Projection point-to-point measurement plumb appliance and processing device thereof

A vertical and point-to-point technology, applied in measuring devices, plumb lines, metal processing equipment, etc., can solve problems such as the penetration of the grinding head, reduce the grinding efficiency of the plumb body, and the cumbersome processing process, so as to improve processing efficiency and improve Grinding and polishing efficiency, a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, creative features, purpose and efficacy of the invention easy to understand, the following are combined Figures 1 to 12 The invention is further described.

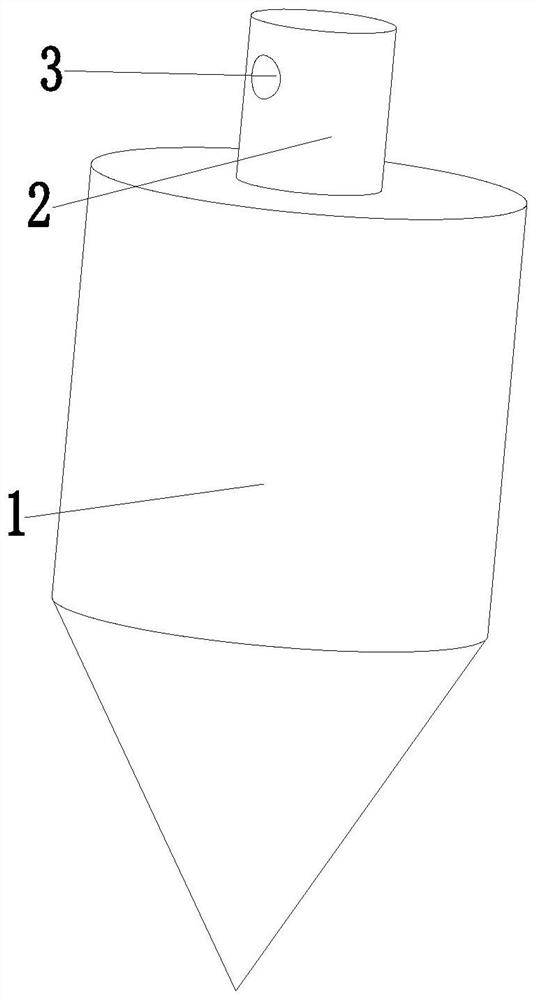

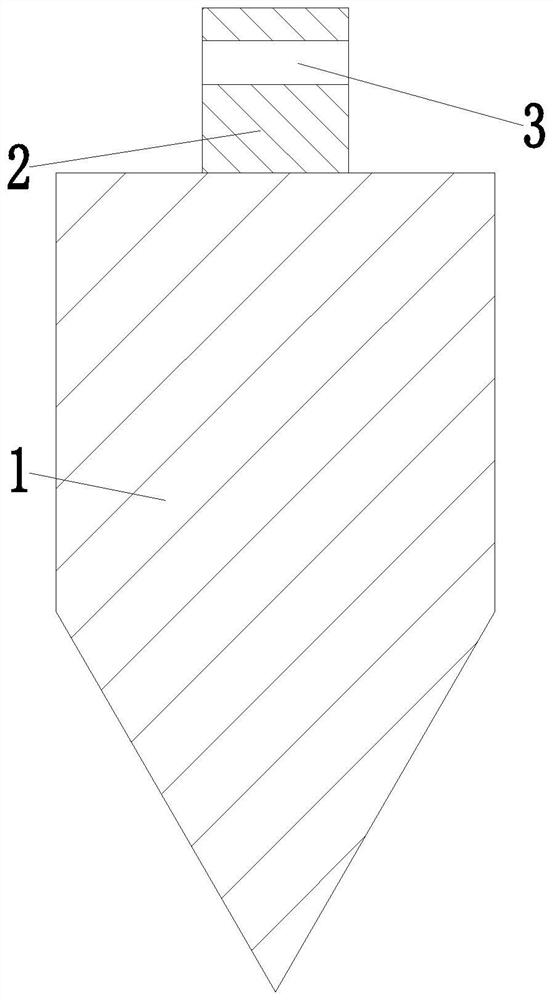

[0033] see Figure 1 and Figure 2 The utility model relates to a projection point-to-point measuring plumb apparatus, which comprises a plumb body 1, a connecting rod 2 and a connecting hole 3. The top of the plumb body 1 is provided with a connecting rod 2, and the connecting rod 2 is provided with a connecting hole 3.

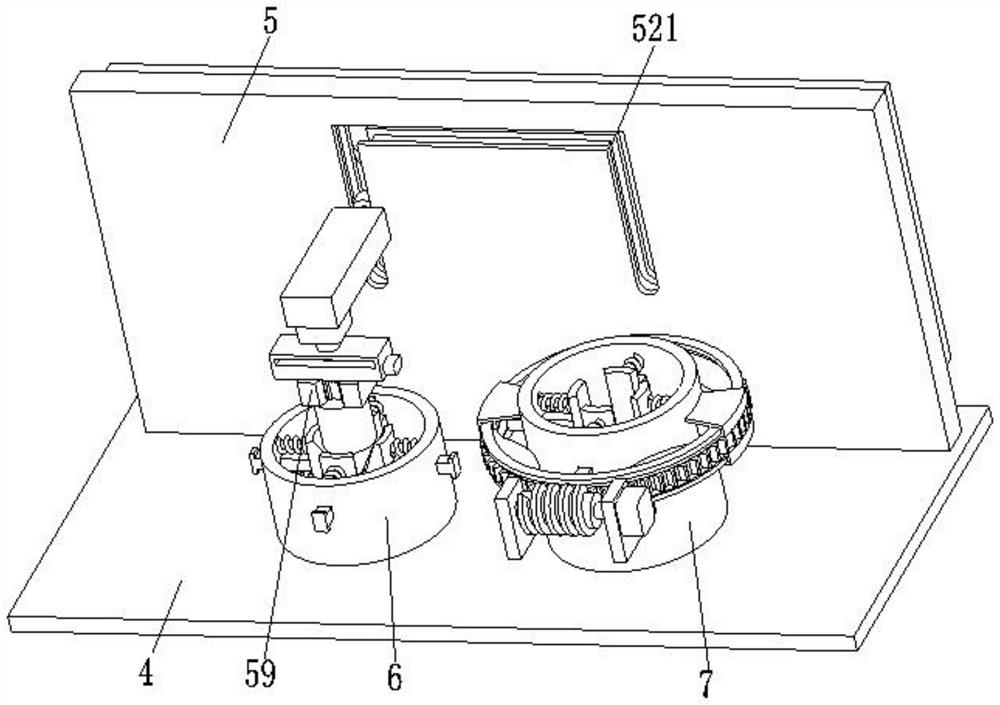

[0034] see Figure 3 、 Figure 4 and Figure 5 During the processing of the above plumb apparatus, a special processing device needs to be used. The processing device includes an operation platform 4, a transmission mechanism 5, a grinding mechanism 6 and a polishing mechanism 7. The rear end of the operation platform 4 is provided with a transmission mechanism 5, the left end of the operation platform 4 is equipped with a grinding mechanism 6, and the right end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com