Machining device for automobile intercooler

A processing device and cooler technology, which is applied to machine tools, grinding drive devices, metal processing equipment, etc., which are suitable for grinding the edge of workpieces, can solve the problems of low grinding efficiency and insufficient comprehensiveness, and achieve the effect of efficient grinding treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

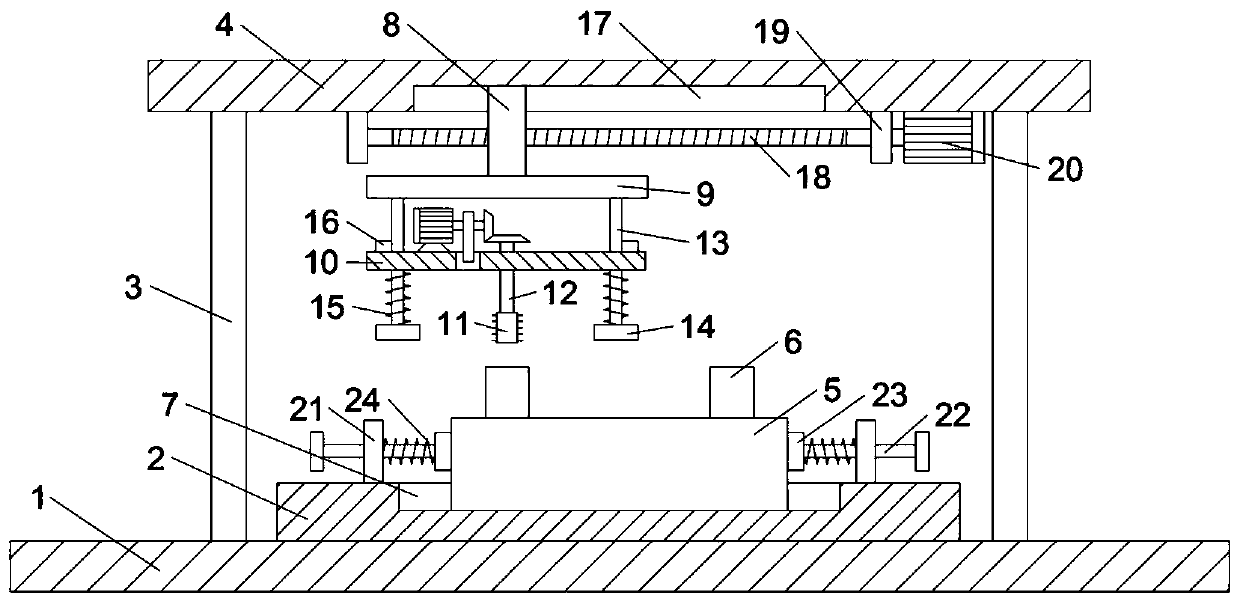

[0027] Reference attached figure 1 This embodiment provides a processing device for an automobile intercooler, which includes a workbench 2 and a polishing assembly, and the polishing assembly is rotatably arranged on one side of the workbench 2; wherein, the processing device is also include:

[0028] A driving mechanism for driving the polishing assembly to rotate; the driving mechanism is connected with the polishing assembly;

[0029] Reciprocating assembly, the reciprocating assembly is connected with the driving mechanism; when the driving mechanism drives the polishing assembly to rotate, the reciprocating assembly drives the polishing assembly to reciprocate linearly along the rotation axis of the polishing assembly;

[0030] The adjustment component is used to drive the polishing component to move linearly on one side of the worktable 2;

[0031] The positioning component is used for positioning and fixing the sample to be processed; the positioning component is set on the wo...

