Electric kettle cover outer surface grinding device

An outer surface, electric kettle technology, which is applied in the directions of grinding machines, grinding workpiece supports, grinding machine parts, etc., can solve the problems of poor grinding effect of the outer surface of the electric kettle lid, fit and grinding, etc., and improve the adaptability range. , Fully polished, the effect of polishing is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

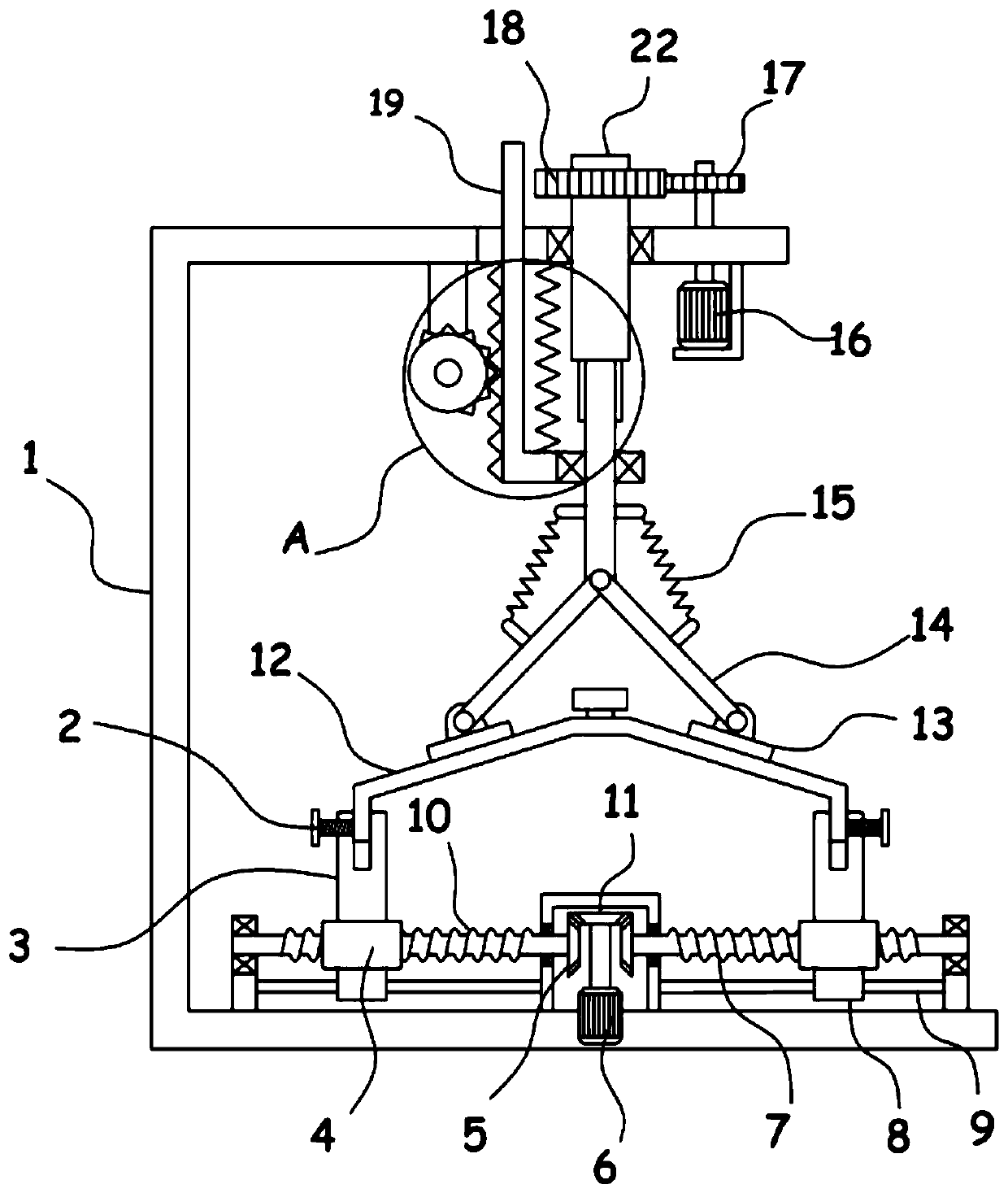

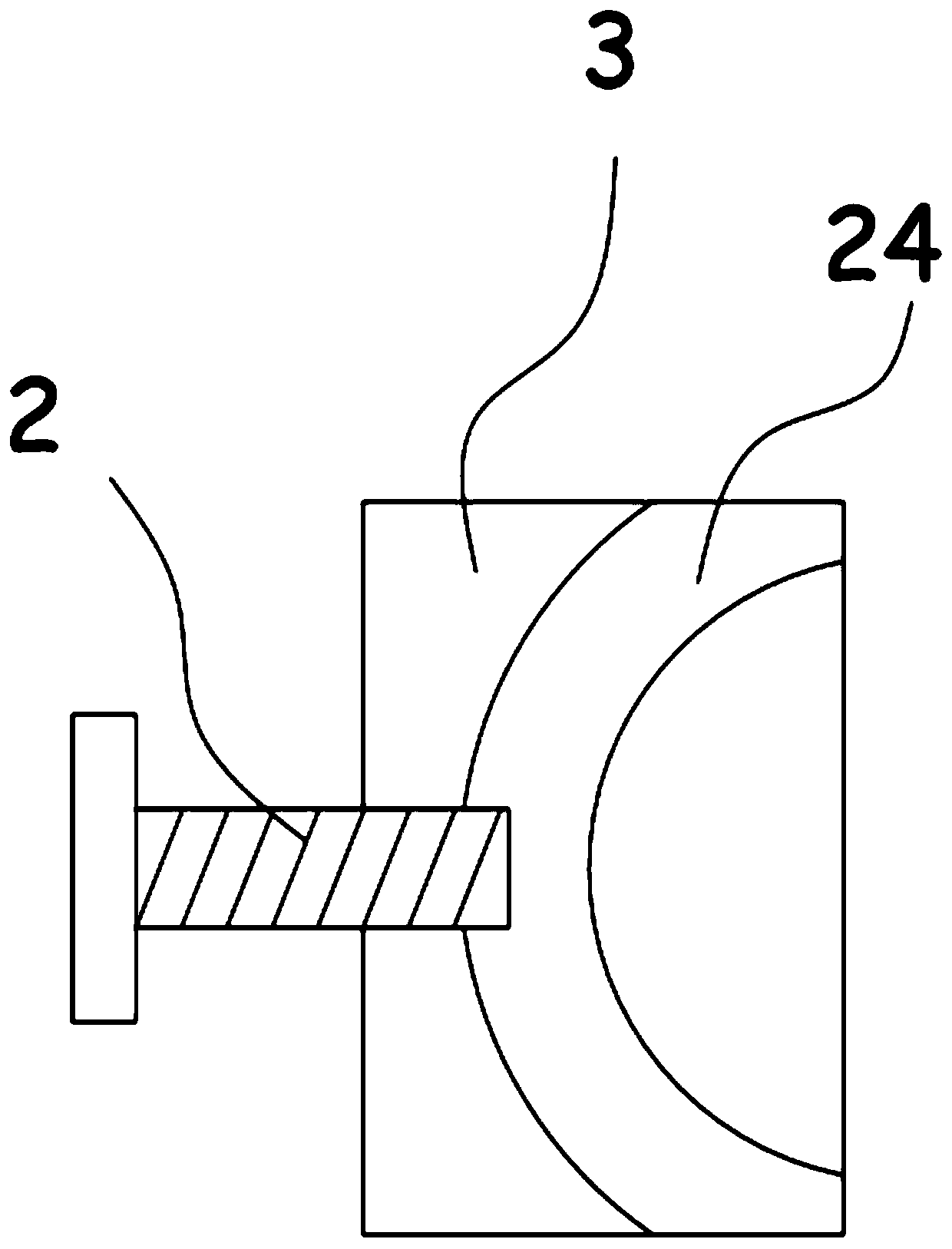

[0023] see Figure 1-4 , a device for grinding the outer surface of the lid of an electric kettle, comprising an operating frame 1 on which a servo motor 6 is fixed, and the operating frame 1 is provided with a clamping mechanism including two limit seats 3 for clamping the lid 12 , the servo motor 6 is driven and connected with an adjustment mechanism for adjusting the distance between the two limit seats 3, the operating frame 1 is pivotally connected with a transmission sleeve 22 driven by the drive mechanism, and the transmission sleeve 22 is connected with a rotating Shaft 20, the lower end of the rotating shaft 20 is connected with a polishing assembly for polishing the outer surface of the pot lid 12, and the operating frame 1 is provided with a reciprocating mechanism for driving the rotating shaft 20 to reciprocate up and down.

[0024] When the device is grinding the outer surface of the pot lid 12, the pot lid 12 is clamped and fixed by the clamping mechanism provid...

