Multifunctional and flexible manipulator

A manipulator and multi-functional technology, which is applied in the field of intelligent robots, can solve the problems of low efficiency, low degree of freedom and can only complete a part, and it is difficult to accurately control the rotation angle of the flexible gripper, so as to reduce the labor burden and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

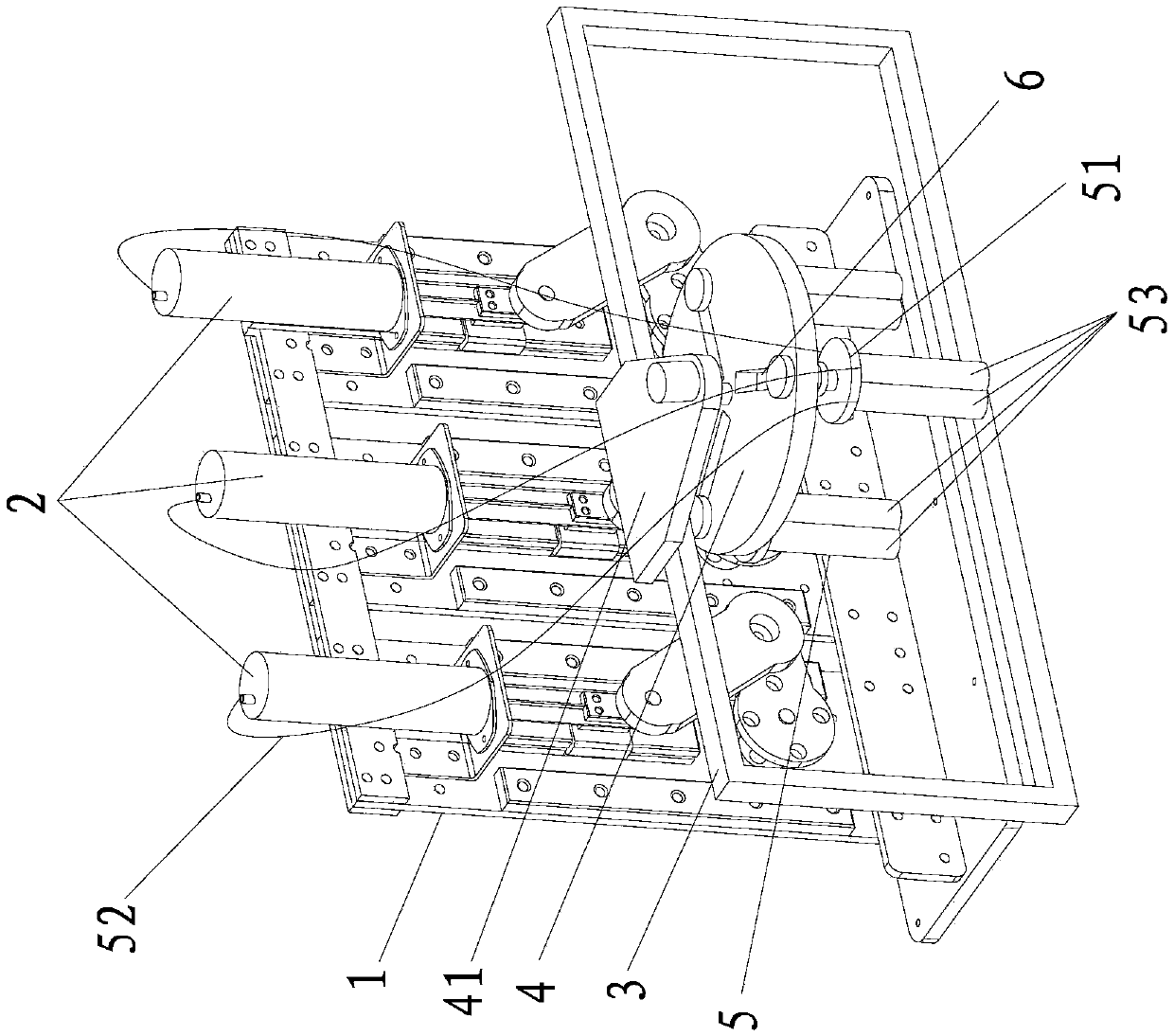

[0022] According to one embodiment of the present invention, a flexible manipulator system is provided. Such as Figure 1-2 As shown, the flexible manipulator system includes a platform base 1 , a first driving device 2 , a moving base 3 , a support plate 4 , and a three-chamber conjoined flexible arm 5 . The first driving device 2 is arranged on the platform base 1 .

