Five-axis polishing system

A rotating shaft and X-axis technology, which is applied in the field of five-axis grinding system, can solve the problems of increasing the labor burden of workers and the inapplicability of grinding machines, and achieve the effect of reducing labor burden, improving efficiency, and improving the efficiency of grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

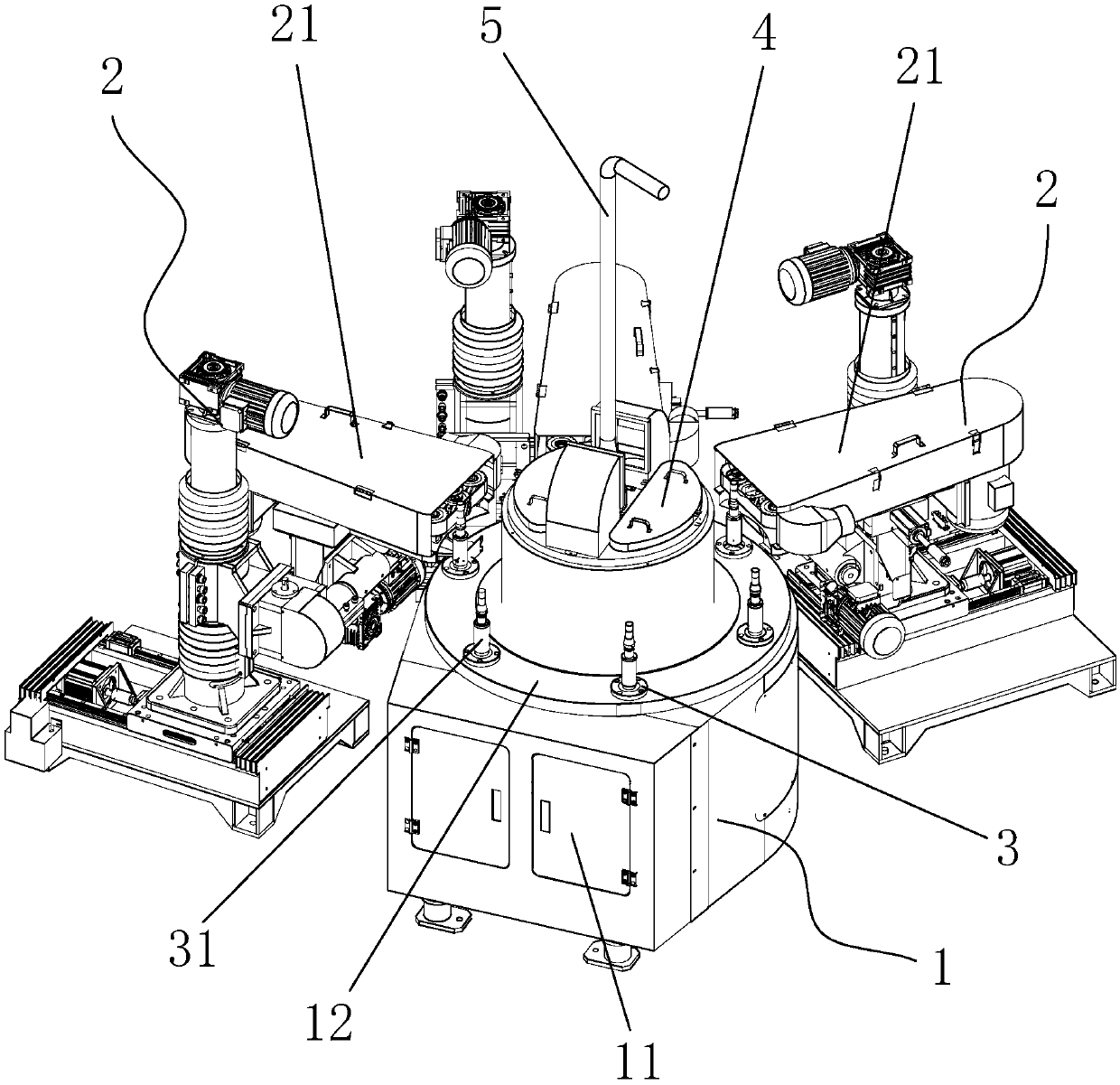

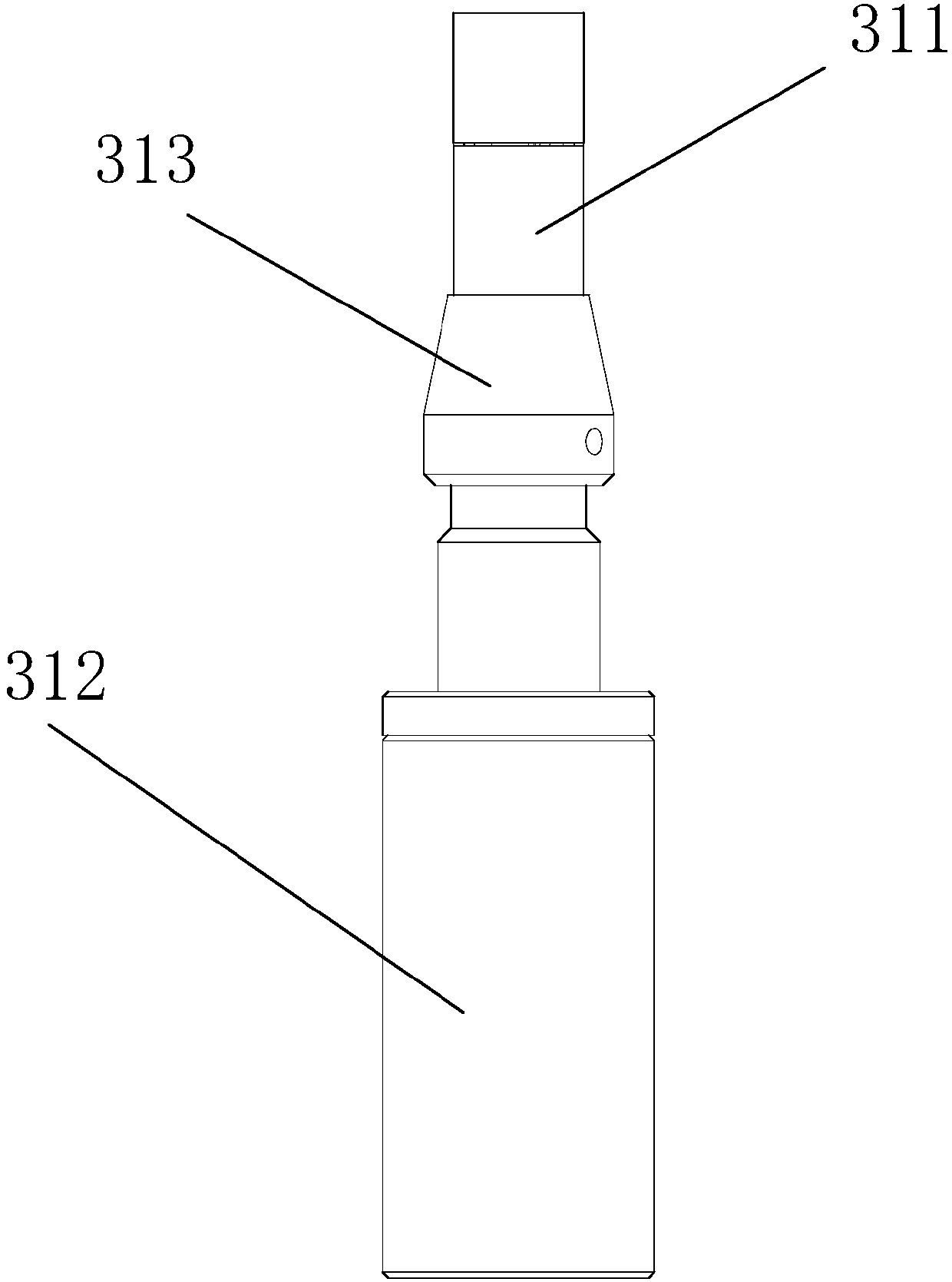

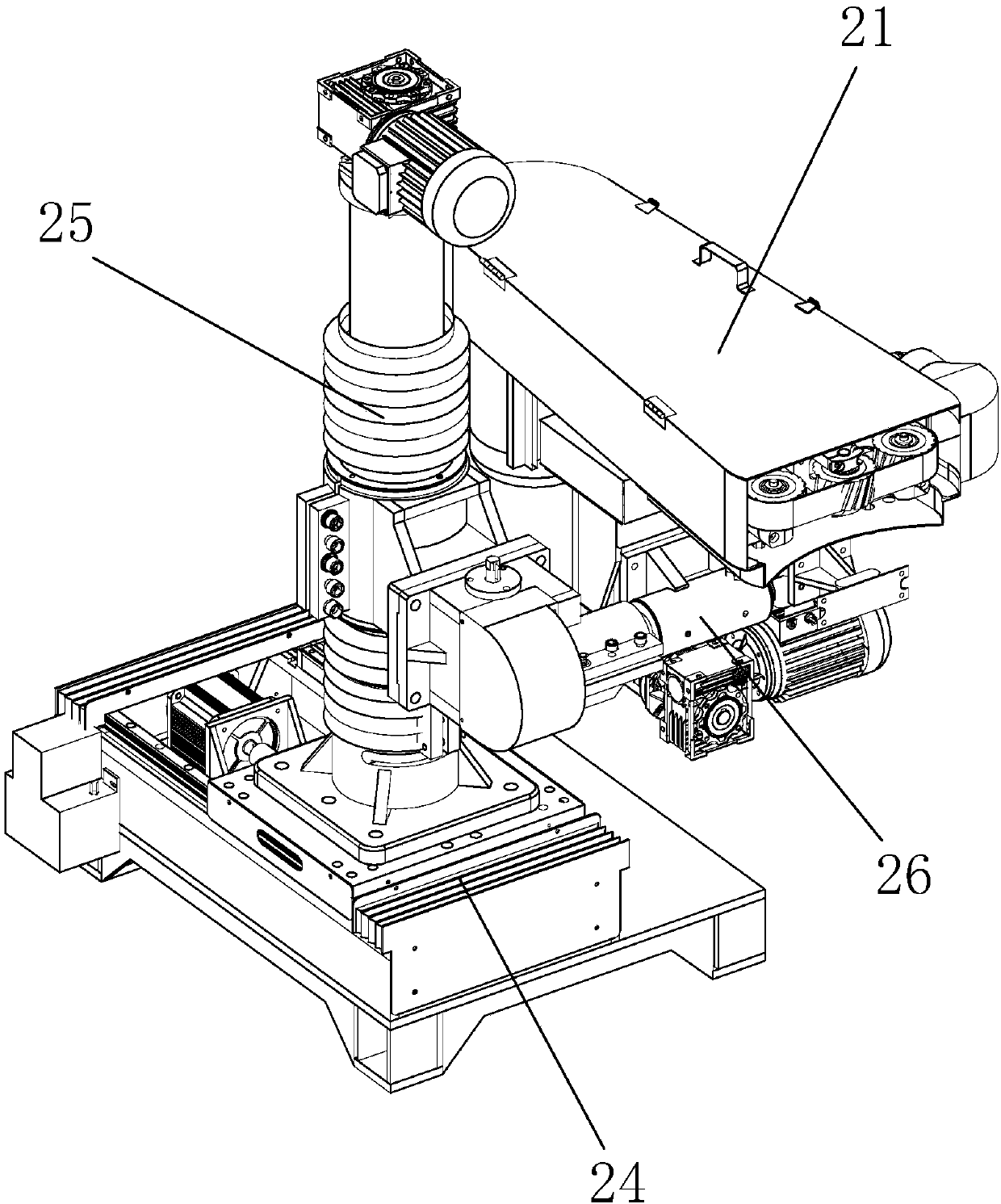

[0017] refer to Figure 1-Figure 4 , a five-axis grinding system of the present invention includes a main processing platform 1 for placing products and a grinding device 2 for grinding the products; the main processing platform 1 includes a central turntable 12 for driving the products to rotate, The processing disc 3 for placing products and the bottom box 11 for supporting the central turntable 12, the processing disc 3 is arranged on the edge of the central turntable 12; The S1 rotating shaft 31 and the S1 shaft motor 33 for driving the S1 rotating shaft 31 to rotate, the S1 rotating shaft 31 is vertically arranged on the center position of the processing disc 3, the S1 shaft motor 33 is arranged on the bottom of the processing disc 3 and is connected with the S1 rotating shaft 31 Connection; the grinding device 2 includes an abrasive belt head 21 and a moving mechanism that can drive the abrasive belt head 21 to move along four axial directions; the grinding device 2 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com