Embodiment 2

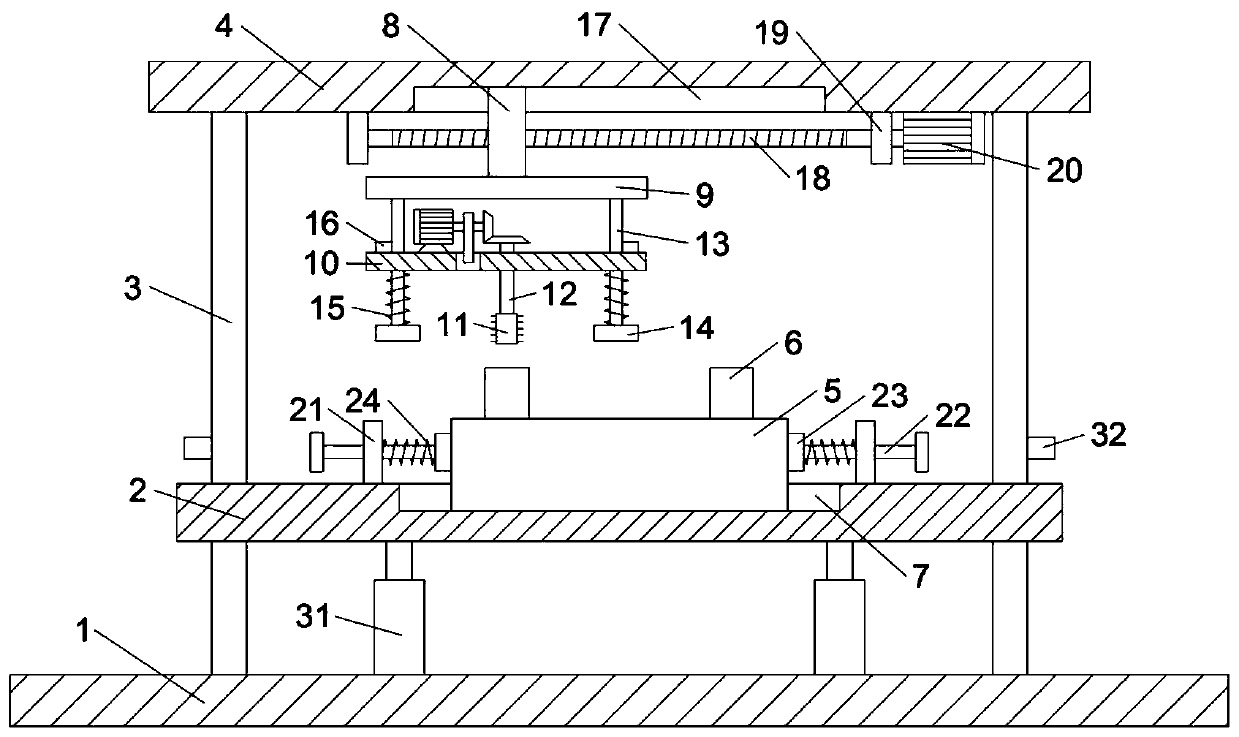

[0038] Reference attached image 3 This embodiment is an improvement on the basis of embodiment 1. Specifically, the workbench 2 is connected to the base 1 through at least one set of electric telescopic rods 31, and the electric telescopic rods 31 can adopt the common hydraulic pressure in the prior art. Cylinders, air cylinders, etc., but not limited to this; a pillar 3 is fixed on the base 1, the workbench 2 is in sliding fit with the pillar 3, and a second upper limit block 32 is also provided on the pillar 3. The worktable 2 can be driven to slide up and down through the electric telescopic rod 31, and when the worktable 2 slides to contact the second upper limit block 32, the grinding operation can be performed.

Embodiment 1-2

[0039] In combination with embodiment 1-2, when the processing device provided by the embodiment of the present invention is in use, first fix the intercooler 5 on the positioning groove 7 and make the oil pipe 6 of the intercooler 5 face upward; then, use an electric telescopic rod 31 makes the worktable 2 contact the second upper limit block 32; then, the first motor 20 drives the sanding roller 11 to move directly above the oil pipe 6; then, the starting motor 28 can simultaneously drive the sanding roller 11 to rotate and By reciprocating up and down, the inner wall of the oil pipe 6 can be polished efficiently.