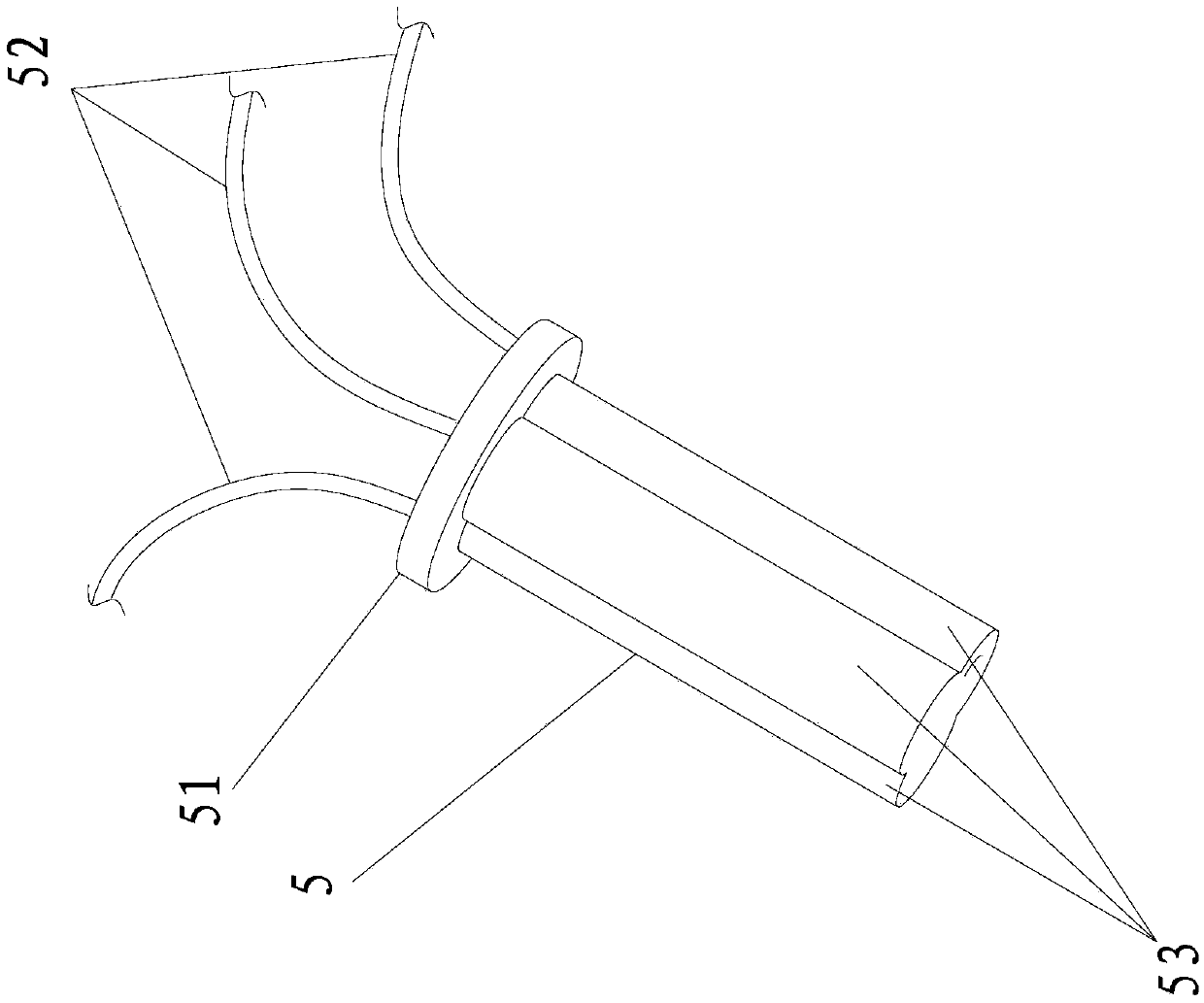

[0023] A multifunctional flexible manipulator of the present invention includes at least one set of three-chamber conjoined flexible arms 5 , preferably, three groups of three-chamber conjoined flexible arms 5 are selected in this embodiment. The three-chamber conjoined flexible arm 5 is composed of three hoses 52 and three independent flexible grippers 53. The inner chambers of each flexible gripper 53 are hollow structures, and the inner chambers of the three independent flexible grippers 53 are arranged in parallel. together, and the central axes of three independent flexible grippers 53 form an equilatera...

