Environment-friendly plate processing equipment

A plate processing and environmental protection technology, applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of increased labor intensity, poor effect, inconvenient grinding, etc., to reduce labor intensity, convenient use, comprehensive grinding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

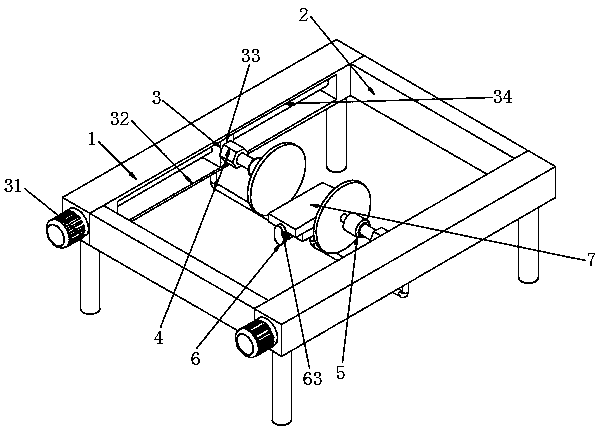

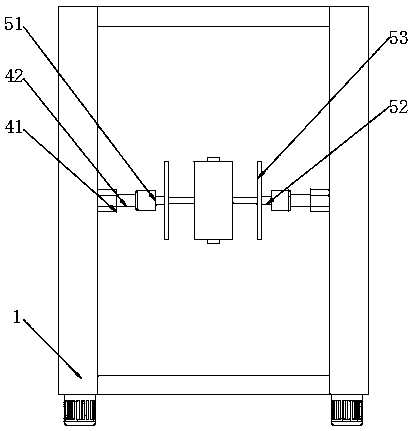

[0019] Such as Figure 1-4 As shown, an environment-friendly plate processing equipment includes a mounting frame 1, a connecting frame 2, a moving assembly 3, a telescopic assembly 4, a grinding assembly 5, a platform assembly 6 and a plate body 7. The mounting frame 1 is provided with two parallel, And the two ends of the two mounting frames 1 are connected by the connecting frame 2, the mounting frame 1 is equipped with a mobile assembly 3, and the mobile assembly 3 is equipped with a telescopic assembly 4, and the telescopic assembly 4 is equipped with a polishing assembly 5, and the two mounting frames An unclosed cavity is formed between 1 and the two connecting frames 2, and a platform assembly 6 is arranged in the middle of the cavity;

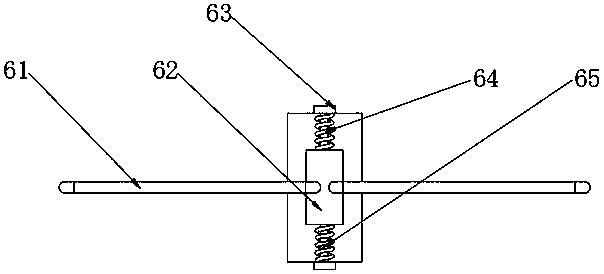

[0020] Wherein, the platform assembly 6 includes a support frame 61, a base 62, a pressing plate 63, a return spring 64, a round rod 65, an annular clamping groove 66, an annular clamping plate 67 and a socket 68, the base 62 is locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com