Shoe sole polishing device for leather shoe production

A technology for shoe soles and leather shoes, which is applied in grinding machines, footwear, applications, etc. It can solve the problems of low efficiency, time-consuming and labor-intensive, and poor manual grinding of shoe soles, and achieve high grinding efficiency and good results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

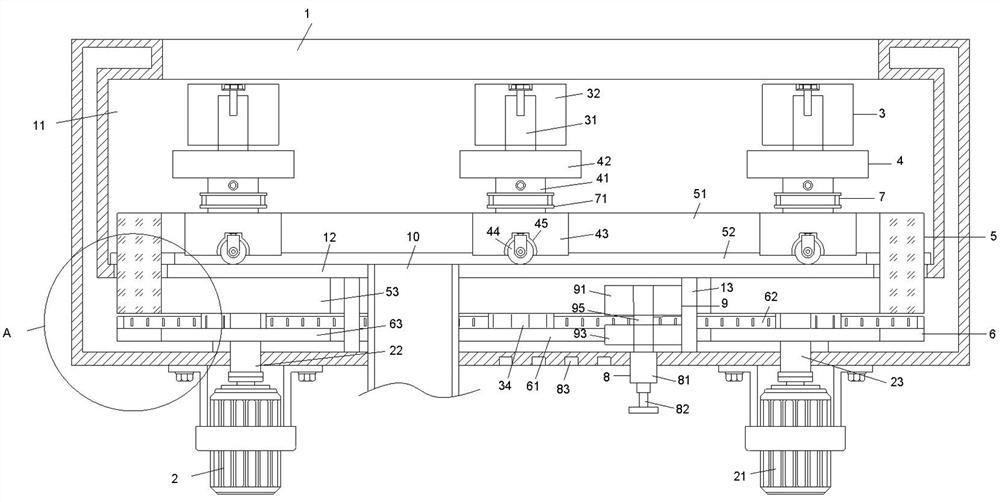

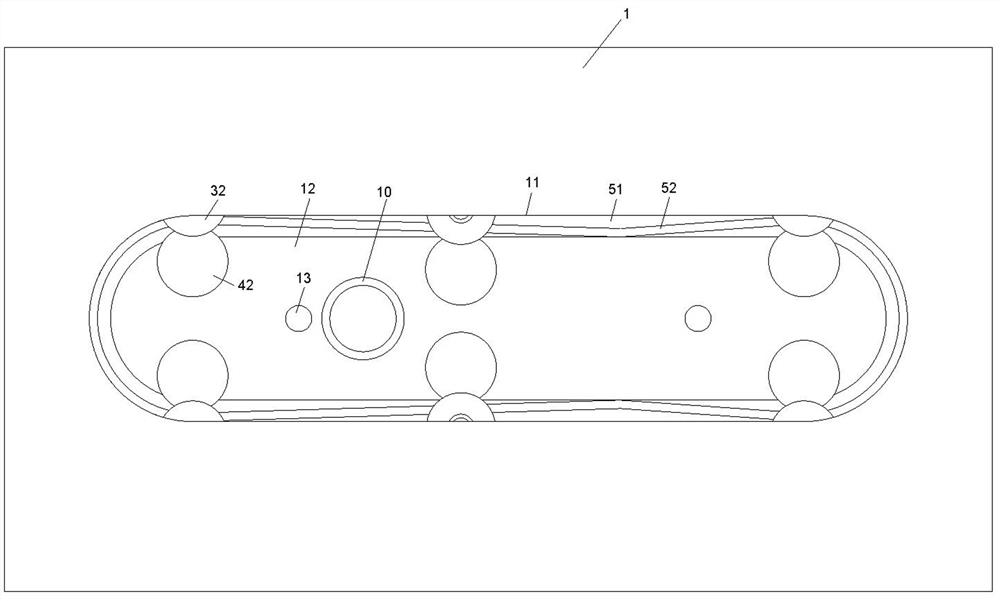

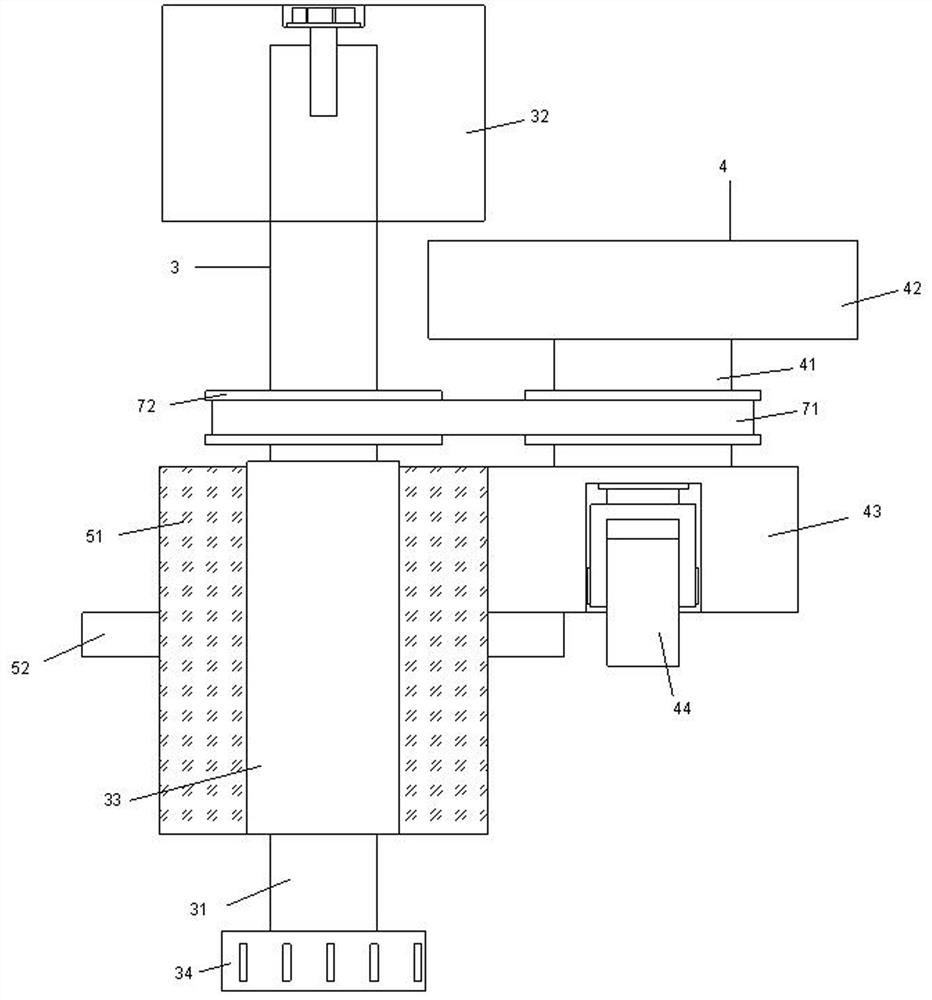

[0037] Example: such as Figure 1-6As shown, a shoe sole polishing device for leather shoes production according to the present invention includes a polishing box 1, the upper surface of the polishing box 1 is provided with a placement groove 11, and the inside of the placement groove 11 is provided with a sealing plate 12, and the sealing plate The bottom of 12 is fixedly connected with two support columns 13, and the bottom ends of the two support columns 13 are all fixedly connected with the bottom end of the inner wall of the placement groove 11, and a No. 1 transmission mechanism 5, the top of the No. 1 transmission mechanism 5 is provided with a side grinding mechanism 3, the inner ring of the No. 1 transmission mechanism 5 is provided with a bottom grinding mechanism 4, and the bottom of the No. 1 transmission mechanism 5 is provided with two The No. 2 transmission mechanism 6, the No. 2 transmission mechanism 6 is connected with the side grinding mechanism 3, the side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com