Embodiment 2

[0035] The difference between this embodiment and the first embodiment lies in that the multifunctional flexible manipulator of the present invention only includes a set of three-chambered conjoined flexible arms 5 .

[0036] After adopting the above-mentioned structure, a group of three-cavity conjoined flexible arms 5 are extended to the pipeline 8 or the gap, which can capture rock paintings in caves, ancient tombs, karst caves and other places with unknown dangers, and can reduce the detection of dangerous areas. The danger of personnel is improved, the safety of detection personnel is improved, and the interference effect on the exploration object is minimized to maintain the original appearance.

Embodiment 3

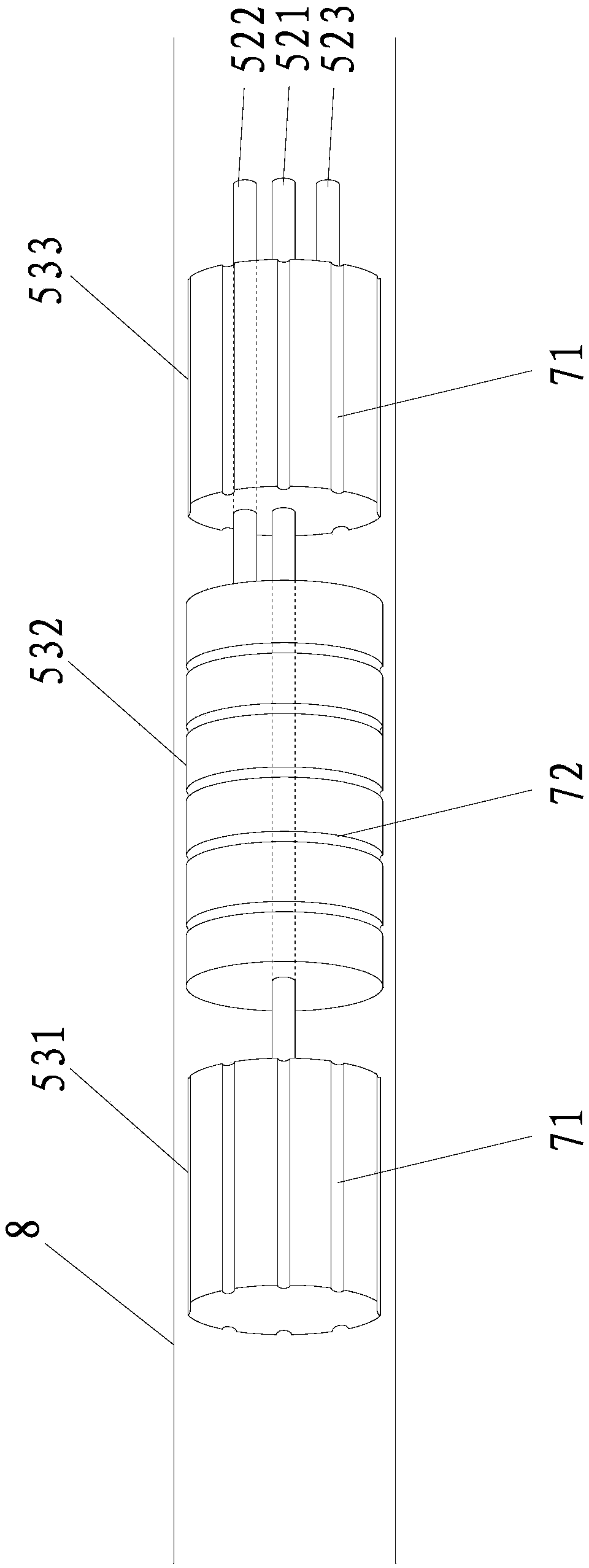

[0038] Such as image 3 As shown, the difference between this embodiment and Embodiments 1 and 2 is that the three-chamber conjoined flexible arm 5 is three independent single-chamber first flexible grippers 531, second flexible grippers 532 and third flexible grippers. The handles 533 are spliced end-to-end through corresponding first hoses 521, second hoses 522 and third hoses 523 respectively, and the first flexible gripper 531, the second flexible gripper 532 and the third flexible gripper 533 all have One opening is connected with the corresponding first hose 521, second hose 522 and third hose 523 respectively, one end of the first hose 521 is connected with the opening of the first flexible handle 531, and the other end is passed through Through the inner cavity of the second flexible gripper 532 and the third flexible gripper 533 and connected with the external gas power device, one end of the second flexible gripper 522 is connected with the opening of the second fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com