Embodiment 2

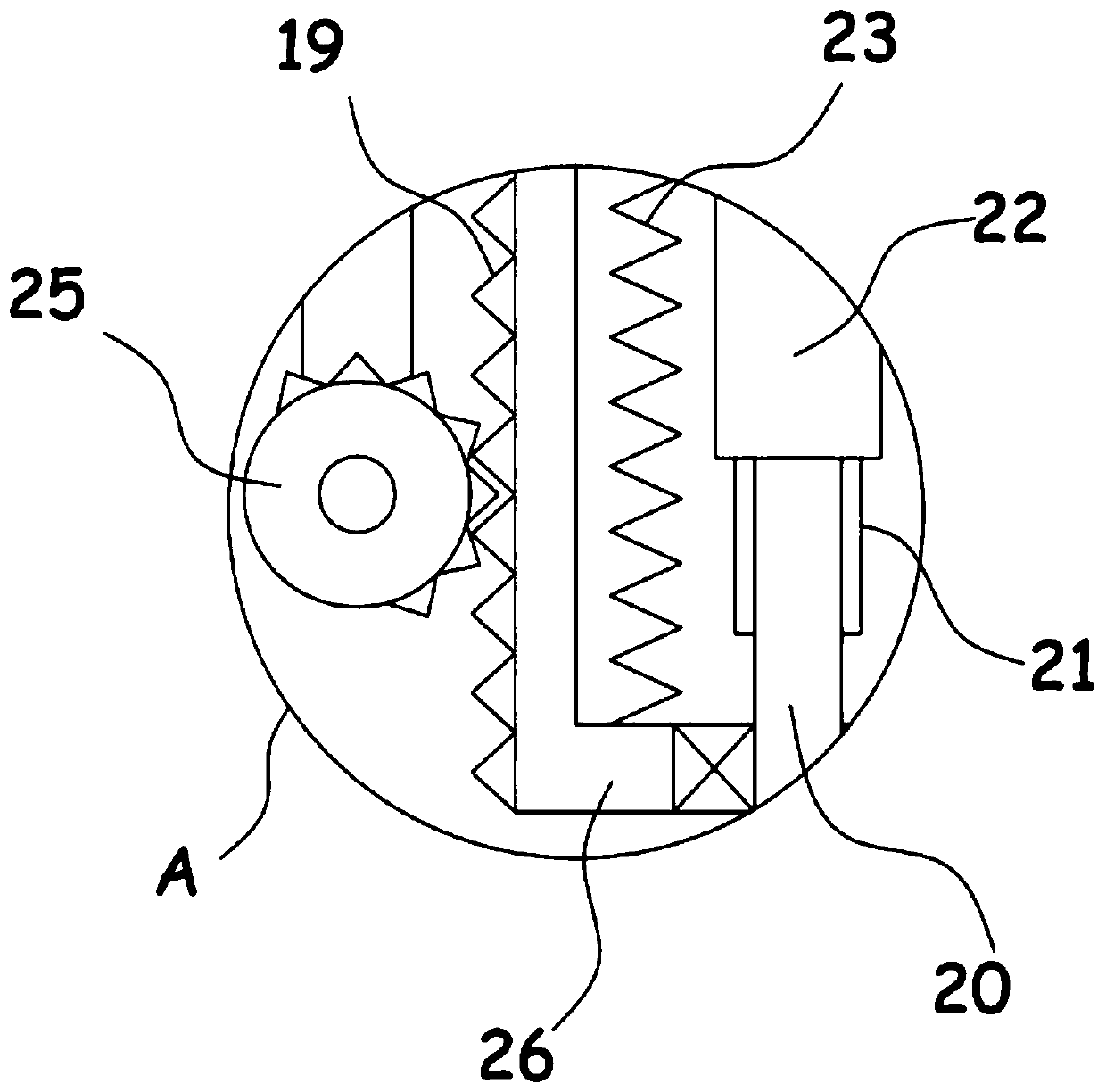

[0030] When the grinding plate 13 is at a specific height, the grinding plate 13 can only polish a local area on the pot cover 12. In order to ensure the comprehensive grinding effect of the pot cover 12, it is necessary to make the grinding plate 13 carry out grinding along the outer surface of the pot cover 12. The adjustment of the up and down height, for this reason, on the basis of embodiment 1, the reciprocating mechanism includes a limit frame 26, the rotating shaft 20 is pivotally connected on the limit frame 26, and the limit frame 26 is fixedly installed with a sliding penetrating frame 1. A toothed rack 19 is fitted with an incomplete gear 25 driven by a motor to mesh on the toothed rack 19 , and a return spring 23 is fixedly connected between the limiting frame 26 and the operating frame 1 .

[0031] The incomplete gear 25 is driven by the motor to rotate. When the incomplete gear 25 rotates counterclockwise to mesh with the rack 19, the rack 19 drives the limit fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com