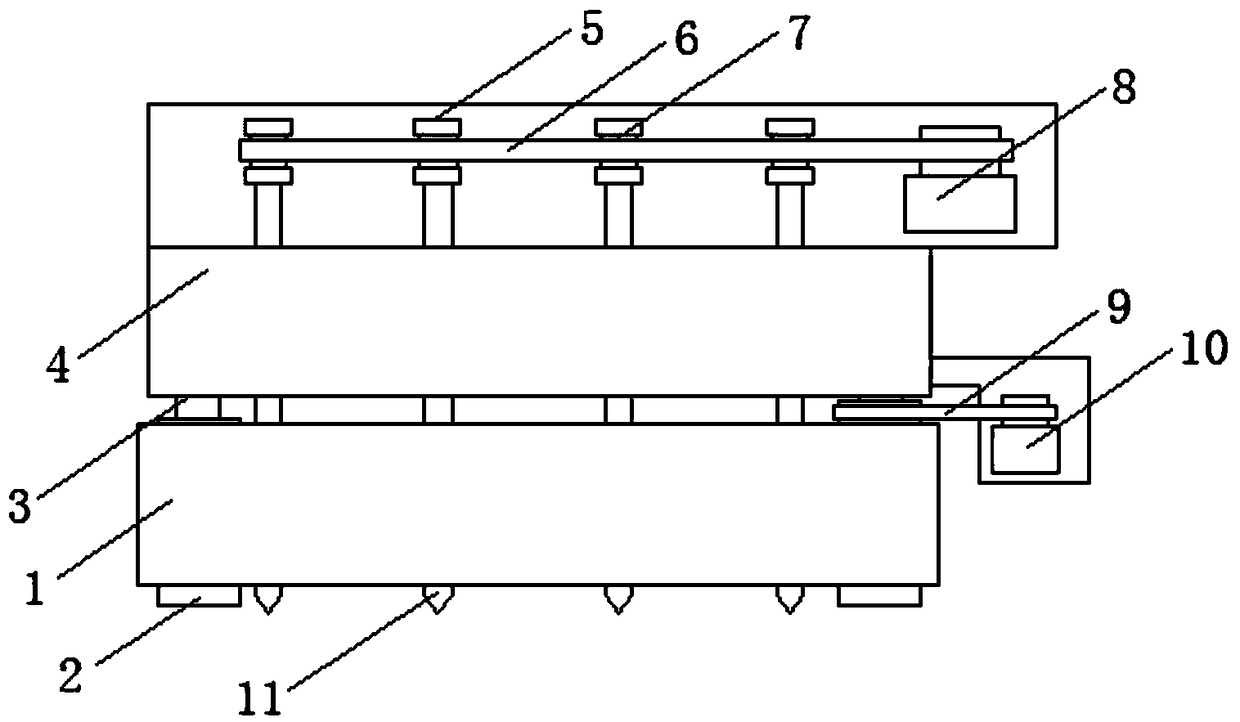

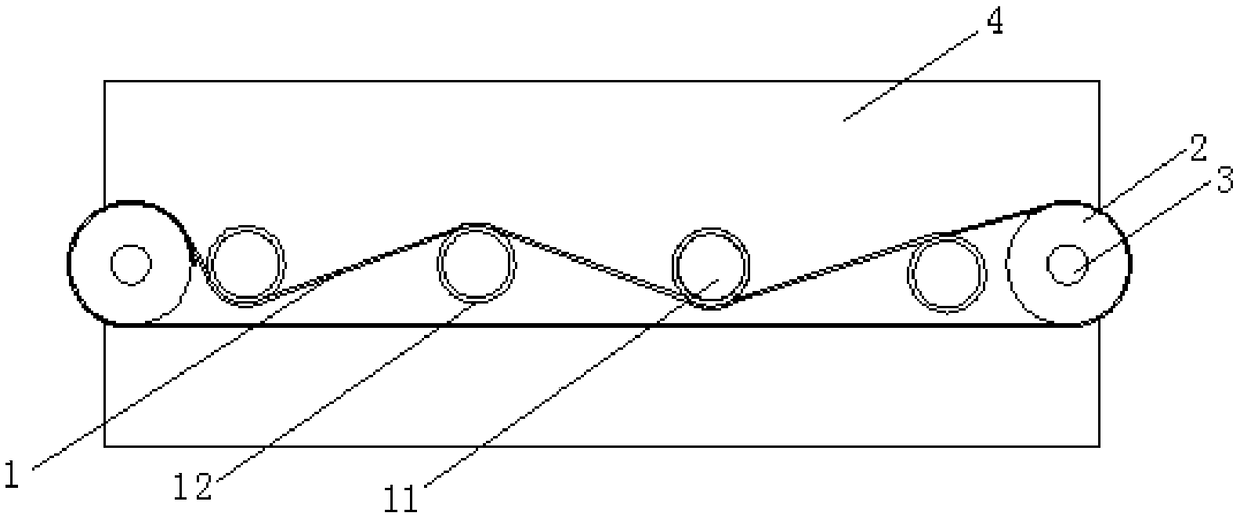

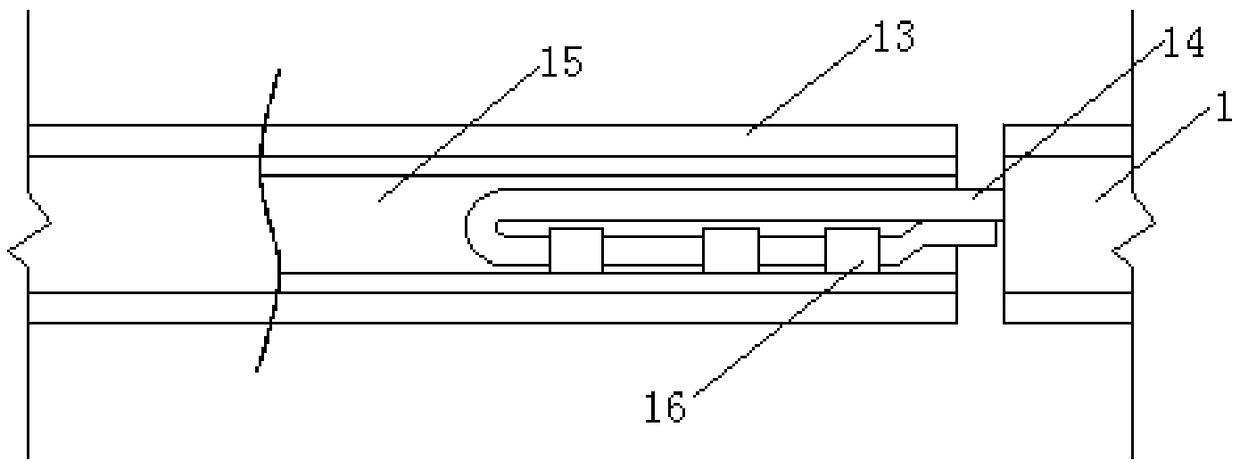

[0017] refer to Figure 1-3 , a nail tooth grinding device for processing agricultural nail tooth rakes, comprising a fixed seat 4, a plurality of sockets 12 are arranged horizontally and spaced apart in the fixed seat 4, and nail teeth 11 are inserted in each socket 12, The jacks 12 are all filled with buffer pads, and the buffer pads can fill up the jacks 12 after the nail teeth 11 are put into the jack 12, and limit the position of the nail teeth 11 to a certain extent. One end is set as a tip, and the end of the nail teeth 11 away from the tip is sleeved with a sleeve shaft 5, the surfaces of a plurality of sleeve shafts 5 are connected with the output shaft of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com