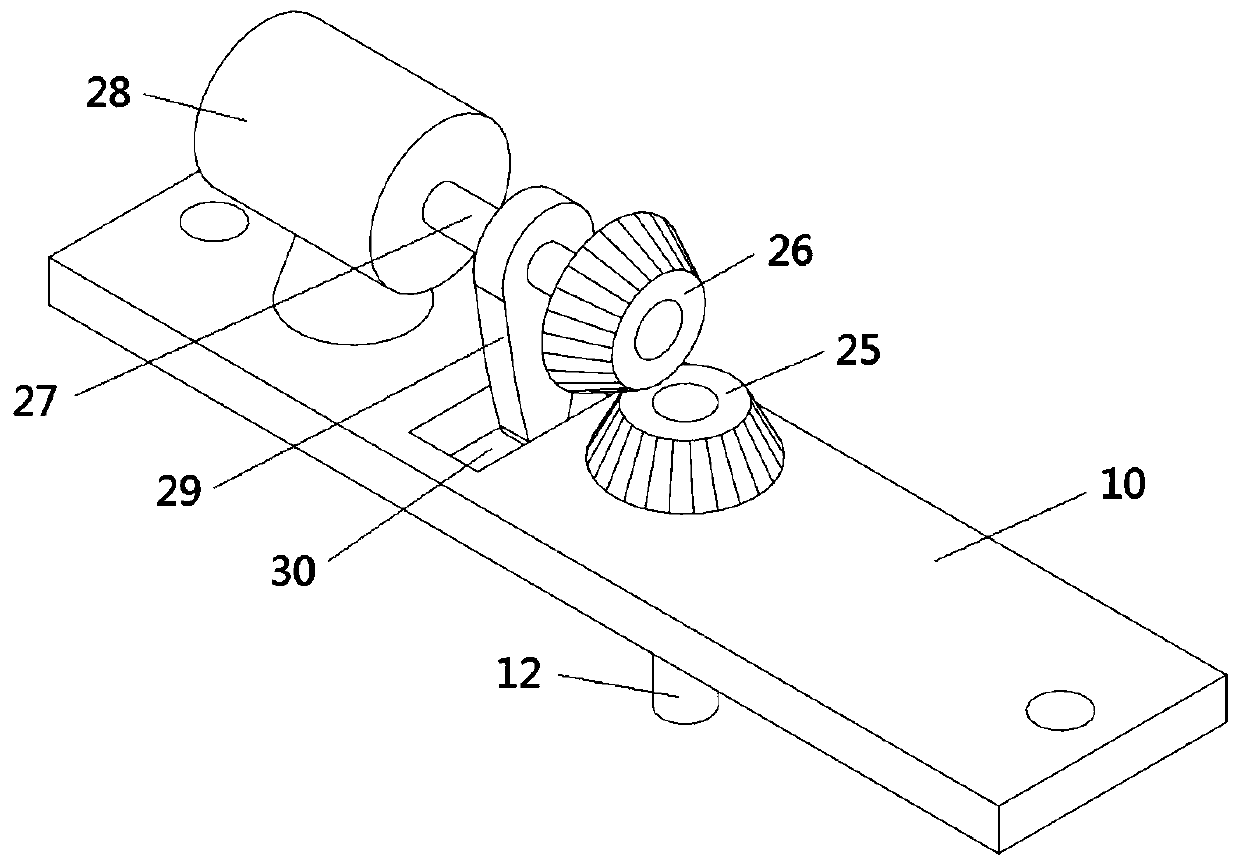

[0040] In summary, in the embodiment of the present invention, a slidable movable plate 10 is arranged on one side of the worktable 2 and a rotatable grinding roller 11 is arranged on the movable plate 10, so that the driven bevel gear 25 and The driving mechanism of the driving bevel gear 26 and the reciprocating assembly with the cam 29 and the first spring 15 sim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com